Expert Mold Design Services

V1 specialize in providing top mold design and injection molding services. From conceptualization to production, we ensure that your project is executed with the highest level of quality and efficiency.

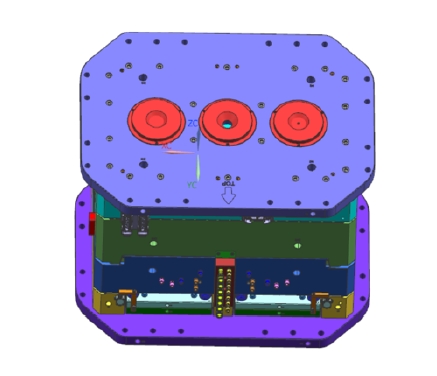

High quality molds begin with excellent design

The performance of the mold largely depends on the maturity of the design. Our designers' years of work experience are the decisive factor in the quality of V1 molds.

We work closely with clients in all aspects of design to ensure the highest quality molds are designed, maximizing cost-effectiveness during injection molding production and making them easy to maintain.

Our skilled design team has over 18 years of experience in designing customized molds. We provide a complete design solution:

- Feasibility analysis and optimal design solution.

- Fill Analysis & Model Flow Analysis.

- Mold Design 3D/2D (CAD, UG, etc. software...)

If necessary, our designers can also participate in the early stages of the project and provide support during the product development process to achieve feasible mold design, thereby saving you valuable time and project costs.

Professional and efficient mold design team

In V1, we take pride in our highly skilled professional mold design team, who work closely with clients to ensure the design process is completed efficiently and smoothly.

We pay special attention to the design structure, cooling system, and mechanical operation of each set of molds to ensure that the molds produce the highest quality products.

All molds are carefully designed to maximize their service life and facilitate maintenance.

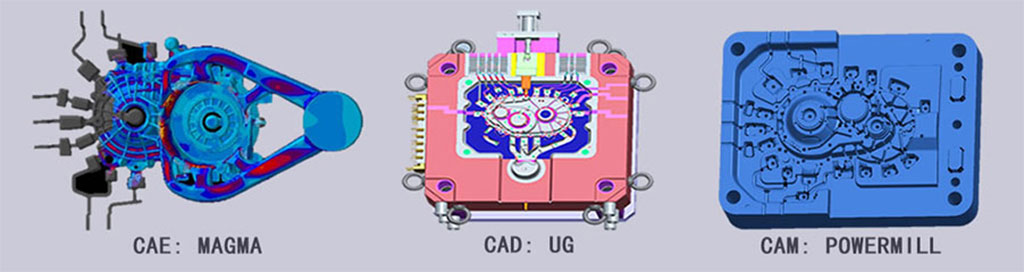

Comprehensive mold development software for CAD/CAE/CAM

- Computer Aided Design (CAD) Autocad, UG, Pro/E, Solidworks

- Computer Aided Analysis (CAE) Magma

- Computer Aided Processing (CAM) Powermill

- File support formats: stp/step/stl/iges/x_t/prt/dxf/dwg

Mold Flow Analysis: Perspective mold

Scientific calculations, repeated experiments to simulate rebound and surface defects, replace repeated experiments, improve mold life, and reduce development costs

- Fatigue Durability:Simulate and analyze the structural life, local fatigue cracks, and failure causes of injection molded parts, and design local reinforcement plans based on the analysis results.

- Optimization analysis:Identify potential weak links in the mechanical performance of product structure, and carry out targeted lightweight design optimization of structure and parameters.

- Prototype Virtual Test:Build a virtual testing platform to seek the optimal transmission structure for the weak links in the new product structure and shorten the prototype development time.

V1 Injection Mold process

1> Get Quote

Get a quote for tooling and first batch production with shipping estimates in 24 to 48 hours.

2> DFM analyze

Receive DfM documentation 24 to 72 hours after ordering tooling samples. Tooling begins when you sign off on the DfM report.

3> Mold making

You get 2 free samples per part for your approval. V1 keeps a “golden sample” part for additional quality inspection.

4> Mass Production

Your parts go into production after samples are approved by injection molding.

5> Quality control

We use the golden sample to verify future orders and provide additional QC checks.

6> Delivery

provides the convenience of having goods transported from our factory to your warehouse, saving time and effort for you.

Our Mold Design partners

With our rich experience of toolmaking, powerful local support from our overseas teams and reasonable price, we have established long term win-win business cooperation with worldwide well-know companies.