Table of Contents:

- Introduction

- Types of Plastic Injection Molding Companies

- Choosing a Plastic Injection Molding Company

- The Benefits of Using a Plastic Injection Molding Company

- Conclusion

-

1. Introduction

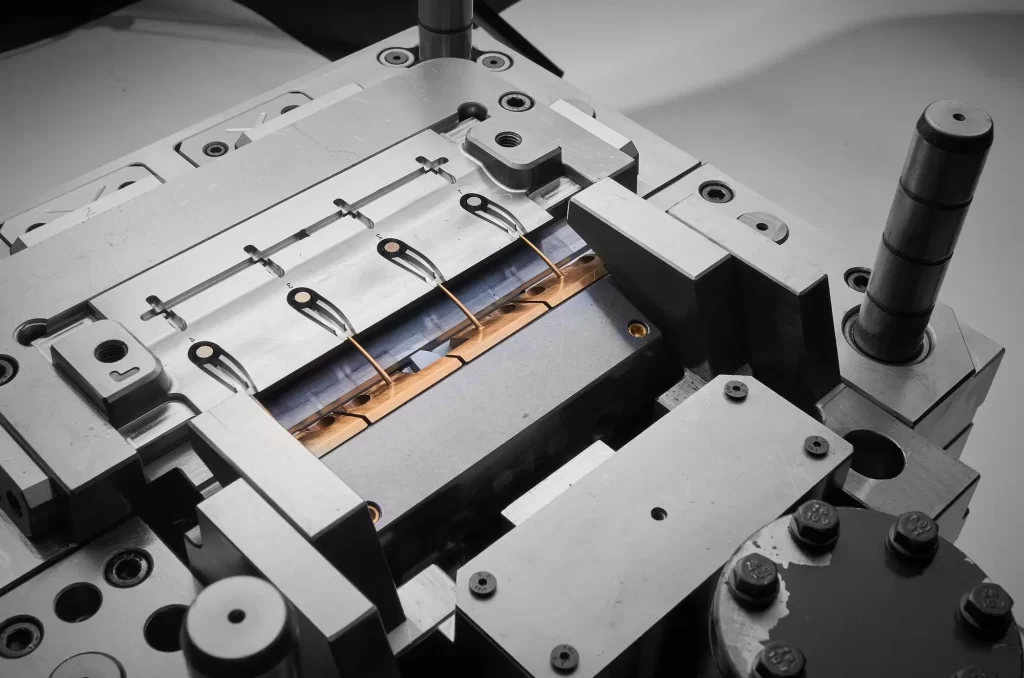

Plastic injection molding companies are a critical part of the manufacturing industry. These companies specialize in the production of plastic parts and products using the injection molding process. The process involves injecting molten plastic material into a mold, then cooling and solidifying it to create the desired shape. The benefits of working with a plastic injection molding company are numerous, including high-quality production, cost-effectiveness, and customization options. In this article, we will delve into what plastic injection molding companies are, the types of companies in existence, and how to choose the right one for your needs.

-

2. Types of Plastic Injection Molding Companies

There are three main types of plastic injection molding companies: custom injection molding companies, prototype injection molding companies, and large-scale injection molding companies.

Custom Injection Molding Companies:Custom injection molding companies focus on producing unique and innovative plastic parts and products based on customers’ specific requirements. These companies are perfect for businesses that require high quality, specialized parts or products in smaller quantities. They usually offer a range of custom services that include design, engineering, and prototyping services.

Prototype Injection Molding Companies:Prototype injection molding companies specialize in producing small quantities of parts or products using injection molding. These companies mainly focus on innovative product development and work with businesses that require functional prototypes to test designs before moving into large-scale production.

Large-Scale Injection Molding Companies:Large-scale injection molding companies specialize in high-volume production of plastic parts or products. These companies have a vast array of manufacturing equipment, enabling them to produce large quantities of high-quality parts and products.

-

3. Choosing a Plastic Injection Molding Company

Choosing the right plastic injection molding company requires careful consideration of several factors. Some things to consider include the company’s expertise and experience, production capabilities, quality controls, and costs. It is also crucial to consider the company’s reputation and customer service.

Comparison of different companies is also helpful when selecting a plastic injection molding company. Comparing various companies’ quality, processes, capacity, and pricing is crucial to ensure that you find the most excellent fit for your specific requirements.

If you need about Plastic Injection Molding Services,You can click on the V1 Prototype website to find it.

-

4. Benefits of Using a Plastic Injection Molding Company

Here are some benefits of using a plastic injection molding company:

- Cost-effective: Injection molding is an efficient and cost-effective process. With high-volume production, the cost of each unit decreases, making it more affordable.

- High accuracy and precision: Injection molding allows for precise and high accuracy in the production of plastic parts, ensuring that the final product meets exact specifications.

- Wide range of materials: Plastic injection molding companies use a wide variety of materials, including engineering-grade plastics, thermoplastics, and elastomers.

- Fast production time: Injection molding enables high-speed production, which means that large volumes of plastic parts can be produced within a short amount of time.

- Consistency and repeatability: Injection molding ensures consistent and repeatable parts, eliminating the need for post-production adjustments.

- Large-scale production: Injection molding is ideal for large-scale production, as it can produce hundreds of thousands of parts in a short amount of time.

- Design flexibility: Injection molding offers design flexibility, allowing for the creation of complex shapes and geometries that would be difficult to achieve with other manufacturing processes.

- Eco-friendly: The waste generated during plastic injection molding can be recycled and reused, making it an eco-friendly manufacturing process.

Another benefit of working with a plastic injection molding company is the customization options. Companies can customize parts or products to meet their specific requirements, including design, size, material, and color options.

-

5. Conclusion

Plastic injection molding companies play a critical role in the manufacturing industry, producing high-quality and cost-effective plastic parts and products. Three types of plastic injection molding companies exist, each specializing in different production quantities and requirements. Choosing the right company is crucial when it comes to receiving quality products at affordable prices. However, by considering quality, expertise, capacity, costs, and delivery lead-time, companies can find the right plastic injection molding company to meet their specific requirements.