Introduction

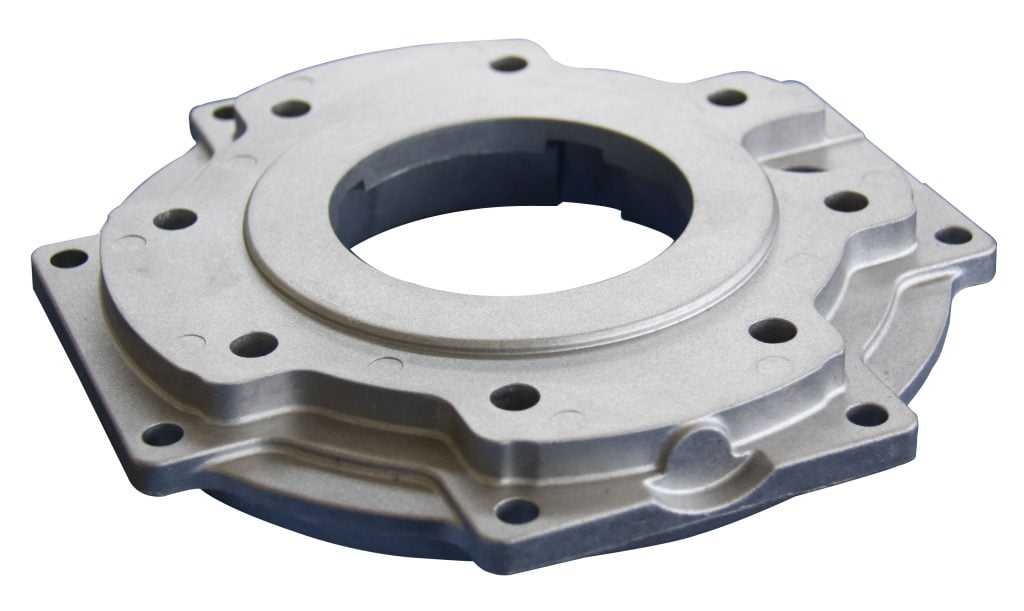

Die casting is a widely used manufacturing process that involves injecting molten metal into a mold cavity under high pressure to produce complex metal components with excellent dimensional accuracy and surface finish. It finds extensive applications across various industries due to its versatility, cost-effectiveness, and ability to produce parts with intricate geometries. However, like any manufacturing process, die castings may also encounter certain defects that can affect the quality of the final product. In this article, we will explore the applications of die castings and delve into the common defects that can occur during the process.

Applications of Die Castings

1. Automotive Industry

The automotive industry extensively utilizes die castings for a wide range of components, including engine blocks, transmission housings, cylinder heads, and structural parts. The high strength, dimensional precision, and cost-effectiveness of die castings make them ideal for mass-producing critical automotive components.

2. Consumer Electronics

Die castings are prevalent in the consumer electronics industry, where they are used for manufacturing components like phone cases, laptop frames, and camera bodies. The ability of die castings to achieve thin walls, tight tolerances, and intricate designs make them suitable for lightweight and aesthetically appealing electronic devices.

3. Aerospace and Defense

In the aerospace and defense sectors, die castings are employed for producing critical components such as aircraft engine parts, housings for avionics, and weapon systems. The lightweight and high-strength characteristics of die castings contribute to fuel efficiency and overall performance in aerospace applications.

4. Lighting Fixtures

Die castings are widely used in the lighting industry for producing fixtures such as lamp bases, housings, and heat sinks. The excellent heat dissipation properties of die castings make them well-suited for high-power LED lighting applications.

5. Household Appliances

Household appliances, including refrigerators, washing machines, and coffee makers, often incorporate die castings for their structural components and housing parts. The use of die castings in appliances ensures durability and precision in their assembly.

6. Medical Equipment

Die castings are utilized in medical equipment for producing parts like imaging machine components, surgical instruments, and patient monitoring devices. The high quality and consistency of die castings are critical in the medical industry for ensuring the safety and reliability of equipment.

Defects in Die Castings

1. Porosity

Porosity is a common defect in die castings and occurs when gas gets trapped in the molten metal during the injection process. This leads to voids or air pockets in the final product, affecting its mechanical properties and structural integrity.

2. Cold Shut

Cold shut occurs when two flow fronts fail to fuse completely during the injection process, resulting in an incomplete fill of the mold cavity. This defect leads to a weak joint or seam in the part.

3. Shrinkage

Shrinkage defects occur when the molten metal cools and contracts, causing voids or depressions in the final product. Proper gating and venting designs are essential to minimize shrinkage defects.

4. Flash

Flash refers to excess material that escapes between the two halves of the mold during the injection process, leading to thin metal projections on the final part. Flash must be removed in post-processing to achieve the desired part dimensions.

Frequently Asked Questions

Q1. What are the common applications of die castings?

Die castings find extensive applications in various industries, including automotive, consumer electronics, aerospace, lighting fixtures, household appliances, and medical equipment. Their ability to produce complex and lightweight parts with high dimensional accuracy and surface finish makes them suitable for a wide range of components across different sectors. In the automotive industry, die castings are used for critical components such as engine blocks and transmission housings. In consumer electronics, they are employed for phone cases, laptop frames, and camera bodies. The aerospace and defense sectors utilize die castings for aircraft engine parts and avionics housings. In the lighting industry, die castings are prevalent for lamp bases and heat sinks. Household appliances, including refrigerators and washing machines, incorporate die castings for their structural components. Medical equipment also benefits from die castings for producing imaging machine components and surgical instruments. The versatility and cost-effectiveness of die castings have made them a popular choice in multiple industries.

Q2. How does the automotive industry benefit from die castings?

The automotive industry benefits significantly from the use of die castings due to the high strength, dimensional precision, and cost-effectiveness of the process. Die castings allow for the mass production of critical automotive components, such as engine blocks, transmission housings, and cylinder heads, at a relatively low cost. The dimensional accuracy of die castings ensures that the components fit perfectly, contributing to the overall efficiency and performance of the vehicle. The ability to produce complex geometries with thin walls allows for lightweight designs, leading to improved fuel efficiency and reduced emissions. Additionally, die castings offer excellent surface finish, reducing the need for additional post-processing and finishing operations, thereby saving time and cost in production. Overall, die castings play a vital role in enhancing the performance, reliability, and cost-effectiveness of automotive components.

Q3. What are the defects that can occur in die castings?

While die castings offer numerous advantages, they may encounter certain defects during the manufacturing process. Some common defects include:

- Porosity: Gas trapped in the molten metal can cause porosity in the final part, leading to reduced mechanical strength.

- Cold Shut: Cold shut occurs when two portions of molten metal fail to fuse completely during the casting process, resulting in incomplete filling of the mold.

- Shrinkage: Shrinkage defects occur when the molten metal cools and contracts, causing voids or depressions in the final product.

- Flash: Excess material escaping from the die-casting mold can cause flash, which needs to be trimmed after the casting process.

Addressing these defects requires careful design of the mold and gating system, proper control of the die casting process parameters, and precise temperature and pressure control. Additionally, post-processing techniques may be employed to remove flash and ensure the part meets the required specifications.

Q4. How can manufacturers address porosity issues in die castings?

Porosity is a common defect in die castings that can compromise the

mechanical properties of the final part. Manufacturers can take several measures to address porosity issues:

- Optimize Die Design: Careful design of the mold and gating system is crucial to minimize the entrapment of gas during the injection process. Proper venting and gating can help in reducing the formation of porosity.

- Metal Quality: Using high-quality raw materials and ensuring proper metal handling and preparation can minimize the presence of impurities that contribute to porosity.

- Process Control: Tight process control, including precise temperature and pressure regulation during injection, can reduce the formation of gas pockets and porosity.

- Post-Casting Treatments: Post-casting treatments, such as vacuum impregnation or pressure infiltration, can be used to fill the pores with a sealing material and improve the part's density and mechanical properties.

Implementing these strategies allows manufacturers to produce die castings with minimal porosity, ensuring that the final parts meet the required quality and performance standards.

Conclusion

Die castings find widespread applications in various industries, providing cost-effective, precise, and reliable solutions for producing complex metal components. However, like any manufacturing process, die castings may encounter certain defects that need to be addressed to ensure the quality and integrity of the final product. By understanding the applications and common defects of die castings, manufacturers can optimize the process, implement appropriate measures to prevent defects, and produce high-quality parts that meet the requirements of diverse industries.