Table of Contents:

- Introduction

- Advantages of CNC Prototyping in China

- Choosing a CNC Prototyping Company in China

- CNC Prototyping Process in China

- Applications of CNC Prototyping in China

- Challenges and Risks in CNC Prototyping in China

- Conclusion

-

1.Introduction

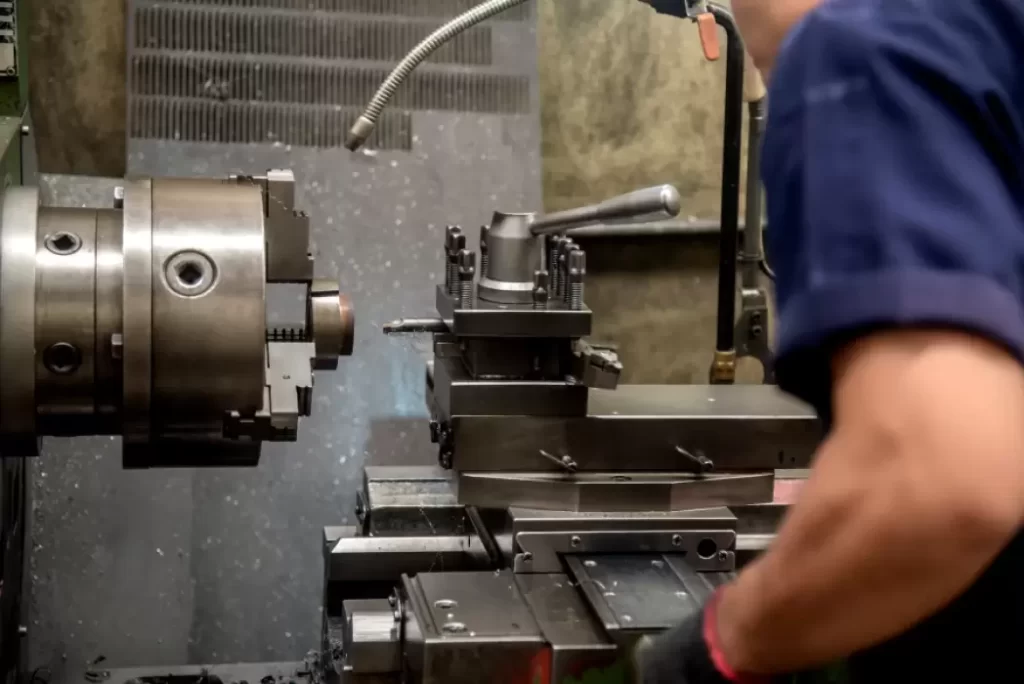

CNC prototyping refers to the process of creating a physical model or an actual product from a digital design using computer-controlled machines. It is commonly used in the manufacturing industry to quickly and accurately produce small-scale parts, components or complete products. Prototyping is an essential step in the product development process as it allows designers and engineers to test the feasibility, functionality, and appearance of a design before it is mass-produced.

-

2.Advantages of CNC Prototyping in China

CNC prototyping in China has numerous advantages over traditional manufacturing methods. This section will discuss the main advantages of CNC prototyping in China:

Cost-Effective Manufacturing:China’s low labor costs, production infrastructure, and established supply chains result in low-cost, high-quality parts and product production. CNC technology in China offers high accuracy and repeatability, which translates to cost savings for businesses producing parts and components.

High-Quality Outputs:CNC machines in China are equipped with advanced technology that can produce precision parts with high accuracy and consistency. This results in high-quality outputs that meet the specifications of customers.

Quick Turnaround Time:CNC prototyping in China has a quick turnaround compared to manual production methods. The automation of the process and advanced software used in CNC prototyping allows for the rapid production of complex components.

Access to Advanced Technology:China invests heavily in technology infrastructure, research, and development to enhance production capability. As a result, CNC machine tools used in China are advanced, and the software used for prototyping is cutting-edge, providing fast lead times for parts production.

-

3.Choosing a CNC Prototyping Company in China

Choosing the right CNC prototyping company in China is essential to ensure high-quality outputs and a reliable partnership. This section will discuss some of the factors to consider when choosing a CNC prototyping company in China and provide an overview of some of the popular CNC prototyping companies in China.

Factors to Consider:

- Expertise and Experience - Choose a company with vast experience in CNC prototyping, backed by a team of specialized engineers and designers, and with an excellent understanding of your specific requirements and challenges.

- Quality of Work - Look for a company that ensures high-quality outputs by offering quality checks and control procedures throughout the prototyping process.

- Delivery Time - Ensure the company can deliver your product within a reasonable timeframe, providing manufacturing and delivery deadlines that align with your project schedule.

- Customer Service - Look for a company that provides excellent customer service, prompt communication, and personalized support tailored to your project’s specific requirements.

- Technology - Choose a company with access to advanced technology and machinery capable of producing high-precision components with various materials.

Popular CNC Prototyping Companies in China:

- Baima Technology

- CreateBot

- Fast CNC Prototype

- Junying Die Casting Corporation

- Top-Prototyping Co., Ltd.

-

4.CNC Prototyping Process in China

The CNC prototyping process in China typically involves four main steps: design, programming, testing, and manufacturing. This section provides an overview of the steps involved in CNC prototyping in China, the technologies used, and the materials available for prototyping.

Steps Involved in CNC Prototyping:

- Design - The initial step involves creating a design using 3D modeling software that generates a 3D digital model.

- Programming - The design model is then imported into a CAM system (Computer-Aided Manufacturing) that converts it into a machine-readable format that can be used by a CNC machine.

- Testing - After the program’s creation, the CNC machine operator performs a series of tests to ensure that the created tool path is correct and that the machine is properly configured.

- Manufacturing - Once the pilot runs demonstrate that the design meets the required specifications, full-scale manufacturing can begin.

Technologies Used:

CNC machining centers in China use various technologies, including:

- Milling and Turning - The machine tilts parts under its control and turns the cutting tool under computer direction to cut parts from various angles.

- Laser Cutting - This technology is used in fabricating sheet materials and complex parts by careful material removal with a high-power laser.

Materials Available for Prototyping:

CNC prototyping in China uses many different materials that can be used to create a wide range of prototypes. Some common materials used in CNC prototyping include:

- Metals - aluminum, brass, copper, steel, and many others

- Plastics – ABS, POM, Nylon, PMMA, PEEK, and many others

- Wood and Composites – MDF, Polyurethane, and many others.

-

5.Applications of CNC Prototyping in China

CNC prototyping in China has various applications across the automotive, aerospace, medical, and consumer goods industries. This section provides an overview of the applications of CNC prototyping in China.

Automotive Industry:CNC prototyping in China is widely used in the automotive industry to produce parts to precise specifications. CNC machines can manufacture a range of automotive parts, such as engine components, brake systems, gearbox and transmission, and structural parts.

Aerospace Industry:CNC prototyping is a critical component of the aerospace manufacturing process in China. It is used to produce flight-critical components due to its ability to maintain tight tolerance and high precision. Components produced include parts for planes, rockets, satellites, and drones.

Medical Industry:CNC prototyping in China is used in the medical sector to produce parts that are critical to surgical procedures. CNC machines can produce high-precision medical equipment and devices, including surgical tools, endoscopes, and implantable devices.

Consumer Goods Industry:CNC prototyping in China finds application in the production of consumer goods such as electronics, toys, and household goods. CNC prototyping allows businesses to quickly produce high-quality, low-cost prototypes in small batches or customize products without compromising quality.

If you need about CNC Prototyping Services,You can click on the V1 Prototype website to find it.

-

6.Challenges and Risks in CNC Prototyping in China

While CNC prototyping in China offers businesses various benefits, there are also some challenges and risks that companies need to be aware of when using these services. This section provides an overview of some of the key challenges and risks of CNC prototyping in China.

Intellectual Property Concerns:Intellectual property (IP) theft is a significant risk for businesses that use CNC prototyping services in China. Although the government in China has made great strides to protect IP, some unethical manufacturers still counterfeit products and steal trade secrets. To mitigate this risk, companies should diligently research potential Chinese prototyping partners and seek legal counsel when required.

Supply Chain Disruptions:Disruptions to the supply chain are another potential challenge when using CNC prototyping in China. Unforeseen events such as factory shutdowns, natural disasters or political instability can cause significant delays if manufacturers aren’t adequately prepared. To counter this, businesses must ensure contracts with their Chinese CNC prototyping partner include clear contingency provisions.

Quality Control Issues:Ensuring the quality of parts produced in China can be a significant concern, mainly if the manufacturer is only discovered through web searches or referral networks. Some Chinese manufacturers may cut corners to reduce costs or use non-conforming materials in manufacturing. To address this, companies should conduct due diligence, engage independent third-party inspection firms and or use manufacturers with appropriate certifications and credentials.

-

7.Conclusion

In conclusion, CNC prototyping in China offers businesses many benefits, including cost-effectiveness, high-quality outputs, quick turnaround time, and access to advanced technology. However, companies must also be aware of the challenges and risks associated with using CNC prototyping in China, including IP concerns, supply chain disruptions, and quality control issues.

Despite these concerns, CNC prototyping in China remains a popular option for many businesses. With access to advanced machinery and technology, manufacturers in China can offer businesses cost-effective, high-quality manufacturing solutions for a wide range of applications. Additionally, the Chinese government is making great strides towards IP protection, and this bodes well for the future of CNC prototyping in China.

Future Trends in CNC Prototyping:

In the future, we can expect to see advanced materials, intelligent automation, and new manufacturing technologies converge to create more efficient and cost-effective CNC prototyping solutions in China. There will likely be the integration of AI-powered systems to improve efficiency and accuracy, leading to even better-quality outputs. There may also be growing pressure on CNC prototyping manufacturers to make their operations more sustainable and environmentally friendly.

In summary, CNC prototyping is an essential step in the product development process in China, and businesses can benefit significantly from a partnership with a reputable manufacturer. In the future, we can anticipate that CNC prototyping solutions in China will continue to evolve and improve, meeting the diverse needs of businesses across numerous industries.