This guide delves into the revolutionary potential of 3D printing in mass manufacturing. You'll explore how 3D printing can transform traditional production methods, enhancing efficiency, reducing costs, and opening up new possibilities. Discover the latest advances in additive manufacturing and how they are impacting the world of mass production. With this comprehensive guide, you'll gain a deeper understanding of the role of 3D printing in revolutionizing production.

I. Introduction to the Revolutionary Role of 3D Printing in Mass Manufacturing

A. What is 3D Printing?

3D printing, or additive manufacturing, is a cutting-edge technology that fabricates three-dimensional objects layer by layer from digital models. Unlike traditional manufacturing methods, 3D printing adds material selectively, allowing for intricate designs and customization.

B. The Evolution of 3D Printing in Mass Manufacturing

The journey of 3D printing in mass manufacturing began with prototyping but has evolved into a transformative force. Initially utilized for creating prototypes, the technology has advanced to support large-scale production, revolutionizing traditional manufacturing processes.

C. The Transformative Impact of 3D Printing on Mass Production

3D printing has disrupted the conventional mass production model by offering speed, flexibility, and cost-effectiveness. Its transformative impact extends beyond rapid prototyping, influencing how companies approach design, production, and supply chain logistics on a massive scale.

II. Advantages of 3D Printing in Mass Manufacturing

A. Reduced Lead Times and Enhanced Flexibility

3D printing enables the rapid production of components, reducing lead times significantly. The flexibility to modify designs and iterate quickly contributes to accelerated product development cycles, a crucial advantage in the fast-paced world of mass manufacturing.

B. Cost-effective Production of Complex Parts

The ability to produce complex geometries in a single manufacturing step distinguishes 3D printing. This complexity is achieved without the need for intricate tooling, leading to substantial cost savings compared to traditional manufacturing methods.

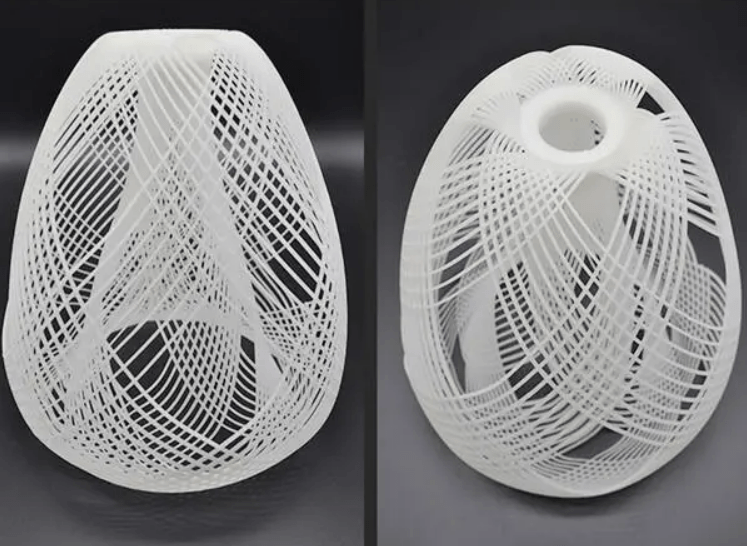

C. Improved Design Freedom and Functionality

Design constraints often limit traditional manufacturing, but 3D printing unlocks new possibilities. Complex and organic shapes that were once challenging or impossible are now feasible, resulting in products with enhanced functionality and improved performance.

D. Localized Manufacturing and Sustainability

3D printing supports localized manufacturing, reducing the dependence on centralized production facilities and minimizing transportation costs. This shift towards local production aligns with sustainability goals, reducing the carbon footprint associated with mass manufacturing.

III. Innovations in 3D Printing for Mass Manufacturing

A. Advanced Materials for High-performance Applications

Innovations in materials have expanded the capabilities of 3D printing for mass manufacturing. High-performance polymers, metals, and composites enable the production of components with superior strength, durability, and thermal properties.

B. High-volume Production with Automated 3D Printing Lines

Automation has played a crucial role in scaling up 3D printing for mass production. Automated 3D printing lines, equipped with robotic systems, enable continuous and efficient manufacturing of large quantities with minimal human intervention.

C. Additive Manufacturing for Disruptive Product Designs

The adoption of additive manufacturing techniques has led to disruptive product designs in mass manufacturing. Customization, personalization, and the ability to tailor products to specific market segments are now achievable, setting the stage for a new era of consumer engagement.

IV. Case Studies in Revolutionary Mass Manufacturing with 3D Printing

A. Leading Companies Embracing 3D Printing for Mass Production

Explore case studies of industry leaders successfully implementing 3D printing in mass production, showcasing the technology's impact on their efficiency, cost-effectiveness, and product innovation.

B. Breakthrough Innovations in the Automotive Industry

Witness how 3D printing has revolutionized the automotive sector, from rapid prototyping to the production of end-use parts, resulting in lighter vehicles, improved fuel efficiency, and innovative design elements.

C. Revolutionizing Medical Device Manufacturing

Delve into how 3D printing has transformed the medical device manufacturing landscape, facilitating the production of patient-specific implants, prosthetics, and cutting-edge medical devices with unprecedented precision.

D. Expanding the Reach of Consumer Product Designs

Discover how 3D printing has empowered designers and manufacturers to create consumer products with unique designs, customizable features, and efficient production processes, ultimately enhancing the consumer experience.

V. Conclusion

A. Summary of Key Learnings

In conclusion, 3D printing has emerged as a game-changer in mass manufacturing, offering advantages in speed, cost, and design flexibility. The technology's impact is evident across industries, with companies achieving groundbreaking innovations and redefining the traditional production landscape.

B. Resources for Further Exploration

For those eager to explore the revolutionary role of 3D printing in mass manufacturing further, a wealth of resources awaits. Industry conferences, research publications, and online forums provide avenues for continued learning and staying abreast of the latest advancements in this dynamic field.