Table of Contents:

- Introduction

- Types of Plastic Tooling

- Plastic Tooling Techniques

- Applications of Plastic Tooling

- Advantages and Disadvantages of Plastic Tooling

- Future Outlook for Plastic Tooling

- Conclusion

-

1. Introduction

Plastic tooling refers to the process of creating custom molds and tools used in the manufacturing of plastic parts and products. The process involves the use of specialized machinery and equipment to produce a mold or tool, which is then used to create plastic products using techniques such as injection molding, blow molding, rotational molding, thermoforming, and compression molding. Plastic tooling is an essential component of the plastics manufacturing industry, and with the increasing demand for plastic products, the demand for plastic tooling is also on the rise.

A. Definition of Plastic Tooling

Plastic tooling is the process of producing molds and tools used in the manufacturing of plastic products.

B. Importance of Plastic Tooling

Plastic tooling plays a crucial role in the production of plastic products. Without plastic tooling, it would be impossible to produce large quantities of uniform plastic products efficiently. Plastic tooling allows manufacturers to produce plastic products with high precision and accuracy, which is essential for many industries such as aerospace, medical, and automotive.

C. Overview of the Different Types of Plastic Tooling

There are different types of plastic tooling techniques, including injection molding, blow molding, rotational molding, thermoforming, and compression molding. Each of these techniques has its advantages and disadvantages and is suitable for different types of plastic products.

-

2. Types of Plastic Tooling

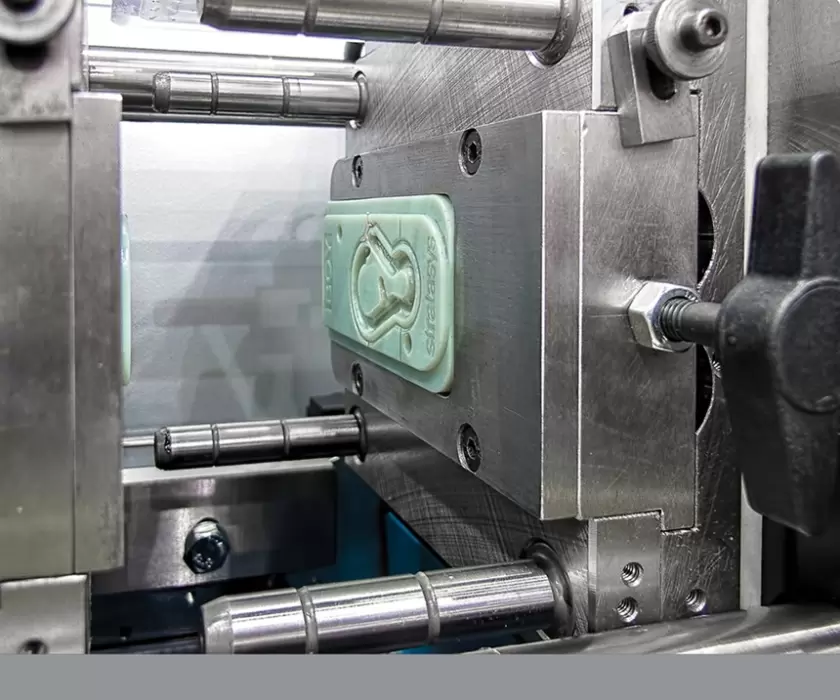

A. Injection Molding:Injection molding is the most commonly used plastic tooling technique. The process involves melting plastic pellets and injecting the molten plastic into a mold using high pressure. The plastic then solidifies in the mold and is ejected as a finished product.

B. Blow Molding:Blow molding is another popular plastic tooling technique used to produce hollow plastic products such as bottles, containers, and tubes. The process involves melting plastic and extruding it into a parison or tube. The parison is then inflated using compressed air, taking the shape of the mold cavity.

C. Rotational Molding:Rotational molding is a plastic tooling technique used to create large, hollow plastic products such as tanks, containers, and playground equipment. The process involves rotating a partially filled mold around two perpendicular axes, causing the plastic to evenly coat the mold cavity. After cooling, the finished product is removed from the mold.

D. Thermoforming:Thermoforming is a plastic tooling technique that involves heating a sheet of plastic and then placing it over a mold. A vacuum is then applied, pulling the plastic sheet down over the mold and taking its shape. After cooling, the finished product is removed from the mold.

E. Compression Molding:Compression molding is a plastic tooling technique used to create large, flat plastic products such as panels, sheets, and films. The process involves placing the plastic material into a mold cavity and then applying heat and pressure to the mold until the plastic hardens.

.

3. Plastic Tooling Techniques

A. Design Considerations for Plastic Tooling:When designing a plastic product, several factors need to be considered that will affect the selection and design of the plastic tooling. These factors include the type of plastic material being used, the desired shape and size of the product, and the production volume needed.

B. Material Selection for Plastic Tooling:Different plastic materials have different properties, such as their ability to withstand heat, flexibility, and durability. The plastic material selection needs to be considered before designing the tooling.

C. Mold Making:Mold making involves the creation of the mold or the tool that will be used to shape the plastic into the desired product. The process requires precision engineering and the use of specialized equipment.

- Injection Mold Making:Injection mold making involves creating a mold that will be used in the injection molding process. The mold is made of two halves, a core, and a cavity. The mold is typically made of steel, which can withstand high temperatures and pressures.

- Blow Mold Making:Blow mold making involves creating a mold that is used in the blow molding process. The mold is typically made of aluminum and can withstand high temperatures and pressures.

- Rotational Mold Making:Rotational mold making involves creating a mold that is used in the rotational molding process. The mold is typically made of aluminum or steel and can withstand high temperatures and pressures.

- Thermoforming Mold Making:Thermoforming mold making involves creating a mold that is used in the thermoforming process. The mold is typically made of aluminum or wood and can withstand high temperatures and pressures.

- Compression Mold Making:Compression mold making involves creating a mold that is used in the compression molding process. The mold is typically made of steel and can withstand high temperatures and pressures.

D. Mold Maintenance and Repair:To ensure the longevity of the mold and the quality of the plastic products produced, mold maintenance and repair are crucial. The mold needs to be kept clean and free of any damage or debris. Regular maintenance and repair will help to extend the life of the mold and improve the efficiency of the plastic tooling process.

-

4. Applications of Plastic Tooling

A. Automotive Industry:The automotive industry is a significant user of plastic tooling, especially injection molding. Plastic parts made using plastic tooling are used in several applications, including interior and exterior trims, dashboard components, and engine parts.

B. Consumer Products Industry:Plastic tooling is also extensively used in the production of consumer products such as toys, household appliances, and electronic devices.

C. Medical Industry:The medical industry relies heavily on plastic tooling for producing medical equipment, devices, and implants. The high-precision plastic parts produced using plastic tooling techniques are essential to ensure the safety of patients.

D. Aerospace Industr:The aerospace industry uses plastic tooling to manufacture parts such as airplane interiors, cockpit components, and structural components. The lightweight and durable plastic parts produced using plastic tooling techniques are ideal for the aerospace industry.

E. Packaging Industry:The packaging industry uses plastic tooling to produce various plastic packaging products such as bottles, containers, and pouches.

If you need about Plastic Injection Molding Services,You can click on the V1 Prototype website to find it.

-

5. Advantages and Disadvantages of Plastic Tooling

A. Advantages:Plastic tooling offers several advantages, including flexibility in product design, cost-effectiveness, and high-volume production.

B. Disadvantages:The disadvantages of plastic tooling include long lead times for tooling production, high initial setup costs, and limited material options.

-

6. Future Outlook for Plastic Tooling

A. Technological Advancements:Technological advancements in plastic tooling are paving the way for new techniques, materials, and customization options. Advances in 3D printing, automation, and robotics are revolutionizing the plastic tooling process.

B. Environmental Sustainability:The plastic industry is under pressure to find alternatives to traditional plastic materials due to their adverse impact on the environment. The use of bioplastics and recycled plastics can help reduce the environmental impact of plastic tooling.

-

7. Conclusion

Plastic tooling is a crucial component of the plastics manufacturing industry. The different plastic tooling techniques and materials offer flexibility in product design, cost-effectiveness, and high-volume production. The use of plastic tooling has widespread applications in various industries such as automotive, consumer products, medical, aerospace, and packaging. While plastic tooling offers several advantages, there are also challenges such as long lead times for tooling production, high initial setup costs, and limited material options. The future outlook for plastic tooling is promising, with technological advancements and increasing emphasis on environmental sustainability.