This guide explores the economic benefits of additive manufacturing, also known as 3D printing. You'll learn how to reduce costs in various areas, such as production, materials, and logistics. Discover innovative ways to optimize your manufacturing processes and increase efficiency. With this comprehensive guide, you'll navigate the economics of additive manufacturing and achieve cost-savings that drive your business forward.

I. Introduction to the Economics of Additive Manufacturing

A. What is Additive Manufacturing?

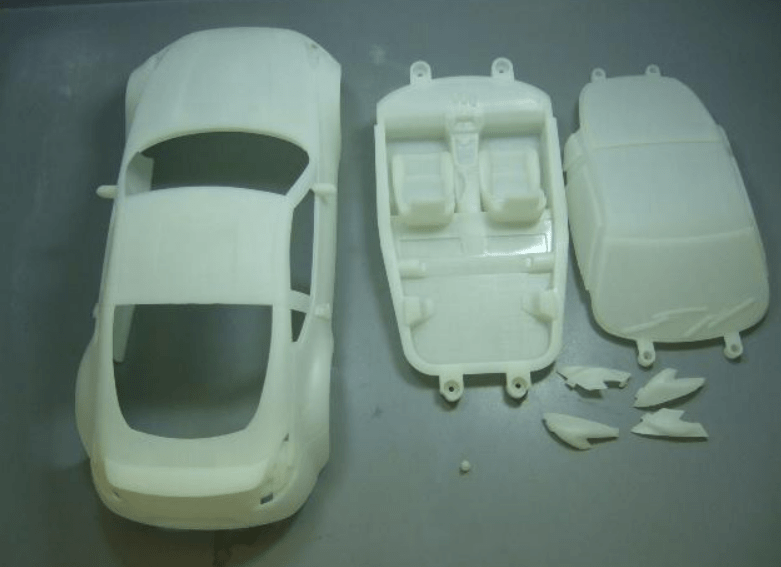

Additive Manufacturing (AM), commonly known as 3D printing, is a transformative technology that constructs objects layer by layer from digital models. Unlike subtractive manufacturing methods, which involve removing material from a larger piece, additive manufacturing builds up layers to form the final product.

B. The Role of 3D Printing in Manufacturing

3D printing plays a pivotal role in modern manufacturing by offering unparalleled flexibility, speed, and cost-effectiveness. It enables the creation of complex and customized designs with minimal waste, revolutionizing traditional production processes.

C. Cost-saving Opportunities with 3D Printing

The economic benefits of additive manufacturing extend beyond initial cost reductions. The technology allows for efficient prototyping, reduces material waste, and enables on-demand production, contributing to long-term cost savings.

II. Reducing Production Costs with 3D Printing

A. Rapid Prototyping and Tooling

3D printing accelerates product development through rapid prototyping, enabling designers to quickly iterate and test their concepts. Additionally, it facilitates the rapid production of tooling, reducing lead times and costs associated with traditional tooling methods.

B. Minimizing Waste with Material-efficient Printing

Traditional manufacturing often results in substantial material waste. 3D printing, on the other hand, employs an additive approach, utilizing only the necessary amount of material. This material efficiency minimizes waste, contributing to both cost savings and sustainability efforts.

C. High-volume Production with 3D Printing

While initially associated with prototyping, 3D printing has advanced to support high-volume production. With technologies like Selective Laser Sintering (SLS) and Stereolithography (SLA), businesses can produce large quantities of intricate parts with cost-effective and streamlined processes.

III. Saving on Materials with Additive Manufacturing

A. Material Selection and Cost-effectiveness

Choosing the right material is crucial for cost-effective additive manufacturing. By selecting materials based on their specific properties and cost-effectiveness, businesses can optimize the balance between performance and affordability.

B. Redesign for Less Material

3D printing allows for innovative design approaches that minimize material usage while maintaining structural integrity. Designing for additive manufacturing involves creating structures that are both lightweight and robust, further contributing to material cost savings.

C. Upcycling and Recycling with 3D Printing

Some 3D printing technologies support the use of recycled or upcycled materials. This not only reduces material costs but also aligns with sustainable practices by minimizing the environmental impact associated with traditional manufacturing processes.

IV. Optimizing Logistics with 3D Printing

A. On-demand Production and Localized Manufacturing

The ability to produce items on demand and locally is a significant advantage of 3D printing. This reduces the need for extensive warehousing and long-distance transportation, contributing to logistics cost savings.

B. Reducing Transportation Costs and Carbon Footprint

Traditional manufacturing often involves shipping products from centralized factories to various locations. With 3D printing, products can be manufactured closer to the point of consumption, minimizing transportation costs and reducing the carbon footprint associated with shipping.

C. Personalized Products and Just-in-Time Delivery

3D printing enables the production of personalized products with ease. This shift towards customization supports just-in-time manufacturing, reducing the need for large inventories and associated storage costs.

V. Case Studies in Cost-effective Additive Manufacturing

A. Innovative Applications in Healthcare

Explore how 3D printing has significantly reduced costs in the healthcare sector, from customized prosthetics to cost-effective patient-specific implants.

B. Revolutionary Designs in Architecture

Discover cost-effective solutions in architecture where 3D printing has transformed the construction industry, allowing for the creation of complex structures with reduced material and labor costs.

C. Groundbreaking Technologies in Manufacturing

Explore case studies showcasing how 3D printing technologies have revolutionized traditional manufacturing processes, reducing costs and improving efficiency.

D. Inspiring Creations in the Consumer Market

Delve into examples of cost-effective 3D printing applications in the consumer market, from customizable consumer goods to innovative and affordable creations.

VI. Conclusion

A. Summary of Key Learnings

In conclusion, navigating the economics of additive manufacturing offers numerous opportunities for cost savings across the production, materials, and logistics spectrum. The technology's ability to optimize processes, reduce waste, and support on-demand production positions it as a cornerstone for achieving economic efficiency in modern manufacturing.

B. Resources for Further Exploration

For those looking to delve deeper into the economics of additive manufacturing, various resources are available. Online forums, industry publications, and educational courses can provide valuable insights and knowledge to help businesses further optimize their operations and capitalize on the economic benefits of 3D printing.