Blog Center

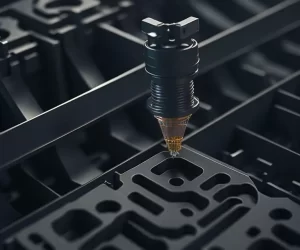

Complete Guide to SLS 3D Printing: Everything You Need to Know

Selective Laser Sintering (SLS) 3D Printing is a type of additive manufacturing technology that utilizes a high-powered laser to selectively sinter powdered material, typically polymers, metals, or ceramics, layer by layer to form a three-dimensional object.

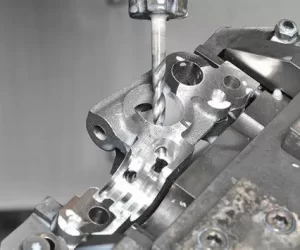

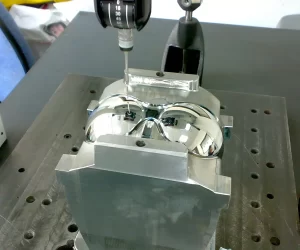

Precision CNC Machining: A Comprehensive Guide to Choosing the Right Supplier

Advancements in technology have revolutionized the manufacturing industry, and one of the most impressive developments has been the rise of precision CNC machining.

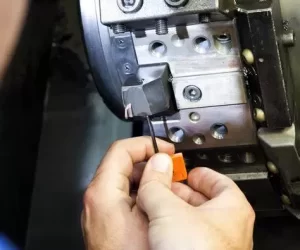

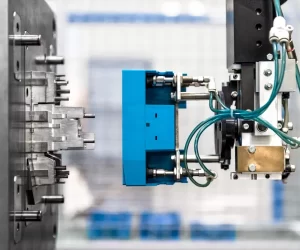

An Extensive Guide to 2K Injection Molding: Process, Benefits, and Applications

2K injection molding is a highly precise manufacturing process that involves the use of two different materials in a single plastic injection molding process.

A Comprehensive Guide to Injection Moulding: Definition, Process and Applications

Injection moulding is a manufacturing process used to create parts or products by injecting molten material into a mould cavity. It is one of the most widely used manufacturing processes in the world, producing everything from automotive parts to medical devices and consumer goods.

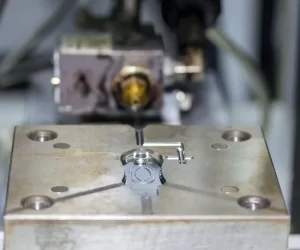

Understanding the Importance of Injection Molding Screw in Manufacturing

Injection molding screw is a critical component in the injection molding process, which involves the injection of molten material into a mold to create a part or product.

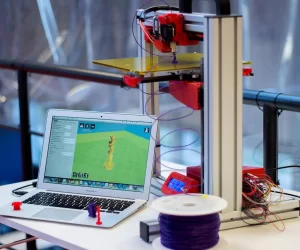

An Overview of Rapid Prototyping: Definition, Working Principles, and Applications

Rapid prototyping is a manufacturing technique that allows for the quick and cost-effective production of physical prototype models for design and product development.

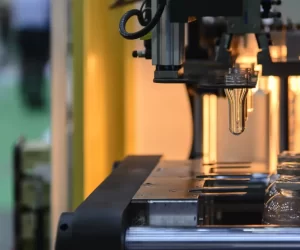

Plastic Extruders: An Overview of their Types, Functions, and Applications

Plastic extrusion is a manufacturing process used to produce continuous plastic profiles with a predefined cross-sectional shape. The plastic extrusion process involves melting plastic pellets and then pushing them through a die that creates a specific profile.

An Overview of Aluminum Injection Molds: Properties, Advantages, and Applications

Injection molding is a widely used manufacturing process in which melted plastic or metal is injected into a mold to form a desired shape. Aluminum injection molding, also known as aluminum die casting, refers to the process of injecting aluminum alloys into molds to make complex and precise-shaped components.

Aluminium Die Casting: Benefits, Applications, and Innovations

Aluminum die casting is a process that involves the injection of molten aluminum into a high-quality steel mold, or die, under high pressure. The process is used to produce complex and intricate shapes with high precision and accuracy. Aluminium die casting is widely used across various industries, including automotive, aerospace, consumer goods, and electronics, among others.

Revisiting Injection Moulding: Understanding How the Process Works

Injection moulding is a widely used manufacturing process that involves shaping plastic parts by injecting molten plastic material into a mould. The process is commonly used to make products ranging from toys, electronic devices, automotive parts, and medical equipment, among others.

Custom Injection Molding: A Complete Guide to the Materials, Process, and Applications

Custom injection molding is a versatile and widely used manufacturing process that involves injecting molten plastic into a mold cavity to produce high-quality and reliable parts with intricate and complex geometry. The process is considered ideal for producing parts at high volumes, with low unit costs, excellent surface finish, and dimensional accuracy.

Know about the Injection Moulding: Similarities, Techniques, and Applications

Injection moulding is a manufacturing process that involves injecting molten material, usually thermoplastic or thermosetting polymers, into a mould cavity under high pressure.

The Definitive Guide to Die Casting Process: Techniques, Applications, and Best Practices

Die casting is a widely used manufacturing process for producing complex and precise metal components with high efficiency and accuracy.

The Definitive Guide to Molding Product Manufacturing: Types, Processes, and Applications

Molding products are industrial products and parts manufactured using specialized molding manufacturing processes such as injection molding, blow molding, thermoforming, rotational molding, and extrusion molding.

Plastic Mold Manufacturers: A Comprehensive Guide to Materials, Processes, and Best Practices

A plastic mold manufacturer is a specialized company that produces industrial parts and products by using a mold, which can be made of a variety of materials, such as plastic, metal, or ceramic.

The Ultimate Guide to Moulding Processes: Techniques, Materials, and Applications

Moulding can be defined as the process of creating a specific shape by pouring a liquid or pliable material into a form or mold, which is then cooled or hardened to create a solid object. This technique can be used in a variety of industries including manufacturing, automotive, packaging, medical, and consumer goods.

The Complete Guide to Casting Materials: Processes, Properties and Applications

Casting is a manufacturing process in which a liquid material is poured into a mold to create a specific shape. There are a variety of casting materials available, each with its own unique properties and distinct advantages. In this guide, we will discuss the various casting materials, the casting process, and their applications.

The Ultimate Guide to Aluminium Extrusion: Techniques, Applications and Benefits

Aluminium extrusion is the process of shaping aluminum into a specific profile, using a die and a press. The result is a single, continuous piece with an intricate cross-section. In this guide, we will explore the various techniques, applications, and benefits of aluminum extrusion.

Understanding the Factors Affecting Injection Molding Machine Cost

A quality injection molding machine is critical to the success of a manufacturing operation. These machines enable the production of high-quality and durable parts, while also reducing the overall production time and costs. However, understanding the factors that influence the cost of these machines can be challenging.

Exploring the Different Types of Injection Moulding Techniques:Advanced Techniques&Practical Tips

Injection moulding is a manufacturing process in which molten plastic is injected into a mould cavity to create a specific shape. The process is ideal for creating high-volume, low-cost, and complex plastic parts with excellent durability features. Injection moulding is a versatile technology, making several applications possible across different industries.