Table of Contents:

- Introduction

- Cost Factors of Injection Molding Machine

- Breakdown of Injection Molding Machine Costs

- Cost Savings and ROI Calculation

- Tips for Reducing Injection Molding Machine Costs

- Conclusion

-

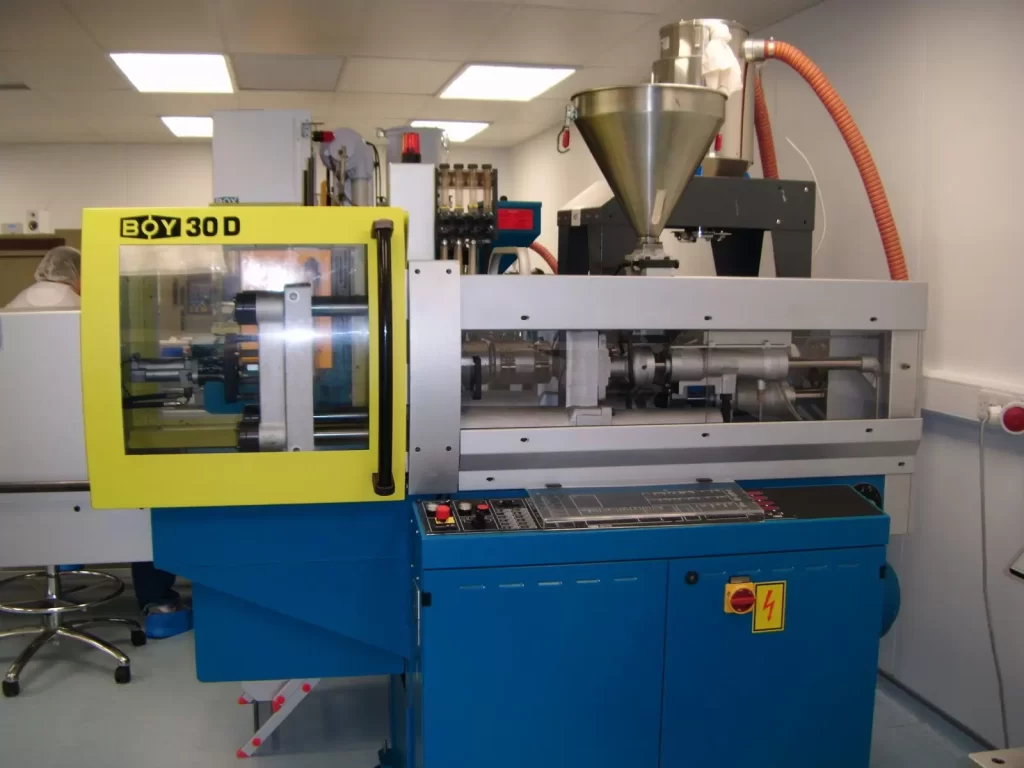

1. Introduction

A quality injection molding machine is critical to the success of a manufacturing operation. These machines enable the production of high-quality and durable parts, while also reducing the overall production time and costs. However, understanding the factors that influence the cost of these machines can be challenging. In this article, we will delve into the key factors that impact injection molding machine cost and offer insight on how to reduce those costs.

-

2.Cost Factors of Injection Molding Machine

Several factors influence the cost of injection molding machines. These include:

- Machine Size and Tonnage

The size and tonnage of the injection molding machine is a key determining factor of the machine’s cost. Generally, a higher tonnage machine is more expensive, and larger machines will cost more than smaller ones. - Machine Complexity and Features

The level of machine complexity and added features, such as automation capabilities or advanced software, will affect the cost of the machine. More complex machines will be more expensive. - Material and Color Capabilities

Injection molding machines that can process a wider range of materials or produce parts in multiple colors, require extra equipment that can increase the machine’s cost. - Automation and Auxiliary Equipment

Automated injection molding machines and auxiliary equipment like conveyors, material feeders, and molds can improve process efficiency, but can also drive up the overall cost of the machine. - Service and Support

Available service and support options will affect the overall cost of the injection molding machine. Comprehensive maintenance and support services may increase the machine’s upfront cost but may reduce maintenance costs over time.

-

3. Breakdown of Injection Molding Machine Costs

A. Initial Investment

The initial investment cost of an injection molding machine comprises the purchase price of the machine, auxiliary equipment, molds, and tooling expenses. These costs will differ based on the size, complexity, and added features of the machine.

B. Operational Costs

Injection molding machines have ongoing operational costs associated with them. These costs include raw materials, labor, energy consumption, and machine maintenance and repair costs.

- Material Costs

The cost of the raw materials, which include plastic pellets and colorants, is a significant part of the overall operational cost of injection molding machines. - Labor Costs

Operators or technicians are needed to run the machine, remove the parts, and handle any part finishing tasks. Labor costs can account for a significant portion of production expenses. - Energy Usage Costs

Injection molding machines require a significant amount of energy to melt the plastic pellets and operate the machine. The energy expenses can add up quickly, especially for larger machines. - Maintenance and Repair Costs

To ensure consistent operation and prevent breakdowns, injection molding machines require regular maintenance and repairs, which can become costly if not well-managed.

-

4. Cost Savings and ROI Calculation

Companies that are looking to invest in injection molding machines can identify cost-saving opportunities by implementing strategies to reduce the initial investment cost and operational costs associated with these machines. Cost-savings opportunities can include improving production efficiency, reducing waste, and selecting the right material for the job.

An ROI calculation can help identify the financial benefits of investing in an injection molding machine. The calculation considers factors such as production volume, material savings, and reduced labor costs. By identifying cost-saving measures and conducting an ROI calculation, a business can make an informed decision regarding the investment in an injection molding machine.

-

5. Tips for Reducing Injection Molding Machine Costs

Several tips can be helpful in reducing the overall cost of injection molding machines.

- Regular Maintenance and Repair

With proper maintenance and repair, a business can keep its injection molding machines in top condition, improving machine efficiency while reducing operational and repair costs. - Smart Material Selection

Choosing the appropriate material for the application and the machine’s capability can help reduce waste, maintenance, and repair costs. By selecting the material best suited for the job, businesses can avoid costly repairs and wasted material. - Efficient Production Planning and Optimization

Efficient production planning and optimization can help in reducing operational costs by minimizing material waste and increasing machine efficiency. Evaluating production processes from start to finish can help identify bottlenecks and areas for improvement in the production cycle.

-

6. Conclusion

In conclusion, investing in an injection molding machine is a significant undertaking. Understanding the factors that influence the cost of these machines and implementing strategies to reduce the initial investment cost and operational costs can help a business realize the benefits of this investment. Proper maintenance, repair, and material selection practices, in addition to efficient production planning and optimization, are key strategies to reduce the overall injection molding machine cost. By taking these measures, a business can benefit from a secure and efficient production process while minimizing production costs over time.

If you need about Injection Molding Services,You can click on the V1 Prototype website to find it.