The application and advantages of Rapid Prototype in aerospace ship manufacturing

In order to meet the requirements of design verification in the aerospace field, prototype processing is an effective technical means. 3D印刷 technologyis a perfect embodiment of techniques and a direct and quick way for making prototypes to these special parts.

加えて, the processing of appearance model with equal proportion is a very good supplementary technique for public presentation and wind tunnel test. V1 Industrial has accumulated a wealth of experiences in assembly verification of cockpit and interior parts.

With the continuous development of science and technology, spaceships have become one of the important tools for human beings to explore the universe. In the design and manufacture of aerospace ships, using ラピッドプロトタイプ technology (ラピッドプロトタイプ) is an efficient method. This article will describe what ラピッドプロトタイピング is, its application to spaceship manufacturing, and its benefits and challenges.

What is Rapid Prototyping?

Rapid prototyping is a manufacturing technique that uses computer-aided design (CAD) software and equipment such as 3D printers to quickly create a physical model of a product. This technology can help designers quickly validate their designs, saving time and cost while improving product quality and production efficiency.

Application of Rapid Prototyping Technology in Aerospace Ship

In aerospace ship manufacturing, rapid prototyping technology can be applied in the following aspects:

1. Manufacture of aerospace ship components

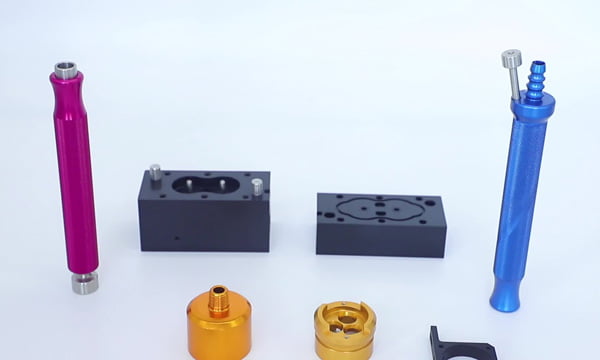

Rapid prototyping technology can manufacture parts of various shapes and structures, such as engine parts, mechanical parts, 電子部品, 等. These parts can be tested and verified before actual use to ensure their quality and reliability.

2. Shell manufacturing of spaceships

The shell of a spaceship is an important component, which needs to have good airtightness and protection performance. Rapid prototyping enables the manufacture of spacecraft shells of different shapes and sizes, which are tested and validated to ensure their quality and reliability.

3. Manufacture of control systems for spaceships

The control system of a spaceship is a complex system that requires precise design and fabrication. Rapid prototyping technology can manufacture control system components in different shapes and sizes, and test and verify them to ensure their quality and reliability.

Advantages of Rapid Prototyping Technology

Rapid prototyping technology has the following advantages in aerospace ship manufacturing:

1. Save time and cost

Rapid prototyping technology can quickly manufacture solid models of spaceships, saving the time and cost required by traditional manufacturing methods.

2. Improve product quality and production efficiency

Rapid prototyping technology can help designers verify their designs before actual product manufacturing, improve product quality and production efficiency.

3. Improve design flexibility

Rapid prototyping technology can manufacture parts and components of various shapes and structures, which improves the flexibility and innovation of design, and enables designers to design and modify products more quickly.

総括する, rapid prototyping technology is an efficient manufacturing technology in aerospace ship manufacturing. It can help designers verify designs, save time and cost, improve product quality and production efficiency, 等. しかし, it also needs to pay attention to the challenges of material limitations, precision limitations and manufacturing speed limitations. In aerospace ship manufacturing, the use of rapid prototyping technology needs to consider its advantages and disadvantages comprehensively to ensure its correct application in the design and manufacturing process.

プロフェッショナルなラピッドプロトタイピングサービス

3D プリントサービス: 高品質をご提供いたします, さまざまな業界や用途向けの高速かつ手頃な価格の 3D プリンティング ソリューション. 無料見積もりについては今すぐお問い合わせください.

Plastic & Metal Batch Production

V1 ラピッド プロトタイプは、人々の部品や製品の製造を支援します。 2006. 私たちは、世界で最も速く、最も信頼できる企業になることを目指して、品質とサービスの面で提供します。.

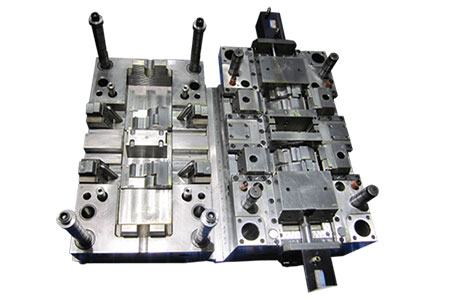

当社の会社と顧客ベースが成長するにつれて、サービスの範囲も拡大しました. 当社は現在、これほど幅広いプロトタイピングとオーダーメイドの少量生産ソリューションをすべて 1 つ屋根の下で提供できる世界で唯一の企業の 1 つです。. 弊社のハイテク ラピッド プロトタイピングおよび生産施設には以下が含まれます。 CNCフライス加工, 3D印刷 (SLAとSLS), 真空鋳造 (キャストウレタン), 板金、ラピッドツーリング、射出成形、従来のモデル製作、さまざまな仕上げ技術.

伝言を残す

接触

あなたのアイデアを実現するには、今すぐお問い合わせください, 私たちの専門チームが対応させていただきます 24 メールを受け取ってから数時間後.

- Eメール: info@v-1.com

- オフィスの住所: 22階, いいえ. 10 蓮湖路, 長安鎮, 東莞市, 広東省, 中国, 523850

- 工場住所: No.38, 六角路, 沙頭, 長安鎮, 東莞市, 広東省, 中国, 523850