Photopolymerization is a common method in additive manufacturing, particularly in the production of 3D printed objects. In this article, we delve into the various aspects of the photopolymerization process in additive manufacturing, including its definition, steps, materials used, applications, and benefits. Additionally, we also touch on related topics such as polymerization, plastics, and the various types/stages of polymerization.

Table of Content:

I. Introduction

II. What is Photopolymerization Process?

III. Polymerization in Additive Manufacturing

IV. Photopolymerization in 3D Printing

V. Steps in Additive Manufacturing

VI. Methods of Polymerization

VII. Polymerization Process of Plastics

VIII. Materials Used in Photopolymerization

IX. Applications of Photopolymerization Process

X. Benefits of Photopolymerization Process

XI. Types of Additive Manufacturing

XII. Process of 3D Printing Additive Manufacturing

XIII. 3D Printing Process in Additive Manufacturing Process

XIV. Types and Stages of Polymerization

XV. Conclusion

I. Introduction

Additive manufacturing, more commonly known as 3D Printing, has greatly revolutionized the manufacturing industry by allowing for the production of complex and highly customized objects. One of the most common techniques used in additive manufacturing is photopolymerization. In this article, we will explore what the photopolymerization process entails, its stages, materials used, and the various benefits and applications of this technique.

II. What is Photopolymerization Process?

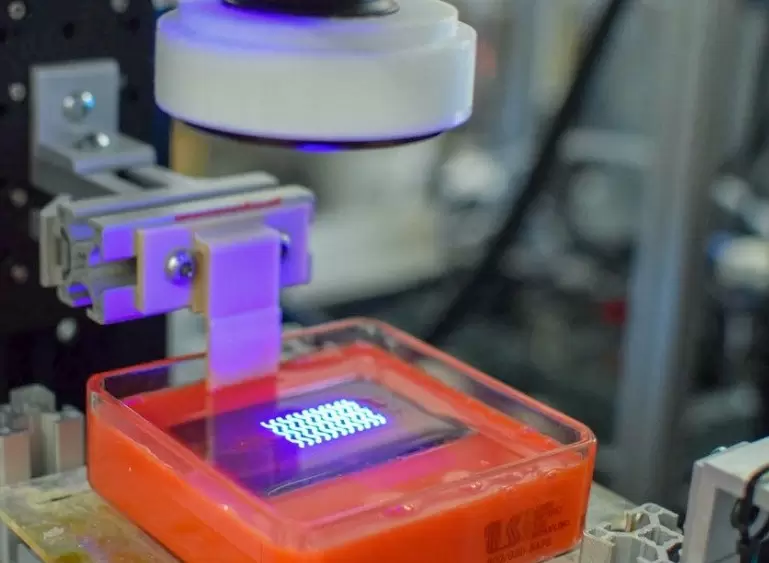

Photopolymerization is a process in which a liquid or semi-liquid material is exposed to a light source that causes it to solidify, or harden, into a three-dimensional object. This process is achieved through a chemical reaction between the material, called a photopolymer, and the light source, which typically emits ultraviolet (UV) light.

III. Polymerization in Additive Manufacturing

Additive manufacturing involves the layer-by-layer addition of materials to create a finished product. Polymerization is the process of joining small molecules (monomers) together to form large, complex molecules (polymers). In additive manufacturing, polymers are commonly used to create objects, and photopolymerization is one of the most popular polymerization methods.

IV. Photopolymerization in 3D Printing

Photopolymerization is frequently used in 3D printing, where a 3D printer can directly produce objects from a digital model. The process begins with the creation of a digital design or model, which is then uploaded to a 3D printer. The printer then creates the object by solidifying a photopolymer layer by layer until the final product is completed.

V. Steps in Additive Manufacturing

In general, additive manufacturing involves several stages. The first stage involves the creation of a 3D model, either through computer-aided design (CAD) or 3D scanning. This model is then sliced into layers, which are sent to the printer. The printer then produces the object layer by layer, often using one of several methods of polymerization, including photopolymerization.

VI. Methods of Polymerization

There are several methods of polymerization, including addition polymerization, condensation polymerization, and photopolymerization. In addition polymerization, monomers are joined together through double bonds to form a polymer chain. In condensation polymerization, monomers combine to eliminate a small molecule, typically water, to form a polymer. Photopolymerization, on the other hand, uses photoinitiators to create free radicals, which initiate the polymerization process.

VII. Polymerization Process of Plastics

Plastics are one of the most commonly used materials in additive manufacturing. The polymerization process of plastics involves the use of monomers and initiators. The monomers are heated to high temperatures, causing them to form reactive intermediates that can combine with other monomers to form a polymer. Initiators, on the other hand, are used to start the polymerization process by creating free radicals, which can initiate the polymerization reaction.

VIII. Materials Used in Photopolymerization

Various materials can be used in the photopolymerization process, including acrylates, epoxies, and vinyl esters, among others. These materials can be customized to produce a wide range of physical properties, such as strength, flexibility, and color. Additionally, the use of specific materials can help to optimize the photopolymerization process, such as the use of UV light-absorbing materials.

IX. Applications of Photopolymerization Process

The photopolymerization process has many applications, including in the production of dental impressions, prosthetics, and jewelry. It is also widely used in the creation of prototypes during the product design process. The use of photopolymerization in additive manufacturing has greatly reduced the costs and time required to produce small-scale and highly-customized parts that would have been difficult to produce using traditional manufacturing methods.

X. Benefits of Photopolymerization Process

One of the most significant benefits of the photopolymerization process is its high level of flexibility. Unlike other additive manufacturing methods, photopolymerization allows for the creation of very intricate objects with a high level of detail. It is also a fast process, enabling the production of finished parts within a relatively short period of time.

XI. Types of Additive Manufacturing

There are seven types of additive manufacturing processes:

- Material Extrusion

- Vat Photopolymerization

- Binder Jetting

- Sheet Lamination

- Powder Bed Fusion

- Directed Energy Deposition

- Hybrid Additive Manufacturing

Vat photopolymerization, also known as stereolithography (SLA), is the additive manufacturing process that involves photopolymerization.

XII. Process of 3D Printing Additive Manufacturing

The process of 3D printing additive manufacturing begins with the creation of a digital design or model using CAD software or 3D scanning. The model is then sliced into thin layers, and the 3D printer produces the object by adding the layers on top of one another. In the photopolymerization process, the printer produces the object by exposing a thin layer of liquid resin to a UV light source, causing the resin to solidify.

XIII. 3D Printing Process in Additive Manufacturing Process

Additive manufacturing, including 3D printing, has several advantages over traditional manufacturing methods. It allows flexibility in the design process, enabling the creation of complex geometries and internal structures that would have been impossible to produce using traditional methods. It also has a lower environmental impact, as it generates less waste and uses less energy and resources.

XIV. Types and Stages of Polymerization

There are two types of polymerization: addition polymerization and condensation polymerization. Addition polymerization involves the addition of monomers into a polymer chain. Condensation polymerization involves the formation of a polymer by joining two monomers, with the elimination of a small molecule, typically water. Polymerization has three stages: initiation, propagation, and termination.

XV. Conclusion

The photopolymerization process is a widely used method in additive manufacturing, particularly in the production of 3D printed objects. It involves the creation of a three-dimensional object by exposing a liquid or semi-liquid material to a UV light source, causing it to harden. This process has many advantages, including its flexibility, speed, and high level of detail. The photopolymerization process has numerous applications and is widely used across various industries, including healthcare, aerospace, and automotive.

- Photopolymerization Process:

Photopolymerization is a chemical process in which a liquid resin or a photopolymer is transformed into a solid, three-dimensional object when exposed to a specific wavelength of light, typically ultraviolet (UV) light. During photopolymerization, the resin undergoes a polymerization reaction, where individual monomer molecules link together to form a polymer network, resulting in the solidification of the material.

- Photopolymerization in 3D Printing:

In 3D printing, photopolymerization is a common technique used in a specific type of additive manufacturing called "Stereolithography" (SLA) or "Digital Light Processing" (DLP). In both SLA and DLP 3D printing, a vat of liquid photopolymer resin is exposed to a precise UV light source that selectively solidifies the resin layer by layer, following the instructions from a digital 3D model. As each layer is solidified, the build platform gradually moves upward, and the object is gradually formed from the bottom up.

- Steps in Additive Manufacturing Process:

The additive manufacturing process, including 3D printing, typically involves the following steps:

a. Design: Create a digital 3D model of the object to be printed using computer-aided design (CAD) software.

b. Slicing: The 3D model is sliced into thin horizontal layers using slicing software. This process generates the instructions (G-code) that the 3D printer will follow.

c. Preparation: The 3D printer is set up and calibrated, and the print bed or platform is prepared for printing.

d. Printing: The 3D printer begins the additive manufacturing process by depositing or solidifying material layer by layer according to the G-code instructions.

e. Cooling and Solidification: After each layer is deposited or solidified, it may undergo cooling or curing to ensure it maintains its shape and integrity.

f. Layer-by-Layer Build: The printer continues to add subsequent layers on top of each other until the entire object is completed.

g. Post-Processing: Depending on the 3D printing technology used, post-processing steps like cleaning, support removal, and curing may be required to finalize the printed object.

h. Quality Control: The finished 3D printed object undergoes inspection and quality control to ensure it meets the required specifications and standards.

- Technique that Uses Photopolymerization Process for 3D Printing:

The technique that uses the photopolymerization process for 3D printing is "Stereolithography" (SLA) and "Digital Light Processing" (DLP). Both SLA and DLP 3D printing rely on the solidification of liquid photopolymer resin using UV light to build the object layer by layer. These technologies are commonly used in various industries due to their ability to create highly detailed and accurate 3D printed parts.