Introduction

Welcome to our blog post on 3D Printing, where we will delve into the aspects of cost, quality, and sustainability. In this article, we'll explore how 3D printing affects sustainability and discuss the costs associated with this innovative technology. Additionally, we'll address the question of whether 3D printing reduces costs. So, let's jump right in!

How does 3D printing affect sustainability?

One of the most captivating aspects of 3D printing is its positive impact on sustainability. Traditional manufacturing methods often result in high material waste and energy consumption. However, 3D printing allows for more efficient use of materials, as it only uses the necessary amount needed for production. This reduces waste significantly and contributes to a more sustainable manufacturing process.

Furthermore, 3D printing encourages localized production, reducing the need for long-distance shipping and storage. This not only reduces transportation-related carbon emissions but also offers economic advantages by cutting down on logistical costs. By enabling on-demand manufacturing, 3D printing minimizes excess inventory and lowers the environmental impact associated with large-scale production.

What costs are associated with 3D printing?

While 3D printing is undoubtedly a revolutionary technology, it's essential to consider the associated costs. The initial investment in 3D printing equipment can be relatively high, particularly for industrial-grade printers. However, with advancements in technology, printer prices have become more accessible to a wider range of users.

Another cost factor to consider is the material used for printing. Although the materials used in 3D printing have become more diverse and affordable, high-performance materials can still be quite expensive. However, the long-term benefits often outweigh the initial costs since 3D printing reduces waste and offers a more efficient process.

Operational costs should also be taken into account, including electricity consumption, maintenance, and post-processing steps. While these costs may vary depending on the scale of operations and type of printer, there are ways to optimize efficiency and reduce expenses, such as using energy-saving settings and streamlining post-processing workflows.

Does 3D printing reduce cost?

3D printing can indeed reduce costs in many scenarios. As mentioned earlier, 3D printing enables localized production, eliminating the need for outsourcing and reducing transportation costs. In some cases, the cost of 3D printing a specific part can be significantly lower compared to traditional manufacturing methods, especially for low-volume production or prototypes.

Moreover, traditional manufacturing techniques often involve complex tooling and molds, which can drive up costs. With 3D printing, these expensive tooling processes can be bypassed, saving both time and money. However, it's worth noting that the cost-effectiveness of 3D printing depends on factors such as the complexity of the design, material selection, and production volume.

In conclusion, 3D printing offers a unique combination of cost-effectiveness, quality, and sustainability. By reducing material waste, enabling localized production, and streamlining workflows, this technology provides a pathway towards more sustainable manufacturing practices. While there are initial investments and ongoing operational costs, the long-term benefits and potential cost savings make 3D printing an attractive option for various industries and applications.

Overview of 3D Printing

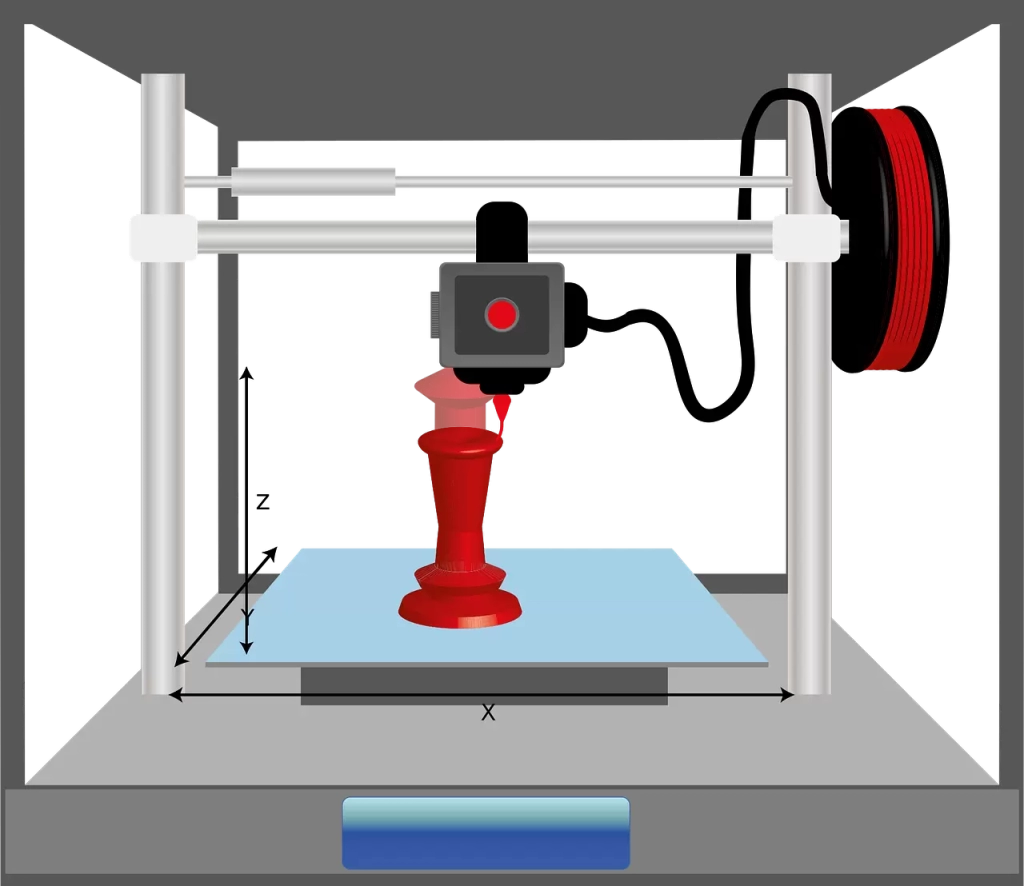

3D printing, also known as additive manufacturing, is a revolutionary technology that has disrupted the traditional manufacturing industry. It is a process of creating three-dimensional objects by adding layers upon layers of material until the desired shape is formed. The concept of 3D printing was first introduced in the mid-1980s, but it was not until recently that it gained significant popularity and adoption in various industries.

Importance of 3D Printing in the Manufacturing Industry

The importance of 3D printing has been realized by many manufacturers due to its ability to produce complex designs quickly and at lower costs than traditional methods. This technology enables designers and engineers to create functional prototypes faster, test them more efficiently, and make changes on-the-go without having to invest significant amounts of time and money into tooling or molds. Furthermore, with advancements in materials science, including biodegradable polymers and recycled plastics, 3D printing can be used for sustainable production practices.

Advantages of 3D Printing

The advantages offered by 3D printing are numerous. Besides enabling rapid prototyping at reduced cost compared to traditional manufacturing methods such as injection molding or CNC machining; other benefits include design freedom (the ability to create complex geometries), customization (production can be tailored according to individual customer requirements), speed (parts can be produced within hours instead weeks or months), waste reduction (since only what's needed for production is printed) among others.

In summary, this introductory section provides an overview of how important 3d-printing has become especially within the manufacturing industry due to its advantages over conventional technologies such as injection molding or CNC machining when producing parts like customized products or fast prototyping while being environmentally friendly too through sustainable production practices using biodegradable polymers/recycled plastics etcetera which further strengthens its place as a must-have tool for any modern-day manufacturer looking towards staying ahead competitively.

Factors Affecting Cost of 3D Printing per Hour

Type of 3D Printing Technology

The type of 3D printing technology selected can significantly affect the cost per hour. Fused Deposition Modeling (FDM) is one of the most common and affordable types of 3D printing technologies. Other technologies such as Stereolithography (SLA) or Selective Laser Sintering (SLS) are more expensive due to their higher precision and material costs, resulting in a higher cost per hour.

Complexity and Size of the Design

Another factor that affects the cost per hour is the complexity and size of the design being printed. A complex design with intricate details will take longer to print than a simple one, increasing labor costs. However, larger designs require more material which also contributes to increased costs.

Material Used

The materials used for 3D printing can have a significant impact on cost per hour as well. The price range for different materials varies greatly depending on their properties, quality, availability, and environmental footprint. For example, filament made from ABS plastic is cheaper than Polycarbonate but requires extra post-processing steps like sanding or smoothing.

Post-Processing Requirements

Post-processing requirements such as polishing or painting add additional time and expense to each project's overall production process hence affecting its hourly rate calculation. Depending on what final product specifications are needed by customers it could require multiple post-processing steps adding up hours that ultimately increase overall production time meaning an increased hourly rate.

While these factors may seem daunting at first glance when considering implementing 3D Printing into manufacturing processes; they provide valuable insight into creating efficient pricing models while maintaining standards in quality control throughout all stages including post-production processing operations since we need not forget about ecological sustainability efforts moving forward within this industry sector too!

Calculation of 3D Printing Cost per Hour

Time-based Cost Calculation

When it comes to calculating the cost of 3D printing, time is a crucial factor. The longer a print takes, the more expensive it becomes. Therefore, manufacturers need to take into account the length of time required for each print job in order to calculate an accurate hourly rate. This includes not only the actual printing time but also pre-printing preparations such as bed leveling and post-printing tasks like removing supports.

Material-based Cost Calculation

Another important consideration when calculating 3D printing costs is material usage. Different types of filament or resin will have varying price points and different levels of waste or leftover material that can affect overall costs. Manufacturers must carefully track how much material they use in each print job and determine its cost per unit in order to accurately calculate their total expenses.

Overhead and Labor Costs

In addition to direct costs associated with materials and time spent on each individual print job, there are other overhead expenses that contribute to overall 3D printing costs. These might include rent for workspace or equipment leasing fees, electricity bills, software licensing fees, maintenance and repair costs for printers themselves, employee salaries or wages for operators who oversee production processes.

By taking all these factors into account - including both direct materials/labor inputs as well as overhead expenses - manufacturing professionals can arrive at a comprehensive understanding of their true cost per hour for 3D printing services. And by having this information at hand they'll be better equipped make strategic decisions about pricing structures that reflect sustainable business practices while still meeting customer needs over the long-term future success of their enterprise

Equipment and Machinery Used for 3D Printing

3D Printer Types and Capabilities

There are several different types of 3D printers available on the market. Each printer type has its own unique capabilities, strengths, and weaknesses. Fused Deposition Modeling (FDM) is one of the most popular types of printers for hobbyists as it is relatively affordable. It works by heating up plastic filaments until they melt and then depositing them layer-by-layer to create a three-dimensional object.

Stereolithography (SLA) uses a liquid resin that hardens when exposed to UV light to create objects with finer details than FDM printers can produce. Selective Laser Sintering (SLS) uses lasers to fuse powdered materials together, creating highly detailed objects from metals or plastics.

Auxiliary Equipment

In addition to the printer itself, auxiliary equipment such as scanners and software are required for successful 3D printing projects. Scanners allow users to scan existing objects in order to replicate them using their 3D printers. Software used in conjunction with these machines plays an important role in designing parts before they are actually printed.

Maintenance and Repair

As with any piece of machinery, regular maintenance is necessary for optimal performance of a 3D printer. Routine cleaning should be performed on all parts that come into contact with the printing material, including nozzles and extruder heads.

It's also important for manufacturers or individuals who use these machines often to keep spare parts on hand in case repairs become necessary at some point down the line. Many manufacturers provide online tutorials or other resources that offer guidance on how best to maintain their specific models so users can ensure maximum longevity out of their investment.

Overall, investing in high-quality equipment will result in higher quality prints while minimizing downtime due repair issues caused by low-quality components failing over time which results ultimately lower costs associated with long-term ownership sustainability concerns like cost-effectiveness & reliability factors need consideration when choosing between different models of 3D printers.

Design for 3D Printing

Design Guidelines for Additive Manufacturing

When it comes to 3D printing, the design is critical. Unlike traditional manufacturing methods where designs can be adjusted during production, 3D printing requires precise digital models that are ready to print. Therefore, designing for additive manufacturing (AM) requires a different approach than designing for subtractive or injection molding processes. Designers must consider factors such as layer thickness, orientation, and support structure when creating their parts.

To ensure high-quality prints without wasting material or time, designers should follow specific guidelines for AM. These guidelines include keeping overhang angles below 45 degrees and minimizing the use of unsupported horizontal features in their designs. By following these guidelines, designers can create parts that meet functional requirements while also being optimized for the 3D printing process.

Tolerance Design

Another essential aspect of designing for 3D printing is tolerance design. Since every machine has its unique set of limitations and capabilities, designers must understand how to adjust tolerances in their models correctly. This means considering factors like shrinkage rates and thermal expansion when creating parts with tight tolerances.

It's important to note that some materials used in 3D printing have more significant variations compared to traditional manufacturing materials due to differences in heat transfer rates throughout the build volume or inconsistencies between batches from suppliers. Therefore understanding this variation helps engineers optimize part dimensions so they fit precisely together when assembled.

Support Structure Design

Support structures play a crucial role in ensuring successful prints by providing stability during the build process while reducing warping caused by overheating or other issues related to geometry optimization challenges inherent with layer-by-layer deposition technology’s nature of adding material on top of itself one layer at a time until reaching completion - which typically takes hours depending on complexity level involved- The right support structure will help prevent distortion while maintaining accuracy within tolerance ranges defined earlier mentioned above sections about AM Guideline & Tolerance Designs considerations; however poorly designed support structures can lead to poor surface finishes and wasted materials.

To optimize support structure design, engineers must consider factors such as print orientation and material selection. They should also aim to minimize the use of supports where possible since they add time, cost, and complexity to the printing process.

Quality Control and Assurance for 3D Printing

Implementing Quality Control Processes and Attaining Quality Assurance Certifications for 3D Printing

In order to achieve high-quality output from 3D printing, it is essential to have a robust quality control process in place. The process involves inspecting each component of the production process and ensuring that they meet the required standards. For instance, before starting a print job, the operator should ensure that all materials are correctly loaded into the printer. They should also check if there are any signs of wear or damage on components such as nozzles or belts.

To maintain consistency across various batches of prints, it is advisable to create a standard operating procedure (SOP) for quality assurance purposes. An SOP outlines the critical steps involved in producing a successful print and can be used as a guide when troubleshooting issues during production.

Additionally, manufacturers can attain quality assurance certifications such as ISO 9001:2015 which demonstrate their commitment to meeting customer requirements consistently. These certifications provide reassurance to customers that products produced through 3D printing meet specific criteria consistently.

Choosing the Right 3D Printing Material

Factors to Consider

When it comes to choosing the right material for 3D printing, there are several factors that need to be considered. One of the most important considerations is the mechanical properties of the material. Depending on what you are planning to use your 3D printed object for, you may need a material with high strength or flexibility. Other factors include temperature resistance and chemical compatibility.

Another consideration is cost. Some materials can be expensive, so it's important to balance cost against performance requirements. Additionally, some materials may require specialized equipment or processes which can add additional costs.

Due Diligence

Before selecting a particular material for your 3D printing project, it's important to do your due diligence and research the options available in order to make an informed decision. This includes understanding the characteristics of different types of materials as well as their strengths and weaknesses.

It’s also beneficial to consult with experts in 3D printing who can offer guidance on which materials would work best given specific parameters such as budget constraints or desired outcomes.

Negotiations and Contracts

Once you've selected a particular material for your project, negotiations around pricing and delivery timelines should take place between suppliers before finalizing any agreements. In addition, contracts should be reviewed carefully before signing them in order ensure all aspects are aligned with expectations set forth by both parties involved.

In summary, selecting the right material for 3D printing requires careful consideration of numerous factors including performance requirements vs cost tradeoffs., conducting thorough research prior making decisions based upon informed choices from consulting experts familiar with industry trends while being mindful about negotiating favorable terms when engaging suppliers through contract agreements signed-off after review process takes place among stakeholders involved ensuring maximum transparency into every aspect related towards delivering successful projects using this cutting-edge technology!

Lead Times and Costs

Lead Times for Prototype and Production Orders

One of the biggest advantages that 3D printing offers is its ability to significantly reduce lead times. Traditional manufacturing processes can take weeks or even months to produce a prototype or final product, whereas 3D printing can create parts in a matter of hours. This is because the design process is simplified with 3D printing as there are no tooling costs which need to be factored into production time. Additionally, if changes need to be made during the prototyping phase, they can easily be implemented without any expensive retooling.

Costs for 3D Printing

While it’s true that 3D printing has become more affordable in recent years, it still remains more expensive than traditional forms of manufacturing when producing large quantities. The cost per part decreases as batch sizes increase with traditional methods but this isn’t always possible with additive manufacturing such as 3D printing where each layer must be printed individually regardless of quantity being produced. However, when it comes to smaller runs or custom parts, 3D printing can actually end up being less costly than traditional methods due to lower overheads and low set-up costs.

It’s important for manufacturers looking at implementing additive manufacturing methods such as 3D printing into their production lineups understand how these factors will affect their bottom lines before making decisions about whether or not this technology is right for them.

Environmental Impact and Sustainability

Reducing Waste Generation

One of the biggest advantages of 3D printing is its ability to reduce waste generation during manufacturing. Traditional manufacturing processes often produce a lot of excess material that is discarded as scrap, which contributes to environmental pollution and increases production costs. With 3D printing, however, only the necessary amount of material is used for each part or product, resulting in significantly less waste.

Energy-efficient Manufacturing Practices

In addition to reducing waste generation, 3D printing can also be more energy-efficient than traditional manufacturing methods. For example, many 3D printers use less energy overall than injection molding machines or CNC machines. Additionally, because parts are printed layer by layer instead of being cut from larger pieces of material, there is no need for extensive tooling or machining operations that consume significant amounts of energy.

Sustainable Material Selection

Finally, sustainability can be further enhanced through careful selection and use of materials in the 3D printing process. Some companies are exploring the use of biodegradable or recycled materials for their products and prototypes. Others are experimenting with new types of materials made from renewable resources like cornstarch or algae-based polymers. These innovative approaches not only help reduce environmental impact but also promote sustainability throughout the entire supply chain.

Overall, these factors demonstrate how important it is to consider environmental impact and sustainability when choosing a manufacturing method like 3D printing. By incorporating these principles into our design and production processes we can reduce waste generation and energy consumption while creating high-quality products that meet customer needs without compromising on quality or cost efficiency – truly a win-win situation!

Applications of 3D Printing

Automotive Industry

One of the most popular applications of 3D printing is in the automotive industry. It has revolutionized the way automobile manufacturers design and produce parts for their vehicles. With 3D printing, it is now possible to create complex geometries with ease, which was not possible earlier. Additionally, 3D printing allows carmakers to reduce lead time and cost associated with traditional manufacturing methods.

Aerospace Industry

The aerospace industry is another sector that has gained immense benefits from 3D printing technology. In this industry, parts are often required to be lightweight yet strong enough to withstand extreme conditions such as high-speed air travel or space missions. Using traditional manufacturing techniques, producing such components can be a daunting task; however, with 3D printing's help, creating high-performance components that meet these requirements has become achievable.

Consumer Products Industry

The consumer products industry is also leveraging on 3D printing technology by enabling mass customization of products at scale and reducing production costs significantly. Companies can easily create customized designs for individual customers based on their unique needs while keeping the overall production cost low.

Medical Industry

In recent years there have been significant advancements in medical procedures due to the use of 3D Printing Technology. This process allows doctors to print patient-specific implants quickly and accurately by utilizing various materials like titanium alloys or biocompatible plastics derived from renewable resources like cornstarch or sugar cane waste.

Overall, looking at how versatile this tech can be in different industries makes us believe that its future potential will only keep growing due to its limitless possibilities!

Future Trends and Developments in 3D Printing

Advancements in Materials and Technologies

The 3D printing industry is continuously evolving, and advancements in materials and technologies are driving its growth. With the increasing demand for high-quality products, manufacturers are exploring new materials that can be used for 3D printing. Engineers are experimenting with various metals, plastics, ceramics, and composites to achieve greater strength, durability, flexibility, and biocompatibility.

In addition to material innovations, there have been significant technological improvements in 3D printing as well. The latest printers can produce objects with intricate geometries at a faster speed than before. Coupled with software developments such as AI-driven generative design tools that create optimized designs based on performance requirements; these advancements will enable engineers to create complex structures that were previously not possible.

Sustainable and Circular Economy Manufacturing

Sustainability has become increasingly important in manufacturing worldwide due to environmental concerns. Traditional manufacturing methods generate a lot of waste which eventually ends up polluting our environment. However, 3D printing is an eco-friendly alternative because it generates less waste by producing only what is needed using recyclable feedstocks.

Moreover ,Circular economy principles could be incorporated into the production process through remanufacturing or refurbishing used parts instead of discarding them entirely.This approach leads to more sustainable consumption patterns while also reducing costs for businesses.

Industry 4.0 in 3D Printing

Industry 4.0 refers to the fourth industrial revolution where machines become smart enough to work autonomously without human intervention.Through automation and interconnectedness,it increases efficiency,reduces waste,and improves product quality.Incorporating Industry 4.0 technology into the field of additive manufacturing enables greater control over production processes while minimizing errors caused by manual labor.

Furthermore,the integration of data analytics within additive manufacturing allows companies to monitor their supply chains closely which helps identify bottlenecks or inefficiencies quickly.The combination of advanced machinery coupled with intelligent systems creates smarter production systems that can adapt to customer needs in real-time.

Conclusion

After considering the cost, quality and sustainability of 3D printing, it is clear that this technology has great potential for manufacturing professionals and engineers. Although initial investment costs may be high, the long-term benefits in terms of reduced waste and increased efficiency are worth it. By optimizing designs to minimize material usage and choosing sustainable materials such as bioplastics or recycled plastics, 3D printing can also contribute positively to the environment. To fully benefit from 3D printing services, manufacturers should seek out experienced professionals with expertise in design optimization and material selection. With careful consideration of these factors, 3D printing can revolutionize the manufacturing industry by providing faster production times at a lower cost while reducing environmental impact.

In recent years, 3D printing has emerged as a groundbreaking technology with the potential to revolutionize multiple industries. Beyond its rapid prototyping capabilities and manufacturing potential, the positive impacts of 3D printing on sustainability have garnered significant attention. In this blog post, we will delve into the ways 3D printing affects sustainability, the sustainability benefits it offers, and an evaluation of its overall eco-friendliness.

- How Does 3D Printing Affect Sustainability?

3D printing, also known as additive manufacturing, differs significantly from traditional manufacturing methods like injection molding or subtractive manufacturing. Its fundamental approach of layer-by-layer material deposition results in reduced waste production. Unlike traditional methods that often involve removing or discarding excess materials, 3D printing only uses the exact amount of material needed for the specific object being created, minimizing waste and conserving resources.

Moreover, 3D printing allows for localized production, eliminating the need for long-distance transportation of goods. This reduction in transportation not only saves on fuel consumption but also lowers the associated greenhouse gas emissions, making 3D printing a greener option for manufacturing and distribution.

- Sustainability Benefits of 3D Printing

a. Waste Reduction: As mentioned earlier, 3D printing generates significantly less waste compared to traditional manufacturing methods. By using only the required materials, it minimizes both raw material consumption and post-production waste, leading to more sustainable production processes.

b. Energy Efficiency: Traditional manufacturing processes often involve numerous steps and machinery, consuming substantial amounts of energy. Conversely, 3D printing is more energy-efficient as it directly builds the final product, omitting the need for complex tooling and reducing overall energy consumption.

c. Design Optimization: 3D printing enables the creation of intricate and lightweight designs, which can improve the overall energy efficiency of products. By producing complex geometries that are otherwise challenging to manufacture, the technology promotes innovative design solutions that minimize material usage without compromising functionality.

d. On-Demand Production: The ability to produce items on-demand allows for a leaner inventory system, leading to reduced storage and warehousing needs. This decentralized approach optimizes the supply chain, resulting in further resource savings and reducing the environmental impact.

e. Sustainable Materials: As the 3D printing industry evolves, there is a growing focus on developing and using sustainable and biodegradable materials. From recycled plastics to bio-based resins, researchers and manufacturers are exploring eco-friendly alternatives that can enhance the sustainability of 3D printing even further.

- How Sustainable is 3D Printing?

While 3D printing offers numerous sustainability benefits, it is essential to address its limitations and challenges. As with any technology, sustainability is a multifaceted consideration that extends beyond a single aspect.

a. Energy Sources: The sustainability of 3D printing heavily depends on the energy sources used for powering the printers. If the electricity comes from fossil fuels, the environmental benefits of 3D printing may be diminished. However, as renewable energy adoption increases, the eco-friendliness of 3D printing can also improve significantly.

b. Material Recycling: Although 3D printing produces less waste during production, recycling end-of-life printed objects can be a challenge. Developing efficient and cost-effective recycling methods for printed parts and materials is crucial to bolstering the sustainability of the technology.

c. Limited Applicability: 3D printing is not a one-size-fits-all solution, and there are instances where traditional manufacturing methods may still be more sustainable. Understanding the strengths and limitations of 3D printing is essential in making informed decisions about its implementation.