Fused Deposition Modeling (FDM) is a widely used 3D printing process that involves melting and extruding a thermoplastic material to create a 3D object. This article explores the application of FDM in additive manufacturing, its advantages and disadvantages, and how it compares to other 3D printing processes.

Table of Content:

- Introduction to FDM in Additive Manufacturing

- FDM Process in 3D Printing

- FDM and SLS: A Comparison

- Advantages of FDM in Additive Manufacturing

- Examples of FDM Applications

- Best Use Cases for FDM

- Why is FDM Used?

- Disadvantages of FDM

- The Main Disadvantage of FDM

- Pros and Cons of FDM

- Conclusion: The Future of FDM in Additive Manufacturing

Introduction to FDM in Additive Manufacturing

Fused Deposition Modeling (FDM) is a widely used 3D printing process that has revolutionized the way we design and manufacture products. FDM works by melting and extruding a thermoplastic material through a nozzle, layer by layer, to create a 3D object. This article explores the advantages, disadvantages, and applications of FDM in additive manufacturing.

FDM Process in 3D Printing

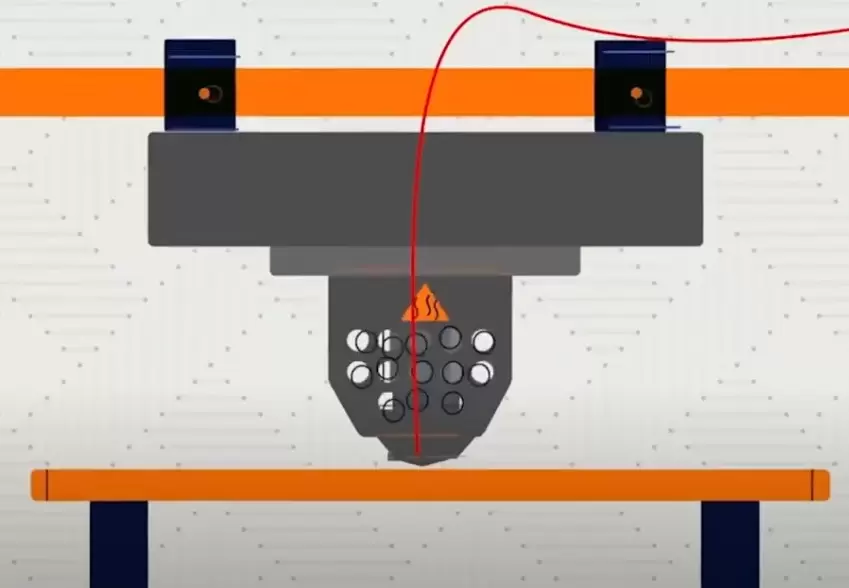

In the FDM process, a thermoplastic material is loaded into a 3D printer. The material is melted and extruded through a nozzle that moves in a precise pattern. The molten material is deposited layer by layer to create a 3D object. The FDM process is relatively fast and accurate, allowing for the creation of complex geometries.

FDM and SLS: A Comparison

Selective Laser Sintering (SLS) is another popular 3D printing process that uses a laser to selectively sinter a powdered material to create a 3D object. While both FDM and SLS are additive manufacturing processes, they differ in terms of the materials used, the types of objects that can be created, and the manufacturing speed and accuracy. FDM is generally considered to be faster and more accurate than SLS, but SLS allows for the creation of objects with intricate internal structures.

Advantages of FDM in Additive Manufacturing

FDM has several advantages in additive manufacturing, including its versatility, accuracy, and speed. FDM can be used with a wide range of materials, including thermoplastics, composites, and even metal. FDM is also highly accurate, allowing for the creation of objects with intricate geometries. Finally, FDM is relatively fast, allowing for the creation of complex objects in a relatively short amount of time.

Examples of FDM Applications

FDM has a wide range of applications in additive manufacturing, including the creation of prototypes, production parts, and even medical devices. For example, FDM is used to create prosthetic limbs, surgical tools, and dental implants. FDM can also be used in industries such as automotive, aerospace, and consumer goods to produce complex geometries and reduce the time and cost of product development.

Best Use Cases for FDM

FDM is best used for creating objects with simple to moderate complexity. It is ideal for producing prototypes, jigs and fixtures, and functional parts because of its accuracy and speed. FDM is also used in concept modeling due to its low cost and use of production-grade materials.

Why is FDM Used?

One of the main reasons FDM is used in additive manufacturing is its versatility. FDM can work with a wide range of materials, allowing for the creation of functional parts with different mechanical properties. FDM is also relatively fast and accurate, making it ideal for prototyping and low-volume production.

Disadvantages of FDM

Like any manufacturing process, FDM has its disadvantages. One of the biggest disadvantages is the layer-by-layer printing process, which can result in visible layer lines on the finished product. Another disadvantage is the limited range of materials that can be used with FDM, although this is improving as new materials are developed. FDM can also be more difficult to produce high-resolution parts than other processes.

The Main Disadvantage of FDM

The main disadvantage of FDM is the quality of the parts produced. Printed parts may have visible layer lines, and it can be difficult to produce parts with high precision or complex geometries. However, with the advent of new technology, FDM is becoming more accurate and capable of producing higher resolution parts.

Pros and Cons of FDM

Pros of FDM include its versatility, accuracy, and speed. FDM can be used with a wide range of materials, it is relatively fast and accurate, and it can be used to produce complex geometries. Cons of FDM include visible layer lines, difficulties in producing high-resolution parts, and a limited range of available materials.

Conclusion: The Future of FDM in Additive Manufacturing

Fused Deposition Modeling (FDM) is a widely used 3D printing process that has revolutionized the way we design and manufacture products. While FDM has some disadvantages, including visible layer lines and limited materials, it is still a versatile, fast, and accurate process that has a wide range of applications. With the continued advancements in technology, the future of FDM in additive manufacturing looks bright.

In conclusion, FDM is an important process in additive manufacturing, with several advantages and disadvantages. Its versatility, accuracy, and speed make it ideal for producing complex and functional parts, while its limitations in materials and resolution must be considered. As technology continues to evolve, FDM is likely to become more accurate, capable of producing higher resolution parts, and with an expanded range of available materials, making it a key player in the future of additive manufacturing.

tip: What is FDM in pharmaceutical industry?

In the pharmaceutical industry, Fused Deposition Modeling (FDM) is a 3D printing process that is used to create customized medical devices, dosage forms, and drug delivery systems. FDM allows for the creation of complex geometries, allowing for precise dosage and targeted delivery of medication. With FDM, pharmaceutical companies can create personalized drug products that are tailored to meet the specific needs of individual patients. This process can lead to reduced manufacturing time, cost savings, and improved patient outcomes.