Table of Contents:

- Introduction to Rapid Prototyping

- Types of Rapid Prototyping

- Advancements in Rapid Prototyping

- Applications of Rapid Prototyping

- Preparing for Rapid Prototyping

- Quality Control in Rapid Prototyping

- Pros and Cons of Rapid Prototyping

- Future of Rapid Prototyping

- Conclusion

-

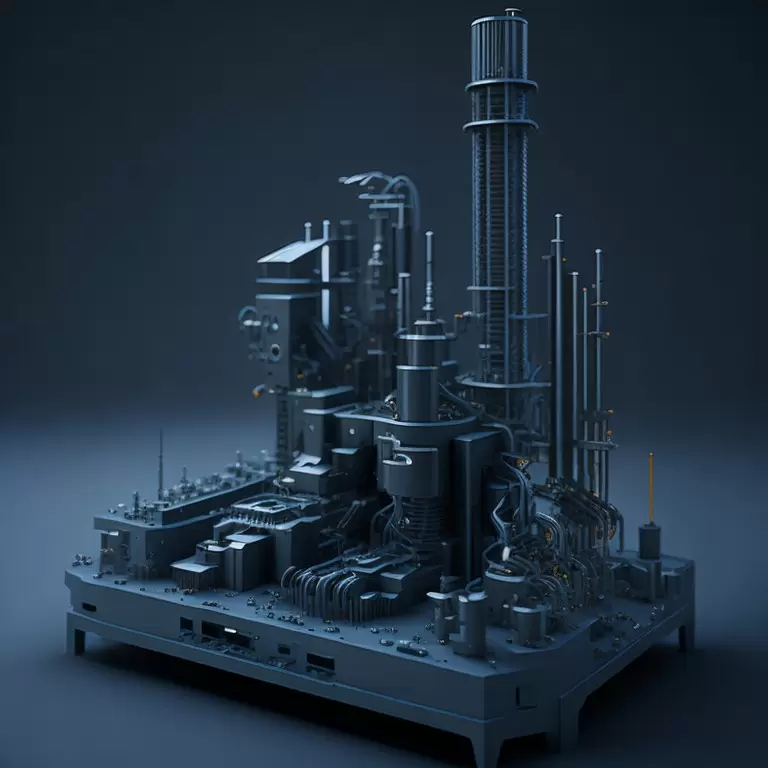

1. Introduction to Rapid Prototyping:

Rapid prototyping is a technology-driven process that enables quick and cost-effective creation of physical models or parts directly from digital 3D data. This article seeks to provide an in-depth guide to rapid prototyping, including its importance, types, advancements, applications, preparing for rapid prototyping, quality control, pros and cons, and future trends.

Definition of Rapid Prototyping:

Rapid prototyping is a process that simplifies the creation of prototypes by creating three-dimensional models using computer-aided design (CAD) technology.

Importance of Rapid Prototyping in Industrial Model:

Rapid prototyping plays a critical role in the product development process by allowing for the quick creation of physical parts, saving time and money. Companies can test and evaluate the design of a product and make changes before producing the final product in mass production.

-

2. Types of Rapid Prototyping:

Fused Deposit Modeling:

Fused deposit modeling (FDM) is a 3D printing process that involves building parts by layering melted plastic filament. FDM is widely used in the production of prototypes, largely because it is relatively easy to operate, fast, and inexpensive.

Stereolithography:

Stereolithography (SLA) is a process used to create 3D parts using a laser and photosensitive resin. The laser selectively hardens areas of the liquid resin, resulting in the formation of the required part.

Selective Laser Sintering:

Selective laser sintering (SLS) is a rapid prototyping process that creates 3D objects by layering powdered material, typically nylon, and using a high-energy laser to melt the material in the necessary areas.

Continuous Liquid Interface Production:

Continuous liquid interface production (CLIP) is a process that uses 3D printing technology and a liquid resin to produce high-quality end-use parts at speeds that rival traditional injection molding.

-

3. Advancements in Rapid Prototyping:

Integration of 3D Printing Technology:

Rapid prototyping is constantly evolving, with 3D printing technology significantly impacting the industry by optimizing speed and accuracy in the production process. 3D printing has effectively reduced the cost of rapid prototyping and made it more accessible to small and medium-sized businesses.

Use of Sustainable Materials:

As concerns about sustainability grow, the use of sustainable materials in the rapid prototyping process has become essential. Eco-friendly materials such as bioplastics and recycled plastics are gaining popularity in the industry.

-

4. Applications of Rapid Prototyping:

Aerospace and Automotive Industry:

Rapid prototyping has enabled the aerospace and automotive industries to produce complex models of parts and components at a higher speed and lower cost. These industries require a high level of precision and quality, which rapid prototyping can deliver.

Healthcare Industry:

The healthcare industry uses rapid prototyping to produce customized medical devices, implants, and prosthetics. By using rapid prototyping, traditional manufacturing can be bypassed, and patients can receive tailored medical solutions.

Product Design Industry:

The product design industry aims to create innovative products that can capture audiences’ attention. By using rapid prototyping, product designers can quickly build prototypes that meet the clients’ requirements, test product design concepts, and bring ideas to market quickly.

-

5. Preparing for Rapid Prototyping:

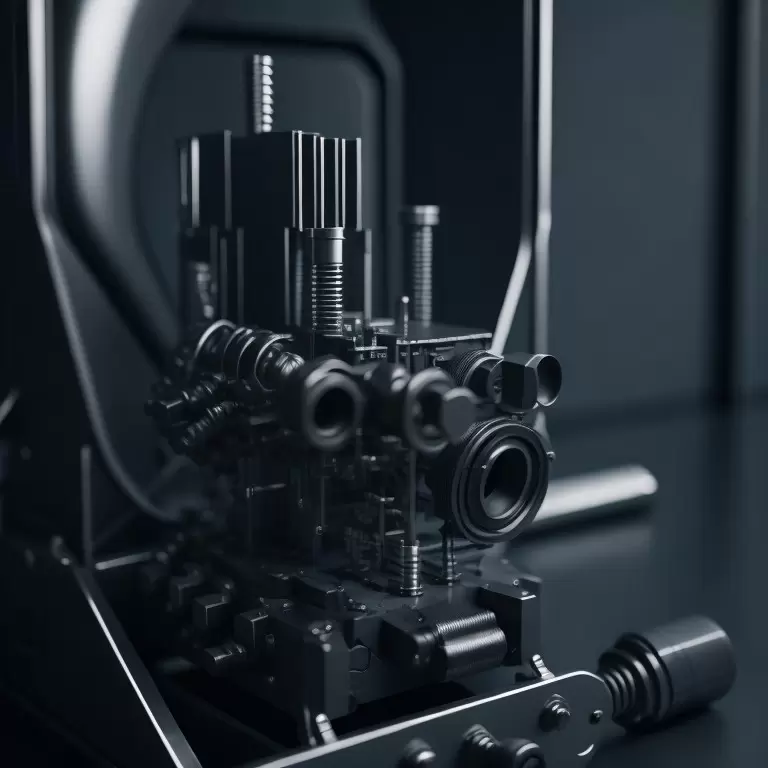

Designing for Rapid Prototyping:

Designers must consider several factors during the design process to ensure the production of an accurate and functional prototype. Factors such as thickness, material strength, and design complexity must align with the rapid prototyping process.

Materials Selection:

Choosing the right materials is essential in rapid prototyping. Material selection should be based on the functional requirements of the prototype, production volume, and cost.

Prototyping Process:

A successful rapid prototyping process must be streamlined and efficient. The system must be designed to minimize any problems, such as inaccuracies, poor quality, or damage to the prototype.

-

6. Quality Control in Rapid Prototyping:

Inspection and Testing Techniques:

Quality control is a crucial aspect of rapid prototyping. Various inspection and testing techniques such as visual inspection, dimensional inspection, and chemical analysis can be used to ensure the parts’ quality.

Standards and Regulations:

Manufacturers must adhere to industry standards and regulations during the rapid prototyping process to ensure the safety and quality of the final product.

-

7. Pros and Cons of Rapid Prototyping:

Advantages:

Rapid prototyping offers several benefits, including quick turnaround times, low initial costs, customizable designs, and testing prototypes before investing in mass production.

Disadvantages:

The integration of rapid prototyping requires a high initial investment, potential inaccuracies in prototype production, and limited manufacturing scalability.

-

8. Future of Rapid Prototyping:

Challenges and Opportunities:

The future of rapid prototyping remains bright but presents challenges such as sustainability and material selection. Opportunities to improve productivity, accuracy, and reduce waste exist, along with new developments in processes, software, and technology.

New Developments in Rapid Prototyping:

New developments in rapid prototyping include the integration of machine learning and artificial intelligence, along with increased sustainability through the use of bio-based materials.

If you need more about Rapid Prototyping In Industrial Model information ,You can click on the V1 Prototype website to find it.

-

9. Conclusion:

Rapid prototyping is a technology-driven process that simplifies the creation of physical parts directly from digital 3D data. With advancements in 3D printing technology and the use of sustainable materials, rapid prototyping is becoming more accessible to small and medium-sized businesses across various industries. The process offers numerous benefits, including quick turnaround times, low initial costs, and customizable designs. Companies can use rapid prototyping to test and evaluate the design of a product, making changes before producing the final product in mass production. However, challenges such as sustainability and material selection must be addressed. As the industry continues to evolve and new developments arise, the future of rapid prototyping looks promising.