The application and advantages of Rapid Prototyping in automobile manufacturing

More and more modern advanced technologies have been applied in automotive manufacturing, which has accelerated the development of car manufacturing industry. The application of rapid manufacturing technology, efficiently shortens production cycle, saves production costs, and widely improves car quality.

With the continuous advancement of technology, the automobile manufacturing industry is also constantly introducing new ones to meet consumers' demands for higher quality, higher efficiency and more diversification. Among them, Rapid Prototyping technology is widely used in the automobile manufacturing industry. It is a rapid manufacturing technology that can help automakers manufacture auto parts and prototypes more quickly and accurately.

1. What is Rapid Prototyping

1.1 The concept of Rapid Prototyping

Prototypage rapide, also known as rapid prototyping technology, is a rapid manufacturing technology that can help automakers manufacture auto parts and prototypes more quickly and accurately.

1.2 Features of Rapid Prototyping

Rapid Prototyping has the characteristics of fast, precise and flexible. It can quickly manufacture auto parts and prototypes, avoiding the tedious and time-consuming traditional manufacturing process, while also allowing flexible adjustments and modifications as needed.

2. Application of Rapid Prototyping in Automobile Manufacturing

2.1 Manufacture of auto parts

Using Rapid Prototyping technology, automakers can manufacture vehicle parts more quickly and accurately. The traditional auto parts manufacturing process needs to go through multiple steps, such as design, fabrication, assembly, etc., but Rapid Prototyping can complete all manufacturing steps in one process, thereby improving production efficiency and reducing costs.

2.2 Fabrication of the prototype

Automakers build prototypes for testing when developing new models or parts. Traditional prototyping methods require a lot of time and human resources, but Rapid Prototyping technology can quickly manufacture prototypes, thereby improving R&D efficiency and reducing costs.

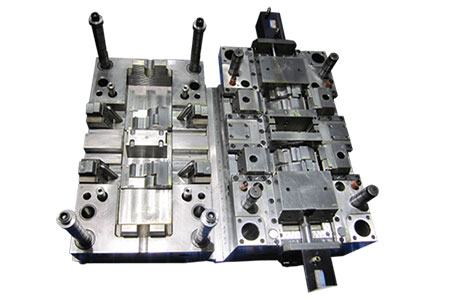

2.3 Manufacturing tools and fixtures

Automobile manufacturing requires a large number of tools and fixtures for manufacturing. Traditional manufacturing methods need to go through multiple steps, such as design, fabrication, testing, etc., but Rapid Prototyping can complete all manufacturing steps in one process, thereby improving production efficiency and reducing cost.

3. Advantages of Rapid Prototyping in automobile manufacturing

3.1 Improve production efficiency

Rapid Prototyping technology enables the rapid manufacture of automotive parts and prototypes, increasing productivity. Compared with traditional manufacturing methods, Rapid Prototyping can complete all manufacturing steps in a short time, thereby shortening the cycle of automobile manufacturing.

3.2 Improving Manufacturing Quality

Rapid Prototyping technology can help automakers create vehicle parts and prototypes more accurately, thereby improving manufacturing quality. Traditional manufacturing methods are prone to errors and defects, but Rapid Prototyping can manufacture auto parts and prototypes through digital models, avoiding errors and defects.

3.3 Cost reduction

Rapid Prototyping technology enables the rapid manufacture of automotive parts and prototypes, reducing manufacturing costs. Traditional manufacturing methods require a lot of time and human resources, but Rapid Prototyping can complete all manufacturing steps in a short time, thereby reducing manufacturing costs.

3.4 Improve innovation ability

Rapid Prototyping technology can help automakers innovate faster and more accurately, thereby improving innovation capabilities. Traditional manufacturing methods often require a lot of time and human resources, but Rapid Prototyping can quickly manufacture prototypes and parts, thereby helping automakers to develop and innovate more quickly.

4. The future development trend of Rapid Prototyping

As the automotive manufacturing industry continues to evolve, so will Rapid Prototyping technology. À l'avenir, Rapid Prototyping technology will become more popular, and automakers will apply this technology more widely, thereby improving the efficiency and quality of automobile manufacturing.

En même temps, Rapid Prototyping technology will be more digital and intelligent, and future automobile manufacturing will be more automated and intelligent. This will lead to a more efficient, accurate and reliable way of making cars, bringing better car products and experiences to consumers.

Summarize

Rapid Prototyping technology is a rapid manufacturing technique that helps automakers create vehicle parts and prototypes more quickly and accurately. It has the characteristics of fast, accurate and flexible, and is widely used in the automobile manufacturing industry. Using Rapid Prototyping technology, automakers can increase productivity, build quality, reduce costs, and increase innovation. With the continuous advancement of technology, the application prospect of Rapid Prototyping technology will be broader.

Services professionnels de prototypage rapide

3Service d'impression D: Nous offrons de la haute qualité, solutions d'impression 3D rapides et abordables pour diverses industries et applications. Contactez-nous aujourd'hui pour un devis gratuit.

Précision Usinage CNCLe service fournit des pièces personnalisées de haute qualité avec des tolérances serrées et des délais d'exécution rapides. Contactez-nous pour un devis gratuit dès aujourd'hui.

Service d'outillage rapide is a process that uses 3D printing or Usinage CNC to create custom molds or prototypes in a short time. Il convient à la production en faible volume ou à des fins de test.

Plastic & Metal Batch Production

Plastique fabrication de moules est un processus de fabrication de produits en plastique qui implique la création d'un moule physique d'une forme conçue, l'utiliser pour fabriquer des produits en plastique ayant la forme et la taille souhaitées.

Moulage par injection plastique un service est un processus de production de pièces en plastique par injection de plastique fondu dans un moule. C'est rapide, précis et économique.

Métal service de moulage sous pression est un processus de création de pièces métalliques en injectant du métal en fusion dans un moule. Il offre une haute précision, durabilité et rentabilité pour diverses industries.

V1 Rapid Prototype aidant les gens à fabriquer des pièces et des produits en 2006. Nous offrons en termes de qualité et de service et dans le but de devenir le plus rapide et le plus fiable au monde.

À mesure que notre entreprise et notre clientèle se sont développées, notre gamme de services s'est également développée.. Nous sommes désormais l'une des seules entreprises au monde à proposer une gamme aussi vaste de solutions de prototypage et de fabrication sur mesure à faible volume, le tout sous un même toit.. Nos installations de prototypage rapide et de production de haute technologie comprennent Fraisage CNC, 3Impression D (SLA et SLS), coulée sous vide (uréthanes coulés), tôlerie et outillage rapide et moulage par injection ainsi que modélisme traditionnel et une gamme de techniques de finition.

laisser un message

Contact

Contactez-nous maintenant pour concrétiser votre idée, notre équipe professionnelle vous répondra dans 24 heures après réception de votre e-mail.

- E-mail: info@v-1.com

- Adresse de bureau: 2ème étage, NON. 10 Route de Lianhu, bourg de Chang'an, Ville de Dongguan, Province de Guangdong, Chine, 523850

- Adresse d'usine: N°38, Route d'Hexing, Shatou, bourg de Chang'an, Ville de Dongguan, Province de Guangdong, Chine, 523850