Blog Center

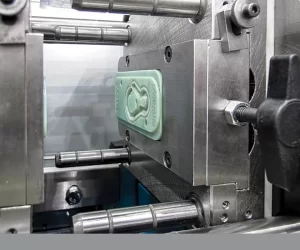

Plastic Tooling: Types, Techniques, and Applications

Plastic tooling refers to the process of creating custom molds and tools used in the manufacturing of plastic parts and products.

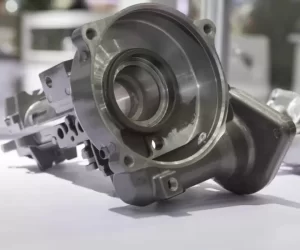

What is Die Casting: A Comprehensive Guide about process,Quality Control&Design Considerations

Die casting is a manufacturing process that involves injecting molten metal into a mold or die to produce complex and precisely shaped metal parts.

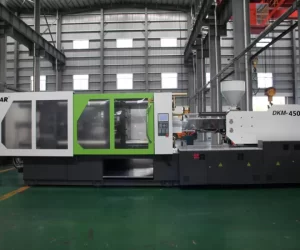

An Overview of Injection Moulding Machines: Types and Applications

The injection moulding process involves the melting of plastic granules and injecting the melted plastic into a mould to form a specific shape and size.

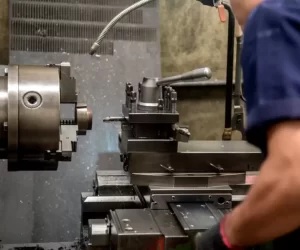

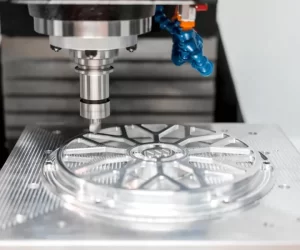

CNC Programming: A Comprehensive Guide to Techniques, Maintenance, and Troubleshooting

CNC Programming, also known as Computer Numerical Control Programming, is the process of creating computer programs to control machine tools that can manufacture objects with high precision and accuracy.

Plastic Molding Factory: The Basics of Manufacturing Plastic Products

Plastic molding is the process of shaping plastic materials into specific forms through the use of specialized tools, equipment, and techniques.

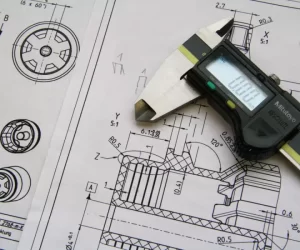

Engineering Drawing Basics: An Introduction to Technical Drawing for Engineers

Engineers and manufacturers continue to use drawings to communicate how to create things.

Exploring Injection Molded Plastic Manufacturing: Processes, Quality Control, Applications, and Future Trends

Injection molding is a manufacturing process that involves injecting molten plastic into a mold to create a final product.

Plastic Parts: An Overview of Types, Applications, and Manufacturing Processes

Plastic parts are an essential component in various manufacturing industries, ranging from consumer goods to medical equipment, automotive, and electronics.

Pet Injection Molds: Design, Applications, and Future Trends in the Growing Pet Industry

Pet injection molds, also known as PET preform molds, are specialized tools used to produce preforms or finished products made of polyethylene terephthalate (PET) thermoplastic resin.

From Concept to Reality: CNC Prototyping in China

CNC prototyping refers to the process of creating a physical model or an actual product from a digital design using computer-controlled machines.

The Importance of Injection Molding Temperature: Factors, Effects, and Optimization Strategies

Injection molding is a widely used manufacturing process for producing high-quality plastic parts in large quantities.

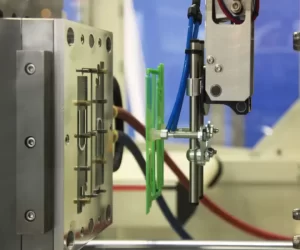

Injection Molding Components: Selection, Maintenance, and Care

Injection molding is a manufacturing process used to produce parts by injecting molten material into a mold cavity under high pressure.

Exploring the World of Plastic Texture: Types, Techniques, and Applications

Plastic texture refers to the surface of a plastic material that is intentionally manipulated to have a particular texture or pattern.

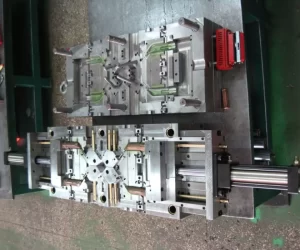

Mastering Injection Molding Tooling: Design, Production, Optimization, and Costs

ection molding tooling is a method widely used in the manufacturing industry to produce parts from thermoplastic materials.

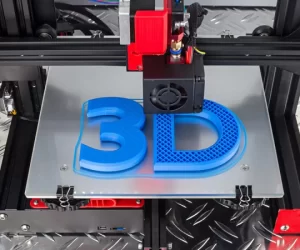

Advantages and Disadvantages of 3D Printing

3D printing is a rapidly growing technology that allows the creation of three-dimensional objects from digital files.

Plastic Manufacturing Process: From Raw Materials to Final Product

As a highly versatile material, plastic has become an integral feature of our everyday lives.

Die Casting Machines: Components, Processes, and Applications

Die casting machines are essential tools in modern manufacturing that enable the mass-production of high-quality metal castings with consistent accuracy and surface finish.

The Economics of Plastic Injection Molding: Understanding the True Cost

Plastic injection molding is a manufacturing process used to produce precise and complex plastic components by injecting molten plastic into a specially designed mold.

Die Casting Products: An Overview of Types, Materials, and Applications

Die casting is a metal casting process that involves injecting molten metal under high pressure into a mold cavity, forming the metal into the desired shape.

Injection Molding Lifters: Design, Operation, and Applications

Injection molding lifters are mechanical components that are used to lift or move specific features of a molded part during the ejection process.