The application and advantages of Rapid Prototype in aerospace ship manufacturing

In order to meet the requirements of design verification in the aerospace field, prototype processing is an effective technical means. 3D printing technologyis a perfect embodiment of techniques and a direct and quick way for making prototypes to these special parts.

In addition, the processing of appearance model with equal proportion is a very good supplementary technique for public presentation and wind tunnel test. V1 Industrial has accumulated a wealth of experiences in assembly verification of cockpit and interior parts.

With the continuous development of science and technology, spaceships have become one of the important tools for human beings to explore the universe. In the design and manufacture of aerospace ships, using rapid prototype technology (rapid prototype) is an efficient method. This article will describe what rapid prototyping is, its application to spaceship manufacturing, and its benefits and challenges.

What is Rapid Prototyping?

Rapid prototyping is a manufacturing technique that uses computer-aided design (CAD) software and equipment such as 3D printers to quickly create a physical model of a product. This technology can help designers quickly validate their designs, saving time and cost while improving product quality and production efficiency.

Application of Rapid Prototyping Technology in Aerospace Ship

In aerospace ship manufacturing, rapid prototyping technology can be applied in the following aspects:

1. Manufacture of aerospace ship components

Rapid prototyping technology can manufacture parts of various shapes and structures, such as engine parts, mechanical parts, electronic components, etc. These parts can be tested and verified before actual use to ensure their quality and reliability.

2. Shell manufacturing of spaceships

The shell of a spaceship is an important component, which needs to have good airtightness and protection performance. Rapid prototyping enables the manufacture of spacecraft shells of different shapes and sizes, which are tested and validated to ensure their quality and reliability.

3. Manufacture of control systems for spaceships

The control system of a spaceship is a complex system that requires precise design and fabrication. Rapid prototyping technology can manufacture control system components in different shapes and sizes, and test and verify them to ensure their quality and reliability.

Advantages of Rapid Prototyping Technology

Rapid prototyping technology has the following advantages in aerospace ship manufacturing:

1. Save time and cost

Rapid prototyping technology can quickly manufacture solid models of spaceships, saving the time and cost required by traditional manufacturing methods.

2. Improve product quality and production efficiency

Rapid prototyping technology can help designers verify their designs before actual product manufacturing, improve product quality and production efficiency.

3. Improve design flexibility

Rapid prototyping technology can manufacture parts and components of various shapes and structures, which improves the flexibility and innovation of design, and enables designers to design and modify products more quickly.

To sum up, rapid prototyping technology is an efficient manufacturing technology in aerospace ship manufacturing. It can help designers verify designs, save time and cost, improve product quality and production efficiency, etc. However, it also needs to pay attention to the challenges of material limitations, precision limitations and manufacturing speed limitations. In aerospace ship manufacturing, the use of rapid prototyping technology needs to consider its advantages and disadvantages comprehensively to ensure its correct application in the design and manufacturing process.

Professional rapid prototyping services

3D Printing Service: We offer high-quality, fast and affordable 3D printing solutions for various industries and applications. Contact us today for a free quote.

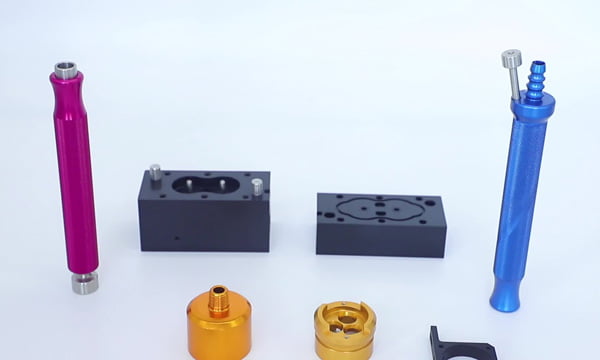

Precision CNC Machining service provides high-quality custom parts with tight tolerances and fast turnaround times. Contact us for a free quote today.

Rapid tooling service is a process that uses 3D printing or CNC machining to create custom molds or prototypes in a short time. It is suitable for low-volume production or testing purposes.

Plastic & Metal Batch Production

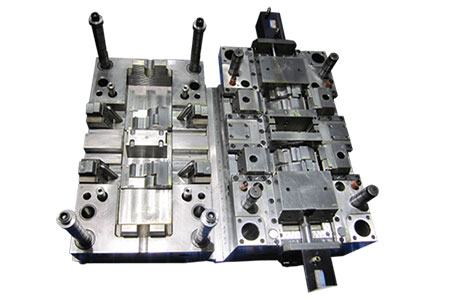

Plastic mold making is a process of manufacturing plastic products that involves creating a physical mold of a designed shape, using it to produce plastic products with the desired shape and size.

Plastic injection molding service is a process of producing plastic parts by injecting molten plastic into a mold. It is fast, precise and cost-effective.

Metal die casting service is a process of creating metal parts by injecting molten metal into a mold. It offers high precision, durability and cost-effectiveness for various industries.

V1 Rapid Prototype helping people make parts and products in 2006. We offer in terms of quality and service and with the aim to become the fastest and most dependable in the world.

As our company and customer base has grown so has our range of services. We are now one of the only companies in the world to offer such a massive range of prototyping and bespoke low volume manufacturing solutions all under one roof. Our high tech rapid prototyping and production facilities include CNC milling, 3D printing (SLA and SLS), vacuum casting (cast urethanes), sheet metal and rapid tooling and injection molding as well as traditional model making and a range of finishing techniques.

leave a message

Contact

Contact us now to bring your idea into reality, our professional team will respond you in 24 hours after we get your email.

- Email: [email protected]

- Office Address: 2nd Floor, NO. 10 Lianhu Road, Changan Town, Dongguan City, Guangdong Province, China, 523850

- Factory Address: No.38, Hexing Road, Shatou, Changan Town, Dongguan City, Guangdong Province, China, 523850