Learn how coating and additive manufacturing can enhance the quality and functionality of your products. Boost your business with our expertise.

- Innovative Solutions for Coating and Additive Manufacturing

- How Coating Enhances Your Products’ Durability and Aesthetic Qualities

- Additive Manufacturing: A Game-Changer for Precision and Customization

- Our Coating Techniques and Materials

- Additive Manufacturing Technologies We Offer

- Experience the Benefits of Coating and Additive Manufacturing Today

Innovative Solutions for Coating and Additive Manufacturing

Are you looking for ways to improve the quality and functionality of your products? Additive manufacturing and advanced coating techniques can help take your products to the next level. In this post, we will discuss how coating and additive manufacturing can enhance your products, boost your business, and provide innovative solutions for business owners.

How Coating Enhances Your Products’ Durability and Aesthetic Qualities

Coating is a process of applying a layer of material over the surface of a substrate. This layer can enhance the durability and aesthetic qualities of the substrate, protecting it from moisture, corrosion, abrasion, or other environmental factors that can wear away or damage the surface. Whether you need to protect metal pipes, concrete floors, or plastic molds, coating can be a cost-effective and efficient way of prolonging the lifespan of your assets and improving their appearance.

At our company, we offer a range of coating techniques and materials to suit your needs. For example, we can use epoxy, polyurethane, acrylic, silicone, or other polymers to create a barrier or adhesive layer that bonds to your substrate and provides a smooth, seamless finish. We can also use high-temperature coatings, anti-fouling coatings, hydrophobic coatings, or other specialized coatings that are designed to withstand extreme conditions or specific applications.

Here are some examples of the benefits of coating:

- Improved corrosion resistance: Coating can prevent rust, oxidation, or pitting of metal surfaces by creating a barrier that blocks the exposure of the metal to the corrosive agents. This can extend the lifespan of your equipment, reduce maintenance costs, and avoid downtime due to equipment failure. Additionally, coating can make metal surfaces more hygienic and easier to clean, thus reducing the risk of contamination or infection in food processing, healthcare, or pharmaceutical industries.

- Enhanced durability: Coating can protect surfaces from wear and tear caused by friction, impact, or abrasion. By applying a thick or hard coating, you can increase the strength and toughness of your substrates, allowing them to withstand heavy loads, harsh environments, or repetitive use. This can be particularly beneficial in automotive, aerospace, or construction industries, where products need to withstand high stress conditions.

- Improved aesthetics: Coating can also improve the appearance and appeal of your products. By applying a decorative or functional coating, you can create a unique and attractive visual design that enhances the brand image, customer experience, or product differentiation. For example, you can use metallic, iridescent, or fluorescent pigments to create a shimmering effect or a color gradient. You can also use coatings that are resistant to UV light, weather, or chemicals, to maintain the color and gloss of your products over time.

Additive Manufacturing: A Game-Changer for Precision and Customization

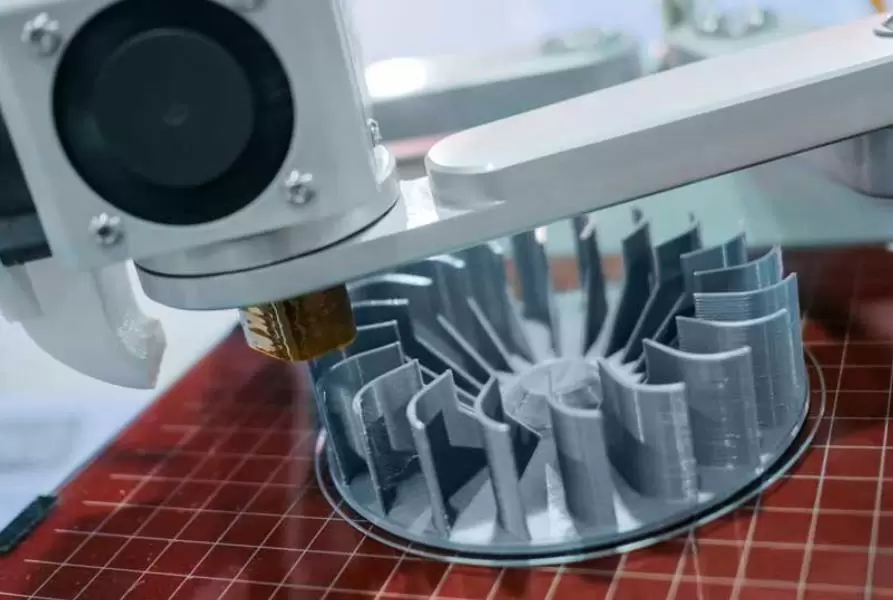

Additive manufacturing, also known as 3D printing, is a process of creating a three-dimensional object by adding layers of material, one on top of the other, until the desired shape is achieved. This technology allows for greater precision, customization, and complexity of designs, compared to traditional subtractive manufacturing methods. Additive manufacturing can also reduce production time, waste, and cost, by eliminating the need for tooling, molds, or assembly lines.

At our company, we use a range of additive manufacturing technologies to help our clients achieve their goals. We offer fused deposition modeling (FDM), stereolithography (SLA), digital light processing (DLP), and other 3D printing methods that can produce parts with different sizes, geometries, and materials. We can also offer post-processing services, such as sandblasting, painting, or electroplating, to create a smooth surface finish or a specific texture.

Here are some examples of the benefits of additive manufacturing:

- Increased design freedom: Additive manufacturing allows designers to create complex and intricate shapes that would be impossible or costly to produce with traditional methods. By layering materials in a controlled and precise way, additive manufacturing can produce parts with intricate details, curved surfaces, and internal structures that reduce weight, increase strength, or improve functionality.

- Reduced waste: Additive manufacturing can reduce waste by producing parts only when they are needed, without the need for bulk production or inventory. This can save storage space, material costs, and logistics expenses. Additionally, additive manufacturing can generate less scrap or defective parts, since the process is controlled digitally and can detect errors or deviations before they become significant.

- Customization: Additive manufacturing can customize parts to fit specific needs or preferences, without the need for manual or expensive adjustments. For example, additive manufacturing can produce prototypes, small batches, or unique designs, that cater to individual customers’ demands. This can enhance customer satisfaction, loyalty, and retention, by offering personalized and high-quality products.

Our Coating Techniques and Materials

At our company, we offer a range of coating techniques and materials that can be customized to your needs. Here are some examples:

- Epoxy coating: Epoxy coating is a two-part system that consists of resin and hardener. When mixed together, they chemically react and form a durable and strong material that can adhere to various substrates, such as concrete, metal, or wood. Epoxy coating can be used for many applications, such as flooring, pipes, tanks, or walls. It can provide a high gloss finish, resistant to chemicals, abrasion, and UV light.

- Polyurethane coating: Polyurethane coating is a versatile material that can be used for many applications, such as flooring, roofing, coating, or adhesives. Polyurethane coating can provide a protective layer that is resistant to water, chemicals, and abrasion. Additionally, it can provide a matte or glossy finish, depending on the desired appearance. Polyurethane coating can also be flexible or rigid, depending on the ratio of the components used.

- Silicone coating: Silicone coating is a non-toxic and heat-resistant material that can be used for many applications, such as electrical insulation, food packaging, or medical devices. Silicone coating can provide a waterproof and biocompatible layer that is resistant to temperature and UV light. Additionally, silicone coating can be transparent or colored, and has good adhesion to many substrates, such as glass, metal, or plastic.

- Our Additive Manufacturing Technologies

- At our company, we offer a range of additive manufacturing technologies that can be customized to your needs. Here are some examples:

- Fused deposition modeling (FDM): FDM is a process of creating 3D objects by extruding melted thermoplastic material from a nozzle onto a build platform. FDM can be used for rapid prototyping, small-batch production, or functional testing. The advantage of FDM is that it can use a variety of material options, ranging from flexible to rigid, depending on the application.

- Stereolithography (SLA): SLA is a process of creating 3D objects by using a laser to cure a liquid resin layer by layer. SLA can produce high-resolution details and smooth surfaces that are ideal for visual prototyping or jewelry making. The advantage of SLA is that it can create complex and intricate shapes with high accuracy.

- Digital light processing (DLP): DLP is a process of creating 3D objects by using a projector to solidify a liquid photopolymer material layer by layer. DLP can be used for dental, jewelry, or engineering applications that require high-resolution details and smooth surfaces. The advantage of DLP is that it can create parts quickly and with high precision.

- Experience the Benefits of Coating and Additive Manufacturing Today

- Whether you need to protect, enhance, or customize your products, coating and additive manufacturing can provide innovative solutions that cater to your needs. By combining the expertise of our team and the advanced technologies we use, we can help you achieve your goals, improve your products, and grow your business. Contact us today to learn more about our coating and additive manufacturing services and experience the benefits yourself!

At our coating and additive manufacturing company, we specialize in providing advanced coating techniques for your additive manufacturing needs. From anti-fouling coatings for marine parts to high-temperature coatings for aerospace components, we offer a range of options to protect your products from external factors that can cause wear and tear over time. Our additive manufacturing material coatings can provide your products with a durable finish and increase their longevity. We understand the importance of hydrophobic coatings in keeping your products dry and intact, and we offer customized ceramic or metallic coatings to meet your specific requirements. Our additive manufacturing coating process is reliable and effective, with precise coating thicknesses that ensure the highest quality of your products. We also offer corrosion-resistant coatings that can prevent rust or oxidation on metal parts and add to the product’s durability. Our coating powder is safe and easy to apply, and we can customize the coating for your unique needs. Through our expertise, we believe in the additive Manufacturing coating benefits that our coatings can offer, including customization and precision, while minimizing waste and costs. However, we also recognize the importance of transparency and acknowledge the additive manufacturing coating dis-advantages, such as potential defects that can occur during the process. At our company, we make it our priority to deliver the best results for our clients and address any concerns or issues that may arise in the coating additive manufacturing process.