Mechanical polishing

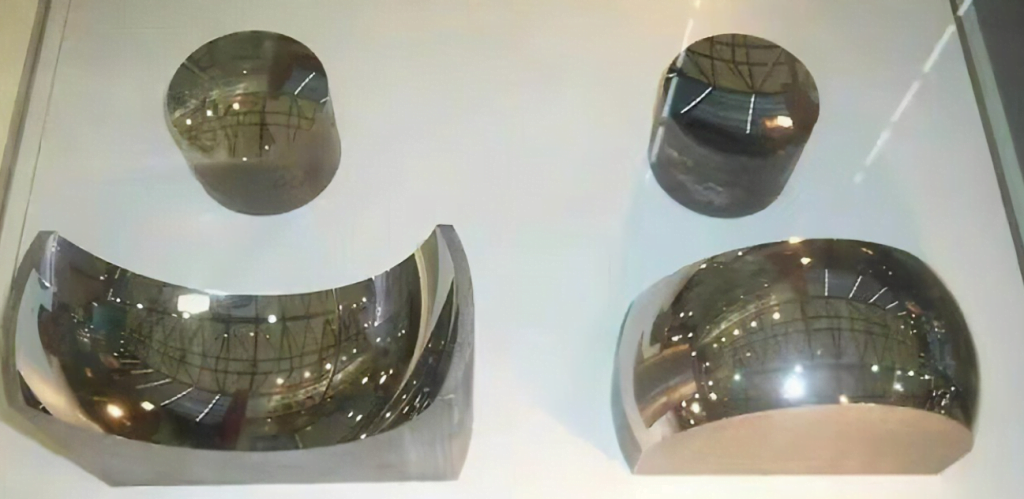

Mechanical cutting, polishing is to rely on material surface plastic deformation after removed by polishing the convex part of the smooth surface polishing method, commonly used article oil stone, wool wheel, abrasive paper, etc., with manual operation is given priority to, special components such as surface of solid of revolution, can use tools such as turntable, high surface quality can be used over lapping method. Super FINISH polishing is made of special abrasive tools, in the polishing liquid containing abrasive, pressed on the surface of the workpiece to be processed, for high-speed rotating motion. The surface roughness of Ra0.008μm can be achieved with this technique, which is the highest among all polishing methods. This method is often used in optical lens molds

Chemical polishing

Chemical polishing is to make the material in the chemical medium surface of the convex part of the concave part of the priority to dissolve, so as to get a smooth surface. The main advantage of this method is that it does not need complex equipment, can polish the workpiece of complex shape, can polish many workpiece at the same time, high efficiency. The core problem of chemical polishing is the preparation of polishing fluid. The surface roughness obtained by chemical polishing is generally 10μm

Electrolytic polishing

The basic principle of electrolytic polishing is the same as that of chemical polishing, that is, the surface of the material is smooth by selectively dissolving the small convex parts on the surface. Compared with chemical polishing, the effect of cathode reaction can be eliminated, and the effect is better. The electrochemical polishing process is divided into two steps: 1. The macroscopic leveling solution diffuses to the electrolyte, and the material surface is reduced by geometric roughness, Ra> 1 microns. ⑵ Low light level anodic polarization, surface brightness increased, Ra< 1 microns.

Ultrasonic polishing

The workpiece is put into the abrasive suspension and placed in the ultrasonic field together, and the abrasive is ground and polished on the surface of the workpiece by the oscillation of the ultrasonic wave. The macro force of ultrasonic machining is small and will not cause deformation of the workpiece, but it is difficult to make and install the tooling. Ultrasonic processing can be combined with chemical or electrochemical methods. On the basis of solution corrosion and electrolysis, ultrasonic vibration is applied to stir the solution, so that the dissolved products on the surface of the workpiece are separated from the corrosion or electrolyte near the surface. The cavitation effect of ultrasonic wave in liquid can also inhibit the corrosion process, which is conducive to surface lighting

Fluid polishing

Fluid polishing depends on the high speed flowing liquid and the abrasive particles carried by the workpiece surface to achieve the purpose of polishing. Common methods are: abrasive jet processing, liquid jet processing, fluid power grinding. Hydrodynamic grinding is driven by hydraulic pressure, so that the liquid medium carrying abrasive particles reciprocates through the workpiece surface at high speed. The medium is mainly made of special compounds (polymeric substances) with good flow under low pressure and mixed with abrasives.The abrasivescan be made of silicon carbide powder

Magnetic grinding and polishing

Magnetic grinding and polishing is to use magnetic abrasives to form abrasive brushes under the action of magnetic field to grind the workpiece. This method has high processing efficiency, good quality, easy to control processing conditions and good working conditions. With suitable abrasives, the surface roughness can reach Ra0.1μm. 2 Mechanical polishing based on the method in plastic mold processing said that polishing and other industries required surface polishing is very different, strictly speaking, the polishing of the mold should be called mirror processing. It not only has high requirements for polishing itself, but also has high standards for surface smoothness, smoothness and geometric accuracy. Surface polishing is generally only required to obtain a bright surface. The standard of mirror finishing is divided into four levels: AO=Ra0.008μm, A1=Ra0.016μm, A3=Ra0.032μm, A4=Ra0.063μm, because it is difficult to accurately control the geometric accuracy of parts by electrolytic polishing, fluid polishing and other methods, and the surface quality of chemical polishing, ultrasonic polishing, magnetic polishing and other methods can not meet the requirements. Therefore, the mirror surface processing of precision mold is mainly mechanical polishing

The basic program

In order to obtain high quality polishing effect, the most important thing is to have high quality polishing tools and accessories such as whetstone, sandpaper and diamond grinding paste. The choice of polishing procedure depends on the surface condition after the early machining, such as machining, EDM, grinding and so on.