Table of Contents:

- Introduction

- Materials Used in Sheet Metal Products

- Processes Involved in Sheet Metal Fabrication

- Applications of Sheet Metal Products

- Advancements in Sheet Metal Fabrication

- Benefits of Using Sheet Metal Products

- Challenges in Sheet Metal Fabrication

- Future of Sheet Metal Products

- Conclusion

-

1.Introduction

Sheet metal products are ubiquitous in modern manufacturing, found in everything from household appliances to airplanes. Sheet metal fabrication involves cutting, bending, forming, and welding metal sheets to create various products. In this article, we will explore the materials used in sheet metal fabrication, the processes involved, the applications of sheet metal products, advancements in the field, the benefits of using sheet metal products, the challenges in fabrication, and the future outlook.

-

2.Materials Used in Sheet Metal Products

Sheet metal fabrication can use various types of metals, including steel, aluminum, copper, brass, and titanium. Each metal has its own properties that make it suitable for different applications. For example, steel is strong and durable, making it ideal for structural applications, while aluminum is lightweight and corrosion-resistant, making it suitable for aircraft and automotive parts. The choice of material depends on the specific requirements of the product.

-

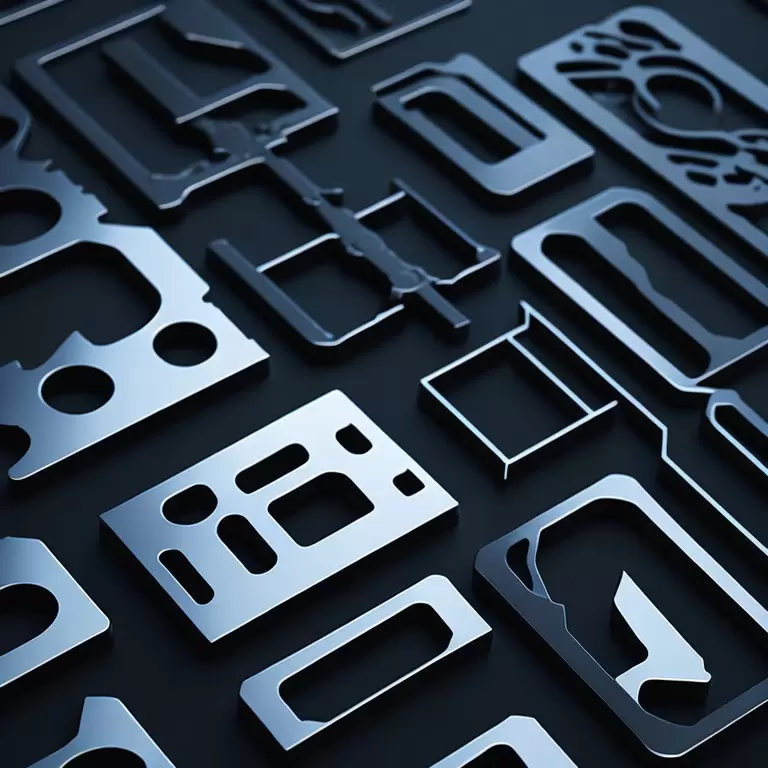

3.Processes Involved in Sheet Metal Fabrication

Sheet metal fabrication involves several processes, including cutting, bending, forming, punching, welding, and finishing. Cutting is the process of separating the sheet metal into the desired shape and size. Bending is used to create angles and curves in the metal, while forming shapes the metal into the desired shape. Punching is used to create holes in the metal, while welding is used to join two or more pieces of metal. Finishing involves removing any sharp edges or imperfections to create a smooth surface.

-

4.Applications of Sheet Metal Products

Sheet metal products are used in various industries, including:

- Automotive Industry: Sheet metal products are used to create vehicle body parts, such as doors, fenders, and hoods.

- Construction Industry: Sheet metal products are used in roofing, siding, and structural components of buildings.

- Aerospace Industry: Sheet metal products are used in the manufacture of aircraft components, such as wings, fuselage, and engine parts.

- Medical Industry: Sheet metal products are used to create surgical instruments and medical equipment.

- Consumer Goods Industry: Sheet metal products are used to create household appliances, such as refrigerators and washing machines.

-

5.Advancements in Sheet Metal Fabrication

Advancements in sheet metal fabrication have led to increased efficiency and accuracy in the manufacturing process. Computer-aided design (CAD) and computer numerical control (CNC) allow for precise control over the cutting and forming of sheet metal. Laser cutting technology has also improved precision and speed in cutting sheet metal. Robotic automation has made the manufacturing process faster and more efficient.

-

6.Benefits of Using Sheet Metal Products

Sheet metal products offer several benefits, including:

- Durability and strength: Sheet metal products are strong and durable, making them ideal for applications that require structural support.

- Cost-effective manufacturing: Sheet metal fabrication is a cost-effective method of manufacturing, particularly for large-scale production runs.

- Customizable designs: Sheet metal products can be customized to meet specific design requirements.

- Versatility in applications: Sheet metal products can be used in various industries and applications.

-

7.Challenges in Sheet Metal Fabrication

Sheet metal fabrication poses several challenges, including:

- Material wastage: The cutting and forming of sheet metal can result in significant material wastage, which can increase the cost of production.

- Quality control: Ensuring consistent quality in sheet metal products can be challenging, particularly for larger production runs.

- Precision and accuracy: Achieving precision and accuracy in sheet metal fabrication is crucial to ensure that the product meets design specifications.

-

8.Future of Sheet Metal Products

The future of sheet metal fabrication is likely to see continued advancements in materials and technologies. Environmental concerns have also led to a growing interest in sustainable solutions for sheet metal fabrication. Integration with Industry 4.0 technologies, such as artificial intelligence and the internet of things, is also likely to improve efficiency and reduce waste in the manufacturing process.

If you need about Sheet Metal services,You can click on the V1 Prototype website to find it:Custom Sheet Metal Parts And Assemblies In As Fast As 1 Day. Get An Online Quote Today.

-

9.Conclusion

Sheet metal products are an essential component of modern manufacturing, used in various industries and applications. The materials and processes involved in sheet metal fabrication have continued to evolve, leading to increased efficiency, accuracy, and sustainability. Despite the challenges posed by material wastage and quality control, sheet metal fabrication remains a cost-effective method of manufacturing. The future of sheet metal fabrication is likely to see continued advancements in materials, technology, and sustainability, as well as integration with Industry 4.0 technologies.