Table of Contents:

- Introduction

- Types of 3D Printing Technologies

- Advantages and Limitations of 3D Printing Service

- Applications of 3D Printing Service

- Factors to Consider Before Choosing a 3D Printing Service

- Trends and Future of 3D Printing Service

- Conclusion

-

1.Introduction

A. Definition of 3D printing service.

3D printing service refers to a digital fabrication process used to create three-dimensional objects. This technology involves the creation of physical models from digital blueprints or computer-aided design (CAD) models. 3D printing service allows for the generation of three-dimensional objects by adding layers of material on top of one another until the desired shape is reached.

B. Brief history of 3D printing.

3D printing traces its origin back to 1986 when Chuck Hull invented the first-ever 3D printer. In the years that followed, advancements were made in the technology, which led to the development of several different printing methods. 3D printing has since revolutionized the manufacturing industry and has been adopted in a wide range of industries, including aerospace, automotive, healthcare, and education.

C. Importance of 3D printing service.

The advent of 3D printing service has proven to be a game-changer for the manufacturing industry. It has made it possible to design and prototype relatively complex shapes quickly, affordably, and with high accuracy. 3D printing service has also opened up new possibilities in manufacturing, including customization, distributed manufacturing, and hybrid manufacturing. These benefits have transformed the way businesses design, develop, and produce products. 3D printing service has also facilitated the creation of models for surgical planning in the medical sector, high-resolution prototypes in the automotive industry, and functional prototypes in the aerospace industry. 3D printing service has thus become an essential tool for businesses and industries looking to innovate and stay ahead of the competition.

-

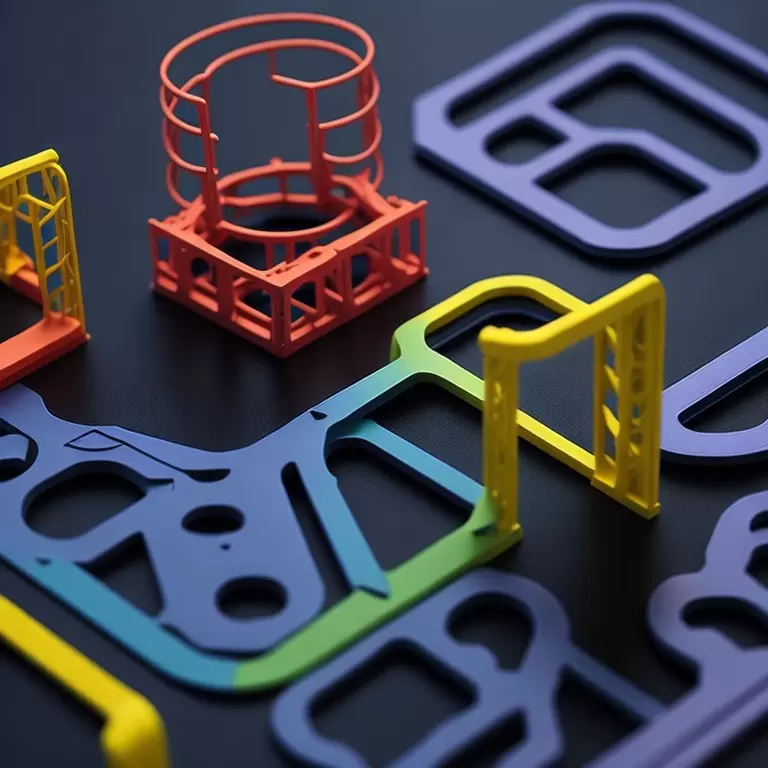

2.Types of 3D Printing Technologies

A. Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is the most widely used 3D printing technology. FDM works by melting thermoplastic material and depositing it layer by layer to build a 3D object. FDM printers are easy to use, affordable, and relatively slow. FDM technology is well-suited for small to medium-sized objects.

B.Stereolithography (SLA)

Stereolithography (SLA) uses a light-sensitive resin that is cured using a precisely directed laser or light source. SLA’s strength lies in its precision and the ability to create highly detailed and accurate models. SLA is most suitable for small objects, jewelry, and highly-detailed mechanical components.

C.Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) uses high-powered lasers to heat and melt powdered materials in a layer-by-layer process. SLS produces highly durable and strong objects, making it ideal for parts and components under high stress loads. SLS technology is being used in a variety of industrial and automotive applications.

D. Digital Light Processing (DLP)

Digital Light Processing (DLP) uses light-sensitive liquid resins that are cured by UV light. DLP allows for highly-precise and rapid prototyping, making it a popular choice for creating small objects, jewelry, and dental models.

E. Comparison of 3D printing technologies

When selecting a 3D printing technology, it is essential to consider factors such as speed, accuracy, cost, and material availability. FDM is the most accessible and affordable option, while SLA is best suited for highly detailed and intricate designs. SLS is ideal for creating durable and functional parts, and DLP is suitable for rapid prototyping with very high accuracy. Each technology has its unique strengths and limitations, and the choice of technology depends on the intended application.

-

3.Advantages and Limitations of 3D Printing Service

A. Advantages:

- Customizability: 3D printing service offers the ability to customize objects to meet specific needs and requirements.

- Affordability: 3D printing service can be relatively cheap due to reduced setup costs, eliminating the need for tooling and molding costs.

- Time-saving: 3D printing service can rapidly produce models and prototypes with accurate details and better shapes, resulting in faster project completion times.

- Sustainability: 3D printing service results in less waste production by printing only what is needed.

- Scalability: 3D printing service can be easily scalable, leading to the efficient production of smaller and larger batches of 3D printed objects.

.

B. Limitations:

- Limited material options: 3D printing service typically supports limited materials, which can impact the flexibility of design.

- Restricted size and shape: 3D printing service is limited by the size of the 3D printer and the shapes that the printer can produce.

- Difficulty with certain structures: 3D printing service struggles with printing some intricate structures, making it challenging to create more complex designs.

- Post-processing requirements: 3D printed objects may require post-processing, such as polishing and finishing, to achieve the desired visual effect.

- Need for specialized knowledge: 3D printing service requires specialized skills and knowledge, making it challenging for small businesses or individuals to use without additional training.

C. Challenges in 3D printing service

- Intellectual property risks: 3D printing service can pose significant challenges to intellectual property rights, making it difficult for companies to protect their designs.

- Quality control: 3D printing service typically requires monitoring and adjustment to achieve quality control.

- Lack of standardization: 3D printing service lacks standardization, making it challenging to compare the quality of services offered by different companies.

- Regulatory barriers: The 3D printing service is subject to various regulations and restriction, which can impact the creation of medical devices, aerospace, and automotive parts.

- Costs: While 3D printing service has become relatively affordable, the cost of the technology and materials can still be a challenge for smaller businesses and individuals.

-

4.Applications of 3D Printing Service

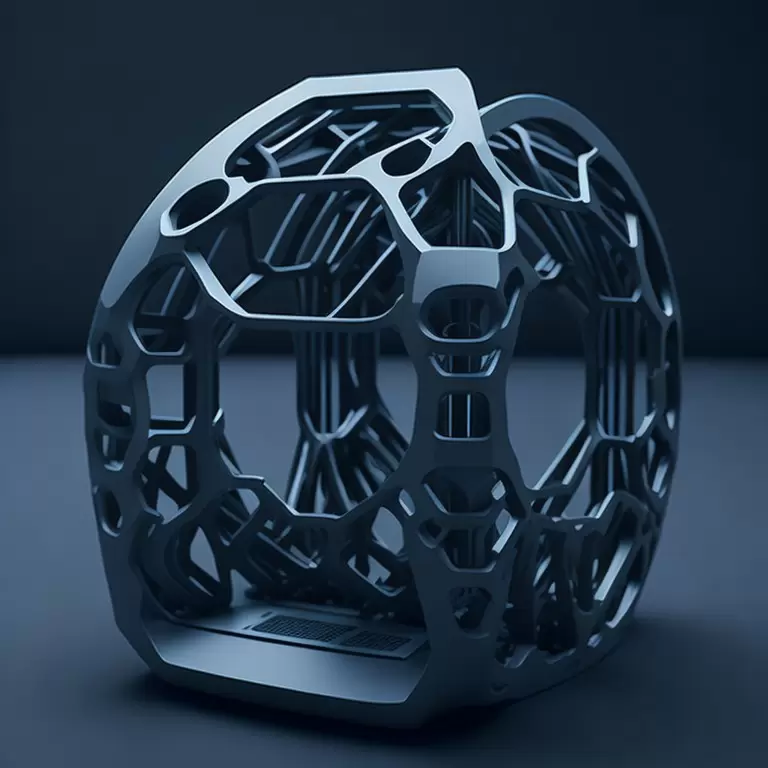

A. Prototyping: 3D printing service is widely used in the prototyping phase of product development. It enables designers to create functional prototypes quickly and efficiently, allowing them to test and fine-tune product designs before committing to large-scale manufacturing.

B. Manufacturing: 3D printing service is also used in the manufacturing industry for small-scale production runs, especially for highly customized or unique products.

C. Medical: The medical industry widely uses 3D printing service to create accurate anatomical models for surgical planning, as well as creating implants, prosthetics, and other medical devices. 3D printing service enables medical professionals to create highly-customized, patient-specific devices and implants.

D. Aerospace: 3D printing service is one of the most significant technological advancements in the Aerospace industry. It has enabled the creation of complex and lightweight components that are essential in aerospace engineering, which significantly reduces the overall weight of the aircraft.

E. Automotive: The automotive industry has been an early adopter of 3D printing service technology, utilizing the process to create concept models, prototypes, and high-performance parts. 3D printing service has the potential to revolutionize the automotive industry by enabling fully customized vehicle production.

F. Consumer Products: 3D printing service allows for the creation of customizable and unique consumer products, such as jewelry, eyewear, clothing, and toys. 3D printing service enables personalized and bespoke design, thereby redefining how consumers perceive and purchase products.

Overall, 3D printing service has expanded the possibilities of product creation, with a wide range of applications in different industries.

If you need about 3D printing service,You can click on the V1 Prototype website to find it. v1 prototype.Provide Sla, Sls, Fdm, Rapid Plastic & Metal 3D Printing Service, High Accuracy, No Tooling And Saving Cost. Fast Delivery, Ship Within 3days.

-

5.Factors to Consider Before Choosing a 3D Printing Service

Choosing a 3D printing service can be a daunting task, but there are specific factors you should consider before making your decision. Here are the top factors to consider:

A. Material options: Different 3D printing services can print with different materials, which can impact the flexibility of design. Before choosing, consider what materials the service can work with to ensure they meet your needs.

B. Quality and accuracy: The quality and accuracy of the final product are crucial in 3D printing service. Examine reviews, past projects, and samples to see if the company can meet your expectations in regard to quality and accuracy.

C. Lead time and cost: Consider the turnaround time for the company to complete your project and the cost to determine whether it is viable for your budget and timeline.

D. Post-processing capabilities: Some 3D printing services may require additional post-processing, such as painting or sanding, to achieve the desired visual effect. Consider whether the service offers these capabilities or if they require additional services.

E. Customer service and support: Good communication and customer service are essential when choosing a 3D printing service. Consider the responsiveness of the company’s customer service and whether they provide ongoing support and assistance.

In summary, choosing a 3D printing service requires thorough research and evaluation. By considering material options, quality and accuracy, lead time and cost, post-processing capabilities, and customer service, you can select the best 3D printing service for your needs.

-

6.Trends and Future of 3D Printing Service

While 3D printing service has already been a disruptive and transformative technology, several trends are likely to shape its future.

A. Shift towards sustainable materials: As the world becomes more environmentally conscious, the use of sustainable materials in 3D printing is becoming more critical. Research is ongoing to find more sustainable materials like bioplastics, recycled plastics, and other eco-friendly materials.

B. Integration with Artificial Intelligence (AI): AI is being integrated into 3D printing service technology to enhance the design process. AI tools can help generate automated designs, with software offering predictions on optimal print settings, reducing iterations and saving time.

C. Expansion of 3D printing in healthcare: 3D printing service has shown great potential in the healthcare industry. Experts predict that 3D printing service will continue to grow in healthcare through the production of customized implants and prostheses, more precise anatomical models, and the ability to produce on-demand drugs.

D. Growth of 3D printing service bureaus: Demand for 3D printing service continues to grow in various industries, increasing the need for 3D printing service bureaus. These service providers can help businesses that don’t have the resources, time, or expertise in-house, to tackle 3D printing projects.

In summary, the future of 3D printing service is likely to be dominated by trends such as an increased use of sustainable materials, the integration of artificial intelligence, the expansion of 3D printing in healthcare, and the growth of 3D printing service providers. As these trends become mainstream and new markets emerge, we can expect 3D printing service to become even more transformative and accessible to all kinds of businesses and industries.

-

7.Conclusion

A. Recap of key takeaways:

In conclusion, 3D printing service has revolutionized manufacturing and product design, offering a customizable, affordable, and flexible alternative to traditional manufacturing methods. We’ve covered the most popular types of 3D printing technologies, the advantages, limitations, and applications in various industries. We’ve also explored what factors to consider when selecting a 3D printing service and the trends that will shape the future of 3D printing service.

B. Future outlook of 3D printing service:

The future of 3D printing looks bright, with continued innovation and advancement of the technology in various industries. As the technology evolves, we can expect lower costs, increased speed, and the use of more sustainable materials. We anticipate 3D printing service to continue to drive new business models, transform traditional manufacturing processes, and play a significant role in medicine, aerospace, and other innovative industries. 3D printing will continue to push the boundaries of what is possible, and as a result, create opportunities for businesses globally to realize significant benefits.