What is 3d printing rapid prototyping technology

What is 3d printing technology? To be precise, 3D rapid prototyping is one of many rapid prototyping technologies. Rapid prototyping technologies can be broadly classified into seven categories, including three-dimensional printing, stacked solid manufacturing, selective laser sintering, fused deposition forming, three-dimensional welding, three-dimensional printing, and digital cumulative forming.

3D printing rapid prototyping technology is an advanced additive manufacturing process that allows for the rapid creation of physical prototypes directly from digital 3D models. It has revolutionized the product development and manufacturing industries by enabling faster and more cost-effective prototyping, which helps in accelerating the design iteration and validation process. In the context of rapid prototyping, 3D printing is often used interchangeably with additive manufacturing, as both terms refer to the same technology.

How 3D Printing Rapid Prototyping Works

The process of 3D printing rapid prototyping involves the following steps:

- Creating a 3D Model: The first step is to design a 3D model of the desired product using computer-aided design (CAD) software. The CAD model serves as the digital blueprint for the physical prototype.

- Slicing the 3D Model: The 3D model is then sliced into thin horizontal layers using slicing software. This step generates the necessary instructions for the 3D printer to build the prototype layer by layer.

- Printing the Prototype: The 3D printer interprets the sliced design and begins the printing process. Depending on the specific 3D printing technology used, the printer deposits or solidifies the chosen material, layer by layer, to build up the final prototype.

- Post-Processing (Optional): Depending on the printing technology and the desired properties of the prototype, post-processing may be required. Post-processing can include cleaning, removing support structures, surface finishing, or additional treatments to achieve the desired characteristics of the prototype.

Advantages of 3d printing technology

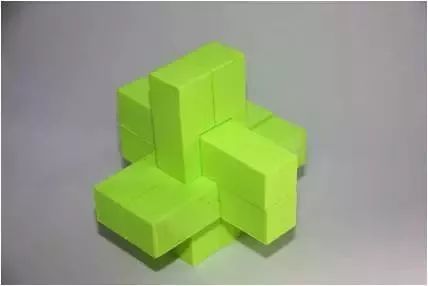

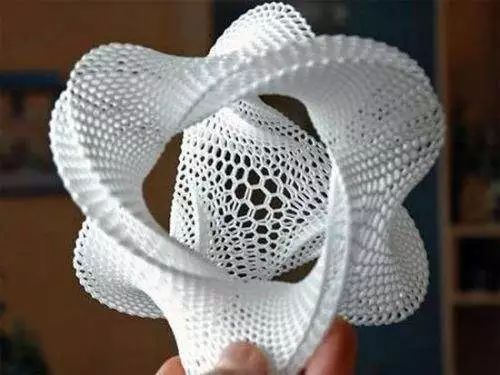

3d printing is very different from traditional production through moulds. The biggest advantage of 3d printing is that it can generate parts of any shape directly from computer graphics data without mechanical processing or any moulds, thus greatly reducing the product development cycle, increasing productivity and reducing production costs. At the same time, 3d printing is also able to print shapes that cannot be produced by traditional production techniques. 3d printing technology is also able to simplify the entire production process and is fast and efficient.

Principle of the 3d printing technology process

The 3D printer, guided by design file instructions, first ejects a solid powder or molten liquid material that cures into one special flat, thin layer. After the first layer has cured, the 3D printer head returns and forms another thin layer on the outside of the first layer. After the second layer has cured, the print head returns again and forms another layer on the outside of the second layer.

This is repeated, with the final layers accumulating into a 3D object. Unlike traditional manufacturing machines that shape objects by cutting or moulding, 3D printers expand the scope of digital concepts from a physical perspective by forming solid objects by stacking layers on top of each other.

For designs requiring shapes with precise pairs of internal depressions or interlocking parts, 3D printers are the preferred processing equipment to bring such designs to life in the physical world.

Due to the high printing precision, the quality of the printed models is naturally good. As well as being able to represent designs on form curves, structures and moving parts are also not a problem.

3D printing has brought about a worldwide revolution in manufacturing, as the design of a part was previously entirely dependent on the production process, and the advent of 3D printers will overturn this production mindset, allowing companies to produce parts without regard to the production process, as any complex shape can be realised with a 3D printer. 3D printing is able to produce objects of any shape directly from computer graphics data without the need for machining or moulds, thus significantly reducing the production cycle time and increasing productivity. Although still in need of refinement, the market for 3D printing technology has huge potential and is set to become one of the many breakthrough technologies for the future of manufacturing.

Engineering manufacturing. In engineering manufacturing, on the one hand, it is used in the production of important components for defence and military, aerospace and other high-end manufacturing, which are produced with high requirements and often cannot be reached by traditional processes or even if they are reached but the cost is too high; on the other hand, it is used in the production of small batches or single products for engineering manufacturing.

Civil development. In terms of civil development, 3D printing technology has been hailed as the core technology of the "third industrial revolution", bringing about profound changes in manufacturing processes while reducing labour costs.

Medical. 3D printing technology is also having a significant impact on the medical sector, as it can be used to print prosthetic limbs, helping more people who have lost their legs in accidents to get back on their feet and live like normal people. The "3D printed heart" is another achievement in the application of 3D printing technology for the replication of human organs. The 3D printed heart can be used as a replica of a heart anatomy and will be useful for practising complex heart surgery. It is also possible to print "kidney organs", but these technologies are not yet mature.

The construction industry. The potential of 3D printing goes far beyond the production of DIY household items, with significant achievements in the construction industry. In fact, the technology could even revolutionise the traditional construction industry. Compared to the traditional construction industry, 3D printed buildings not only have reliable quality building materials, but can also save 30%-60% on construction materials, shorten the construction period by 50%-70% and reduce labour by 50%-80% …… According to estimates, printing can reduce construction costs by at least 50%, allowing more people to afford to live in a house. However, the new "ink" printed building, its stiffness, strength and durability and other comprehensive performance is still to be further verified.

3D printing has made it possible to buy such printers in some electronics shops, and factories are selling them directly. Scientists say that the use of 3D printers is still limited, but one day in the future people will be able to print more practical items with 3D printers.

3D printing technology is vital to NASA's space exploration missions, and more than 30% of the existing spare parts for the International Space Station could be made by this 3D printer. The machine will use polymers and other materials to manufacture items layer by layer using extrusion incremental manufacturing techniques. 3D printing experiments are one of NASA's future research priorities, and 3D printed parts and tools will increase the reliability and safety of space missions, while reducing the cost of space missions as they do not have to be transported from Earth.