3D printing hand board is to assist customers to improve the design, check the structure of the product, assembly is reasonable, the use of the product user feel, the appearance of the potential guests is how much appeal? So 3D printing hand board is a thing for industrial products, with the presentation of 3D printing, the first saved a lot of time for the development of the guests, the second for the guests to save a large amount of development costs.

In the early years, 3D printing hand board this occupation just presented when, is made by human hands little by little, the degree of mechanization is very low, that era of hand board natural use is also the most inconvenient and bad existence. When some CNC processing center began to use the general bias, hand board this profession has the first big leap forward, to 2000 years later, the market presented high-end SLA laser fast into the equipment.

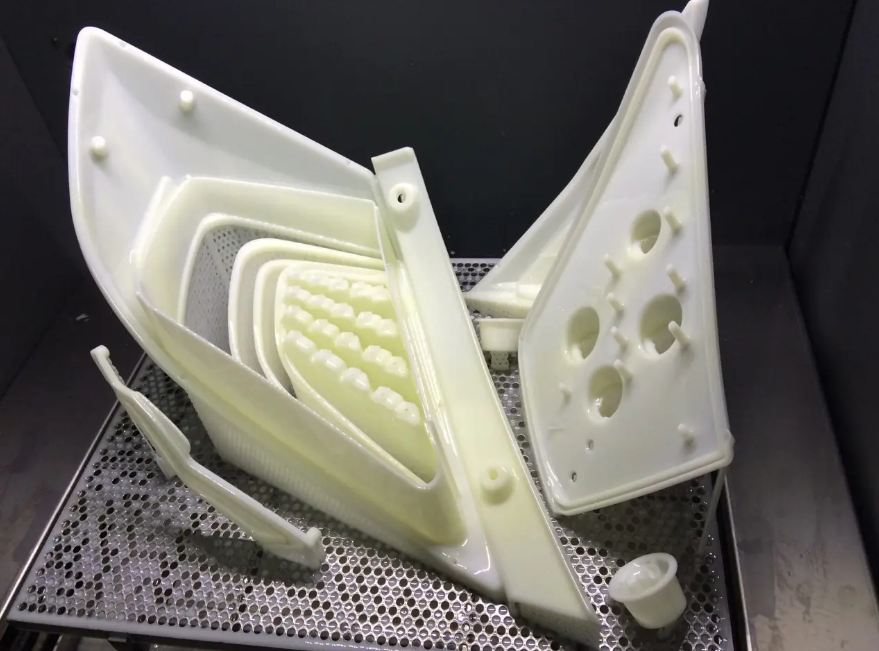

3D printing hand board occupation only really into high-end, SLA laser rapid prototyping equipment presented, greatly improving the accuracy of the hand board, but also greatly simplifies the hand board production difficulty, due to SLA laser rapid prototyping equipment special processing principle, any complex structure of the product is a one-time molding, only to have processed OK 3D data into the equipment, it will be like a tree growth principle of the same It grows out like a tree.

1) It only takes a few hours to dozens of hours to complete the manufacturing of one or several sets of prototype parts, and the product development cycle can be shortened by more than 40%;

2) No need to machine, turn or open the mold, can directly print prototype parts, greatly reducing the cost of product development;

3) The dimensional accuracy can meet the requirements of industrial grade assembly, the dimensional accuracy of plastic sample parts can reach ±0.1mm, and the dimensional accuracy of metal sample parts can reach ±20μm;

4) The plastic sample is made of high quality nylon 12 engineering plastic material, which has excellent performance of high strength, high toughness, wear resistance, corrosion resistance, temperature resistance, etc;

5) Rapid prototype can meet the requirements of a variety of harsh testing conditions, such as wind tunnel test (3000 rpm), water pressure and flow test (more than 10,000 times);

3D printing technology is still in continuous development, its advantages will become greater and greater, and create more and more miracles, 3D printing world is so wonderful, create what I want.

3D printing hand board in the actual application process, can be appropriate according to their own product needs to choose exactly what way to hand board model proofing, choose the right way, can reduce the cost of hand board and error rate of enterprises.

3D printing is a technology that has revolutionized the manufacturing industry. It is a process of creating physical objects from digital designs using various materials such as plastic, metal, or composites. 3D printing offers manufacturers the ability to produce complex designs and geometries that would have been impossible or too costly to create using traditional manufacturing methods. This article explores how choosing the right 3D printing method can help businesses reduce their manufacturing costs and error rates, and the advantages of 3D printing for businesses.

Does 3D printing reduce the cost of making things?

Overview

3D printing has revolutionized the way objects are designed and manufactured, making it possible to create objects with complex geometries and shapes. There are several ways in which 3D printing can help reduce the cost of making things, including:

- No Tooling Costs: Unlike traditional manufacturing methods, 3D printing does not involve the use of tools or dies (or any upfront investment in tooling). Instead, it involves the creation of a digital design that can be printed at any time.

- Reduced Material Waste: Traditional manufacturing methods involve a lot of material wastage during the production process. However, 3D printing reduces material waste since it is an additive process that involves only adding material where it is needed.

- Faster Time-to-Market: 3D printing allows for faster prototyping and production times. It allows businesses to quickly respond to customer demands and bring new products to market faster.

How could the 3D print cost could be reduced?

Choose The Right Printing Technology

Choosing the right printing technology is crucial to reducing the cost of 3D printing. Each printing technology has its own unique set of features, materials, and capabilities that make it suitable for different applications. Businesses that choose the right technology for the job can save both time and money.:

- Fused Filament Fabrication (FFF) or Fused Deposition Modeling (FDM): These technologies use thermoplastic filaments to print objects layer-by-layer. They are ideal for creating simple prototypes and models since they are relatively affordable and easy to use.

- Stereolithography (SLA): SLA is a fast and highly accurate printing technology that uses liquid resin to create objects. It is ideal for creating small, intricate designs with high precision and accuracy.

- Selective Laser Sintering (SLS): SLS is a 3D printing technology that uses lasers to melt and fuse powdered materials together. It is ideal for creating complex, high-precision parts and prototypes made from metals, plastics, and composites.

Optimize Your Design

Optimizing your design can help you reduce the cost of 3D printing significantly. By reducing your design's complexity and size, you can reduce the amount of material used and the print time for the object. Consider the following tips when optimizing your design:

- Minimize Material Usage: Reduce the amount of material used by designing smaller components, removing unnecessary features, or using less material-intensive infill patterns.

- Optimize the Orientation: Choose the optimal orientation for printing your design to prevent the need for support structures and reduce print time.

- Print with Multiple Objects: Print multiple objects at the same time to reduce the cost and print time per piece.

Choosing the right 3D printing method can reduce the company cost by optimizing the production process, minimizing the material waste, and enhancing the product quality. There are different types of 3D printing methods, such as fused deposition modeling (FDM), stereolithography (SLA), selective laser sintering (SLS), and direct metal laser sintering (DMLS). Each method has its own advantages and disadvantages, depending on the desired outcome, the complexity of the design, and the type of material used. Therefore, it is important to evaluate the factors that affect the choice of 3D printing method, such as cost, speed, accuracy, durability, and flexibility.