Rapid Prototyping Technologies Speed Up Product Development in the Home Appliance Industry

In today's fast-paced consumer market, getting new products to market quickly is key for home appliance manufacturers to stay competitive. While product quality and performance are still top priorities, the ability to significantly shorten development cycles through prototypage rapide gives companies a major advantage. By creating preliminary models in a fraction of the time using technologies like 3Impression D, Usinage CNC, and laser cutting, designers can iterate prototype designs more efficiently to optimize products before production. This allows errors to be found and addressed sooner, resulting in higher quality end products that better meet customer needs.

How Rapid Prototyping Benefits the Design Process

For home appliance designers, having physical prototypes early in the design process provides immense value. It allows them to test form, ajuster, and function before committing to more costly production methods. Engineers can simulate how users will interact with a product to identify any usability issues. Integrating hardware and software components into a prototype also enables functionality testing that isn't possible with CAD models alone. Receiving feedback from prototyping so early helps guide design refinements before significant resources are invested into tooling or manufacturing.

Prototyping for Improved Communication and Decision Making

Being able to produce prototype models on demand also facilitates better communication throughout the development process. Design teams can more easily collaborate across locations by sharing physical representations of concepts. Showcasing prototypes to clients, manufacturers, supply chain partners, and others also makes proposed designs much clearer compared to relying on drawings or renderings alone. This leads to better informed decision making that incorporates stakeholder perspectives earlier. Rapidly produced prototypes also allow exploring multiple design options simultaneously to determine the best path forward.

Cost and Time Savings Through Iterative Prototyping

For appliance manufacturers operating on tight deadlines, one of the biggest benefits of prototypage rapide technologies is the drastic reduction in the time required to produce prototypes. Whereas traditional prototyping methods like Usinage CNC plastic parts could take days or weeks, 3Impression D now delivers finished parts in hours. This enables quick iteration - designers can produce, test, and refine multiple prototypes in the time it previously took to make just one. All of this happens much earlier in the design cycle, giving teams more opportunities to identify and address issues proactively before product launch. This iterative process ultimately saves substantial development costs by avoiding expensive late-stage reworks.

Real-World Testing of Appliance Prototypes

Once prototypes are created, home appliance designers conduct rigorous testing to evaluate real-world performance. Prototypes are put through testing simulating the harsh day-to-day use expected over a product's lifespan. This includes examining durability and reliability under heavy and repeated use over time. Other testing analyzes how prototypes withstand various environmental conditions like temperature and humidity extremes. Ergonomic factors are thoroughly vetted as well to ensure safe, intuitive user experiences. Uncovering any design flaws or weaknesses early through extensive prototyping testing results in far more robust end products that last.

Rapid Prototyping Technologies Commonly Used in Appliance Design

A variety of rapid prototyping methods have become indispensable tools for home appliance engineers and industrial designers. 3D printing is one of the most versatile, enabling the creation of prototypes with intricate geometries or moving components not possible through traditional manufacturing. Multi-material 3D printing has further expanded possibilities. CNC machining remains valuable for prototypes made from durable materials like metals. Laser cutting also provides precision for sheet prototyping needs. Composite 3D printing now offers the ability to simulate finished product aesthetics and textures earlier as well. The combination of these advanced prototyping technologies delivers highly realistic appliance prototypes in a fraction of the time of old methods.

Améliorer le développement de produits, Innovation, and Time to Market

By fundamentally changing how prototypes are created, rapid prototyping opens entirely new possibilities for innovation in home appliance design. With iterative prototyping taking place much earlier, companies can evaluate many more design concepts to push boundaries. Rather than being confined by limitations of traditional manufacturing, designers are liberated to challenge conventions and explore truly new product forms, features, and interactions that better serve evolving customer needs. The compressed development cycles enabled through rapid prototyping also give appliance brands a significant competitive advantage in quickly delivering new, high-quality products to market ahead of competitors. Dans l'ensemble, rapid prototyping has transformed the home appliance industry by fueling continued product innovation at an accelerating pace. En conclusion, rapid prototyping technologies have become indispensible for home appliance product development teams focused on innovation, qualité, and accelerated time to market. By dramatically shortening the time required to produce highly realistic early-stage prototypes, designers gain valuable opportunities to rigorously test, refine, and validate new concepts earlier in the process when adjustments are least costly. This iterative prototyping approach has led to substantial savings in development time and costs across the industry, while driving continued advancement to deliver appliances that exceed customer expectations. With more advanced rapid prototyping methods on the horizon, its impact on the future of appliance design will only continue increasing.

Services professionnels de prototypage rapide

3Service d'impression D: Nous offrons de la haute qualité, solutions d'impression 3D rapides et abordables pour diverses industries et applications. Contactez-nous aujourd'hui pour un devis gratuit.

Precision CNC Machining service provides high-quality custom parts with tight tolerances and fast turnaround times. Contactez-nous pour un devis gratuit dès aujourd'hui.

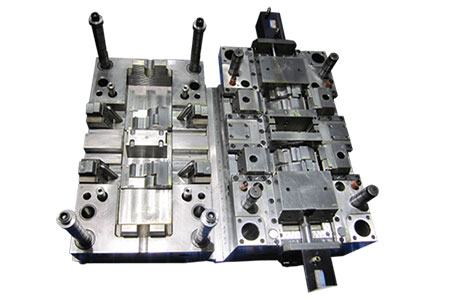

Service d'outillage rapide est un processus qui utilise l'impression 3D ou l'usinage CNC pour créer des moules ou des prototypes personnalisés en peu de temps. Il convient à la production en faible volume ou à des fins de test.

Plastic & Metal Batch Production

Plastique fabrication de moules est un processus de fabrication de produits en plastique qui implique la création d'un moule physique d'une forme conçue, l'utiliser pour fabriquer des produits en plastique ayant la forme et la taille souhaitées.

Moulage par injection plastique un service est un processus de production de pièces en plastique par injection de plastique fondu dans un moule. C'est rapide, précis et économique.

Métal service de moulage sous pression est un processus de création de pièces métalliques en injectant du métal en fusion dans un moule. Il offre une haute précision, durabilité et rentabilité pour diverses industries.

V1 Rapid Prototype aidant les gens à fabriquer des pièces et des produits en 2006. Nous offrons en termes de qualité et de service et dans le but de devenir le plus rapide et le plus fiable au monde.

À mesure que notre entreprise et notre clientèle se sont développées, notre gamme de services s'est également développée.. Nous sommes désormais l'une des seules entreprises au monde à proposer une gamme aussi vaste de solutions de prototypage et de fabrication sur mesure à faible volume, le tout sous un même toit.. Nos installations de prototypage rapide et de production de haute technologie comprennent Fraisage CNC, 3Impression D (SLA et SLS), coulée sous vide (uréthanes coulés), tôlerie et outillage rapide et moulage par injection ainsi que modélisme traditionnel et une gamme de techniques de finition.

laisser un message

Contact

Contactez-nous maintenant pour concrétiser votre idée, notre équipe professionnelle vous répondra dans 24 heures après réception de votre e-mail.

- E-mail: info@v-1.com

- Adresse de bureau: 2ème étage, NON. 10 Route de Lianhu, bourg de Chang'an, Ville de Dongguan, Province de Guangdong, Chine, 523850

- Adresse d'usine: N°38, Route d'Hexing, Shatou, bourg de Chang'an, Ville de Dongguan, Province de Guangdong, Chine, 523850