Dive into the fascinating world of metal and hybrid systems in additive manufacturing. This comprehensive article sheds light on the innovative technologies and processes used in metal additive manufacturing, as well as the emerging field of hybrid systems. Explore the advantages, applications, and challenges of utilizing metal and hybrid systems in additive manufacturing and discover how they are revolutionizing the manufacturing industry.

Table of Contents:

- Introduction

- Understanding Metal Additive Manufacturing

- The Advancements in Metal Additive Manufacturing

- 3.1 Powder Bed Fusion (PBF) Technology

- 3.2 Directed Energy Deposition (DED) Technology

- Hybrid Systems: Blending Metal and Other Processes

- 4.1 The Concept of Hybrid Systems

- 4.2 Benefits of Hybrid Systems in Additive Manufacturing

- Applications of Metal and Hybrid Systems

- 5.1 Aerospace and Defense Industry

- 5.2 Medical and Dental Applications

- 5.3 Automotive and Tooling Sector

- Challenges in Metal and Hybrid Systems

- 6.1 Material Selection and Compatibility

- 6.2 Process Control and Optimization

- 6.3 Post-Processing and Finishing

- Conclusion

1. Introduction

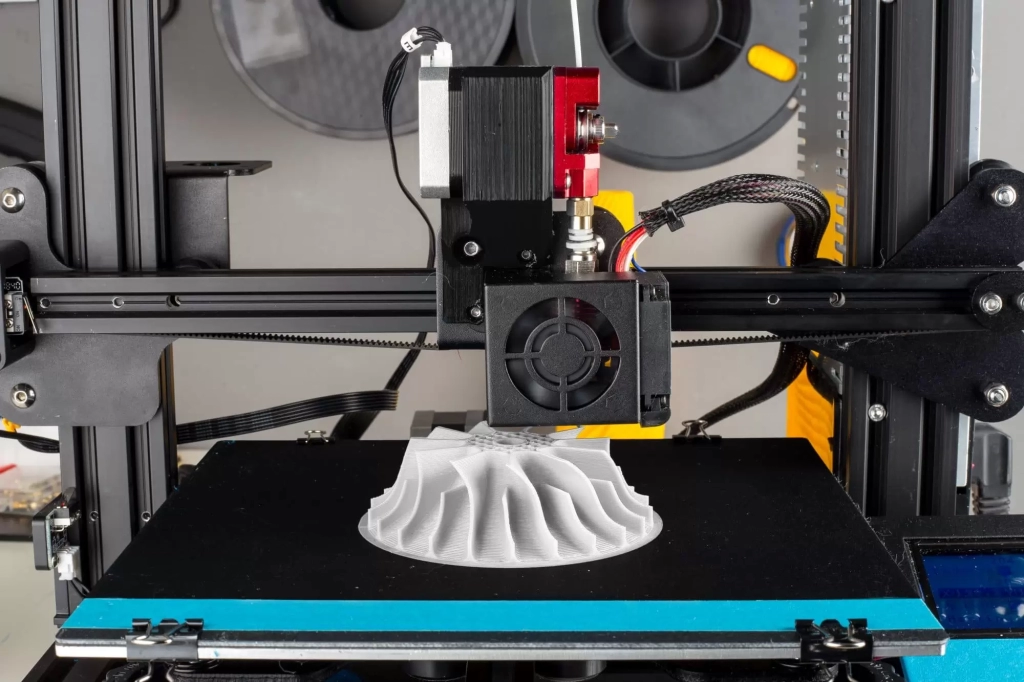

Additive manufacturing, also known as 3D printing, has witnessed remarkable advancements in recent years, particularly in the field of metal additive manufacturing. This article explores the exciting world of metal and hybrid systems in additive manufacturing. We delve into the principles, technologies, advantages, applications, and challenges associated with metal additive manufacturing and the emerging field of hybrid systems. Discover how these innovative processes are reshaping the manufacturing industry.

2. Understanding Metal Additive Manufacturing

Metal additive manufacturing is a subset of additive manufacturing that focuses on the production of metal components. It involves building three-dimensional objects layer by layer using various metal-based materials. Metal additive manufacturing offers unique advantages over traditional manufacturing techniques, including the ability to create complex geometries, reduce material waste, and customize parts for specific applications.

3. The Advancements in Metal Additive Manufacturing

Metal additive manufacturing has witnessed significant advancements in recent years, driven by continuous research and development efforts. Let's explore two key technologies commonly used in metal additive manufacturing:

3.1 Powder Bed Fusion (PBF) Technology

Powder Bed Fusion is a popular metal additive manufacturing technology that utilizes a high-energy heat source, such as a laser or electron beam, to selectively melt and fuse metal powders. This technology enables the production of intricate and precise metal parts with excellent mechanical properties. PBF techniques include Selective Laser Melting (SLM) and Electron Beam Melting (EBM), each offering its own set of advantages and applications.

3.2 Directed Energy Deposition (DED) Technology

Directed Energy Deposition involves depositing metal powder or wire onto a substrate and simultaneously melting it with a focused energy source, such as a laser or electron beam. DED technology allows for the creation of large-scale, near-net-shape parts or the repair and modification of existing components. DED offers versatility in terms of material selection, as it can process a wide range of metal alloys.

4. Hybrid Systems: Blending Metal and Other Processes

4.1 The Concept of Hybrid Systems

Hybrid systems in additive manufacturing combine metal additive manufacturing with other complementary processes to leverage their respective strengths. These hybrid approaches integrate multiple technologies, such as subtractive machining, post-processing, or additional material deposition methods, to optimize the production of complex metal parts. Hybrid systems offer flexibility, allowing manufacturers to tailor the manufacturing process to specific requirements.

4.2 Benefits of Hybrid Systems in Additive Manufacturing

Theintegration of hybrid systems in additive manufacturing brings several benefits to the manufacturing industry. Some key advantages include:

- Enhanced Design Freedom: Hybrid systems enable the combination of additive and subtractive processes, allowing for the production of intricate and complex geometries that may be challenging to achieve with a single technique.

- Improved Efficiency: By integrating different processes within a single system, hybrid approaches can streamline the manufacturing workflow, reducing production time and cost.

- Material Flexibility: Hybrid systems offer the ability to work with a variety of materials, including metals, polymers, ceramics, and composites. This flexibility opens up new possibilities for multi-material and multi-functional components.

- Surface Finish and Post-Processing: Hybrid systems allow for in-process finishing operations, reducing the need for separate post-processing steps. This results in improved surface quality, dimensional accuracy, and reduced lead times.

5. Applications of Metal and Hybrid Systems

Metal and hybrid systems in additive manufacturing find a wide range of applications across various industries. Let's explore a few notable examples:

5.1 Aerospace and Defense Industry

Metal additive manufacturing and hybrid systems have revolutionized the aerospace and defense sectors. They enable the production of lightweight yet strong components, such as turbine blades, engine parts, and structural elements. The ability to create complex internal geometries and consolidate multiple parts into a single component enhances performance while reducing weight.

5.2 Medical and Dental Applications

Metal additive manufacturing, combined with hybrid systems, has transformed the medical and dental fields. These technologies enable the production of patient-specific implants, prosthetics, and surgical instruments. The customization and accuracy offered by metal additive manufacturing contribute to improved patient outcomes and the creation of personalized medical solutions.

5.3 Automotive and Tooling Sector

The automotive and tooling industries benefit from the use of metal and hybrid systems in additive manufacturing. Complex parts with optimized geometries and lightweight designs can be produced, improving fuel efficiency and performance. Additionally, hybrid systems allow for the repair and modification of existing components, extending their lifespan and reducing waste.

6. Challenges in Metal and Hybrid Systems

Despite the numerous advantages, metal and hybrid systems in additive manufacturing face certain challenges that need to be addressed:

6.1 Material Selection and Compatibility

Selecting appropriate materials for metal additive manufacturing and ensuring their compatibility with the chosen process can be complex. The properties of the materials, including their melting and solidification behavior, thermal characteristics, and mechanical properties, must be carefully considered for successful outcomes.

6.2 Process Control and Optimization

Achieving consistent process control and optimization is essential in metal additive manufacturing and hybrid systems. Parameters such as laser power, scanning speed, layer thickness, and gas atmosphere must be carefully controlled to ensure part quality, dimensional accuracy, and material integrity.

6.3 Post-Processing and Finishing

Post-processing operations, such as heat treatment, surface finishing, and machining, are often required to achieve the desired final part characteristics. Developing efficient and effective post-processing techniques specific to metal additive manufacturing and hybrid systems is crucial to fully capitalize on their advantages.

7. Conclusion

Metal and hybrid systems in additive manufacturing have brought about significant advancements in the manufacturing industry. These technologies offer unique opportunities to produce complex metal parts with enhanced design freedom, material flexibility, and improved efficiency. The applications span across aerospace, medical, automotive, and tooling sectors, enabling the production of high-performance components. However, challenges such as material selection, process control, and post-processing need to be addressed to further enhance the capabilities and adoption of these systems. As technology continues to evolve, metal and hybrid systems will continue to shape the future of additive manufacturing, driving innovation and transforming manufacturing processes.

1. Metal System in Additive Manufacturing

The metal system in additive manufacturing refers to the use of metal materials to fabricate three-dimensional objects layer by layer. Unlike traditional manufacturing methods, where material is removed or shaped from a solid block, additive manufacturing builds components by adding material, thereby reducing waste and enabling more intricate designs. Metal additive manufacturing has gained immense popularity in industries such as aerospace, automotive, and medical, due to its ability to produce high-strength, complex, and lightweight parts.

2. Hybrid System in Additive Manufacturing

A hybrid system in additive manufacturing combines additive manufacturing processes with traditional subtractive techniques, merging the best of both worlds. This approach allows manufacturers to leverage the precision and complexity of additive manufacturing while also benefiting from the post-processing capabilities of traditional machining. By integrating the two processes, hybrid systems offer enhanced flexibility, cost-effectiveness, and improved overall part quality.

3. Most Commonly Used Technology in Hybrid Additive Manufacturing

Laser Metal Deposition (LMD) or Directed Energy Deposition (DED) is the most commonly used technology in hybrid additive manufacturing. In LMD/DED, a high-powered laser beam or electron beam is used to melt and fuse metal powders or wire feedstock onto a substrate, gradually building up the part layer by layer. This technique enables the repair, modification, and addition of material to existing parts, making it ideal for large-scale components and aerospace applications.

4. An Example of Hybrid Manufacturing Process

One of the remarkable examples of hybrid manufacturing is the repair and refurbishment of aircraft engine components. Aircraft engines endure extreme conditions, leading to wear and tear over time. With hybrid additive manufacturing, the damaged parts can be repaired or reinforced using LMD/DED technology. The process involves the following steps:

Step 1: Inspection and Preparation: The engine component is thoroughly inspected to identify areas that require repair or reinforcement. Digital scanning and modeling are used to create a 3D representation of the damaged part.

Step 2: Additive Manufacturing: Using LMD/DED, the damaged areas of the component are precisely repaired by depositing layers of compatible metal powders or wire feedstock. The additive manufacturing process rebuilds the part, ensuring structural integrity and dimensional accuracy.

Step 3: Post-Processing: After additive manufacturing, the part undergoes traditional machining to achieve the desired surface finish, tolerances, and final shape. This step ensures the component meets the required specifications.

Step 4: Quality Control: The repaired component undergoes rigorous testing and inspection to ensure it meets safety and quality standards. This step is critical to ensure the part's reliability and performance in demanding aerospace environments.

Metal and hybrid systems in additive manufacturing have revolutionized the way industries approach production and design. Metal additive manufacturing enables the creation of intricate, high-strength components, while hybrid systems combine additive and subtractive processes, providing greater flexibility and efficiency. As technology continues to evolve, we can expect even more exciting developments in the world of additive manufacturing, shaping the future of manufacturing across various sectors and propelling us towards a new era of innovation. Stay tuned to v1prototype.com for more updates on additive manufacturing and its groundbreaking applications.