Table of Contents:

- Introduction

- Types of Plastic Mold Companies

- Factors to Consider When Choosing a Plastic Mold Company

- The Plastic Mold Manufacturing Process

- Future of Plastic Mold Companies

- Conclusion

–

1.Introduction

Plastic mold companies are vital players in the manufacturing industry, providing a range of services that enable the production of high-quality plastic products. These companies utilize various techniques to create molds for plastic products, such as injection molding, blow molding, and compression molding. They also offer design and engineering services, ensuring that clients’ needs are met at every stage of the manufacturing process.

In this comprehensive guide, we will explore the different types of plastic mold companies, factors to consider when choosing a company, top plastic mold companies, the plastic mold manufacturing process, and the future of plastic mold companies.

–

2.Types of Plastic Mold Companies

Plastic mold companies can be broadly categorized into three types: injection molding companies, blow molding companies, and compression molding companies. Each of these companies has its unique advantages and is suited for different types of plastic products.

Injection molding companies use high-pressure injection molding machines to create intricate and detailed plastic parts with high accuracy and consistency. They are ideal for producing high volume and complex parts used in the automotive, medical, and aerospace industries.

Blow molding companies use a blowing technique to create hollow plastic parts with a wide range of shapes and sizes. They are commonly used to produce plastic bottles, containers, and tanks.

Compression molding companies use heat and pressure to mold thermosetting plastics into various shapes and sizes. They are often used to produce electrical and automotive components that require high strength and durability.

–

3.Factors to Consider When Choosing a Plastic Mold Company

Choosing the right plastic mold company is crucial to the success of your manufacturing project. Here are some essential factors to consider when choosing a plastic mold company:

Experience and Expertise: Look for a company with extensive experience and expertise in the type of plastic product you want to produce. Check their portfolio and references to see if they have successfully handled similar projects.

Quality of Products and Services: Look for a company that offers high-quality products and services. Check their certifications, quality control procedures, and testing methods to ensure that their products meet industry standards.

Customer Service: Choose a company that provides excellent customer service. They should be responsive, communicate effectively, and be willing to address any concerns or issues that may arise during the manufacturing process.

Cost and Affordability: Look for a company that offers competitive pricing and transparent pricing models. Avoid companies that provide low-cost services but compromise on quality.

–

4.The Plastic Mold Manufacturing Process

The plastic mold manufacturing process involves several stages, including designing the mold, building the mold, injection molding, and quality control and testing.

Designing the mold: The first stage involves designing the mold, which is done using computer-aided design (CAD) software. The design should be accurate and precise, taking into account the material, dimensions, and functionality of the final product.

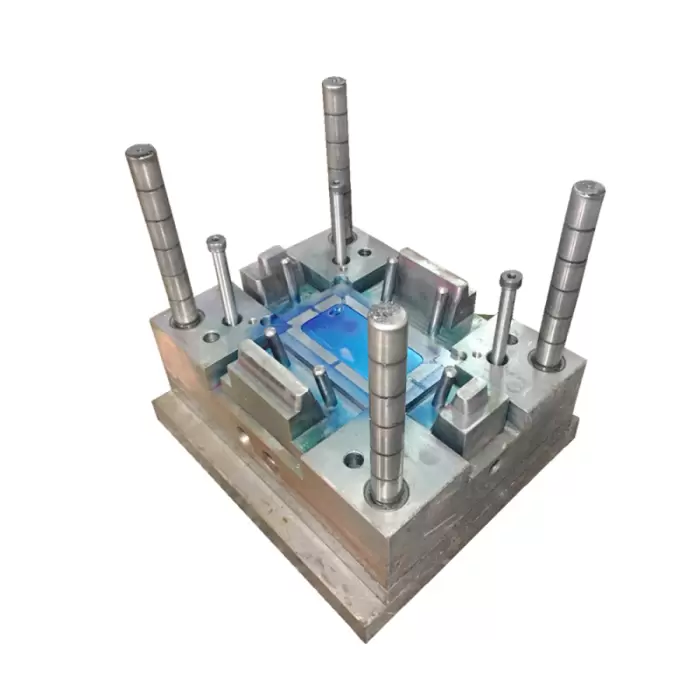

Building the mold: The next stage involves building the mold, which is usually done using steel or aluminum. The mold must be sturdy and durable enough to withstand the high pressure and temperature during the injection molding process.

Injection molding process: The injection molding process involves melting plastic pellets and injecting them into the mold cavity. The mold is then cooled, and the plastic part is ejected from the mold. This process is repeated several times to produce the desired number of plastic parts.

Quality control and testing: The final stage involves quality control and testing, which is essential to ensure that the products meet industry standards. The products are inspected for defects, such as cracks, warps, and discoloration. They are also tested for strength, durability, and functionality.

–

5.Future of Plastic Mold Companies

The future of plastic mold companies looks promising, with emerging technologies and increasing awareness of sustainability and environmental concerns. Here are some trends that are likely to shape the future of plastic mold companies:

Emerging Technologies: The use of emerging technologies, such as 3D printing and digital manufacturing, is likely to transform the plastic mold manufacturing process. These technologies offer more flexibility, speed, and cost-effectiveness, making it easier to produce customized plastic parts.

Sustainability and Environmental Concerns: The increasing awareness of sustainability and environmental concerns is likely to drive demand for eco-friendly plastic products. Plastic mold companies will need to adopt more sustainable practices, such as using biodegradable materials and reducing waste.

Click on the V1 Prototype website to gain more Plastic Mold information.

–

6.Conclusion

In conclusion, plastic mold companies play a crucial role in the manufacturing industry, providing a range of services that enable the production of high-quality plastic products. When choosing a plastic mold company, it is essential to consider factors such as experience and expertise, quality of products and services, customer service, and cost and affordability.

The future of plastic mold companies looks promising, with emerging technologies and increasing awareness of sustainability and environmental concerns likely to drive demand for more eco-friendly plastic products. By staying abreast of these trends, plastic mold companies can continue to provide high-quality products and services that meet the changing needs of the manufacturing industry.