The application and advantages of Rapid Prototyping in automobile manufacturing

More and more modern advanced technologies have been applied in automotive manufacturing, which has accelerated the development of car manufacturing industry. The application of rapid manufacturing technology, efficiently shortens production cycle, saves production costs, and widely improves car quality.

With the continuous advancement of technology, the automobile manufacturing industry is also constantly introducing new ones to meet consumers’ demands for higher quality, higher efficiency and more diversification. Among them, Rapid Prototyping technology is widely used in the automobile manufacturing industry. It is a rapid manufacturing technology that can help automakers manufacture auto parts and prototypes more quickly and accurately.

1. What is Rapid Prototyping

1.1 The concept of Rapid Prototyping

Rapid Prototyping, also known as rapid prototyping technology, is a rapid manufacturing technology that can help automakers manufacture auto parts and prototypes more quickly and accurately.

1.2 Features of Rapid Prototyping

Rapid Prototyping has the characteristics of fast, precise and flexible. It can quickly manufacture auto parts and prototypes, avoiding the tedious and time-consuming traditional manufacturing process, while also allowing flexible adjustments and modifications as needed.

2. Application of Rapid Prototyping in Automobile Manufacturing

2.1 Manufacture of auto parts

Using Rapid Prototyping technology, automakers can manufacture vehicle parts more quickly and accurately. The traditional auto parts manufacturing process needs to go through multiple steps, such as design, manufacturing, assembly, etc., but Rapid Prototyping can complete all manufacturing steps in one process, thereby improving production efficiency and reducing costs.

2.2 Fabrication of the prototype

Automakers build prototypes for testing when developing new models or parts. Traditional prototyping methods require a lot of time and human resources, but Rapid Prototyping technology can quickly manufacture prototypes, thereby improving R&D efficiency and reducing costs.

2.3 Manufacturing tools and fixtures

Automobile manufacturing requires a large number of tools and fixtures for manufacturing. Traditional manufacturing methods need to go through multiple steps, such as design, manufacturing, testing, etc., but Rapid Prototyping can complete all manufacturing steps in one process, thereby improving production efficiency and reducing cost.

3. Advantages of Rapid Prototyping in automobile manufacturing

3.1 Improve production efficiency

Rapid Prototyping technology enables the rapid manufacture of automotive parts and prototypes, increasing productivity. Compared with traditional manufacturing methods, Rapid Prototyping can complete all manufacturing steps in a short time, thereby shortening the cycle of automobile manufacturing.

3.2 Improving Manufacturing Quality

Rapid Prototyping technology can help automakers create vehicle parts and prototypes more accurately, thereby improving manufacturing quality. Traditional manufacturing methods are prone to errors and defects, but Rapid Prototyping can manufacture auto parts and prototypes through digital models, avoiding errors and defects.

3.3 Cost reduction

Rapid Prototyping technology enables the rapid manufacture of automotive parts and prototypes, reducing manufacturing costs. Traditional manufacturing methods require a lot of time and human resources, but Rapid Prototyping can complete all manufacturing steps in a short time, thereby reducing manufacturing costs.

3.4 Improve innovation ability

Rapid Prototyping technology can help automakers innovate faster and more accurately, thereby improving innovation capabilities. Traditional manufacturing methods often require a lot of time and human resources, but Rapid Prototyping can quickly manufacture prototypes and parts, thereby helping automakers to develop and innovate more quickly.

4. The future development trend of Rapid Prototyping

As the automotive manufacturing industry continues to evolve, so will Rapid Prototyping technology. In the future, Rapid Prototyping technology will become more popular, and automakers will apply this technology more widely, thereby improving the efficiency and quality of automobile manufacturing.

At the same time, Rapid Prototyping technology will be more digital and intelligent, and future automobile manufacturing will be more automated and intelligent. This will lead to a more efficient, accurate and reliable way of making cars, bringing better car products and experiences to consumers.

Summarize

Rapid Prototyping technology is a rapid manufacturing technique that helps automakers create vehicle parts and prototypes more quickly and accurately. It has the characteristics of fast, accurate and flexible, and is widely used in the automobile manufacturing industry. Using Rapid Prototyping technology, automakers can increase productivity, build quality, reduce costs, and increase innovation. With the continuous advancement of technology, the application prospect of Rapid Prototyping technology will be broader.

Professional rapid prototyping services

3D Printing Service: We offer high-quality, fast and affordable 3D printing solutions for various industries and applications. Contact us today for a free quote.

Precision CNC Machining service provides high-quality custom parts with tight tolerances and fast turnaround times. Contact us for a free quote today.

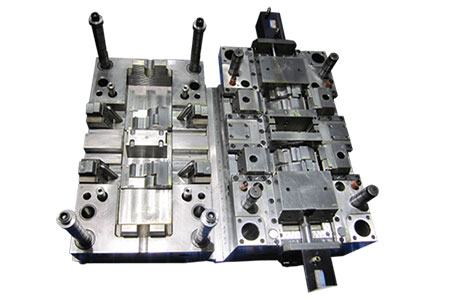

Rapid tooling service is a process that uses 3D printing or CNC machining to create custom molds or prototypes in a short time. It is suitable for low-volume production or testing purposes.

Plastic & Metal Batch Production

Plastic mold making is a process of manufacturing plastic products that involves creating a physical mold of a designed shape, using it to produce plastic products with the desired shape and size.

Plastic injection molding service is a process of producing plastic parts by injecting molten plastic into a mold. It is fast, precise and cost-effective.

Metal die casting service is a process of creating metal parts by injecting molten metal into a mold. It offers high precision, durability and cost-effectiveness for various industries.

V1 Rapid Prototype helping people make parts and products in 2006. We offer in terms of quality and service and with the aim to become the fastest and most dependable in the world.

As our company and customer base has grown so has our range of services. We are now one of the only companies in the world to offer such a massive range of prototyping and bespoke low volume manufacturing solutions all under one roof. Our high tech rapid prototyping and production facilities include CNC milling, 3D printing (SLA and SLS), vacuum casting (cast urethanes), sheet metal and rapid tooling and injection molding as well as traditional model making and a range of finishing techniques.

leave a message

Contact

Contact us now to bring your idea into reality, our professional team will respond you in 24 hours after we get your email.

- Email: [email protected]

- Office Address: 2nd Floor, NO. 10 Lianhu Road, Changan Town, Dongguan City, Guangdong Province, China, 523850

- Factory Address: No.38, Hexing Road, Shatou, Changan Town, Dongguan City, Guangdong Province, China, 523850