2K Injection Molding Services

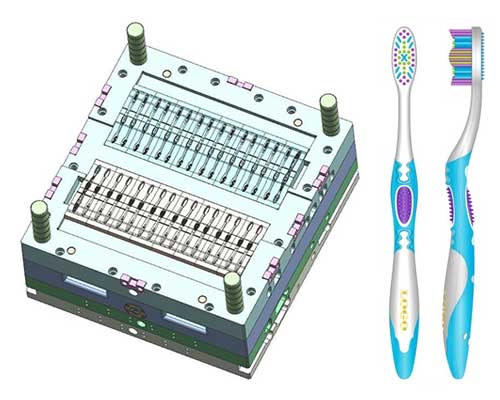

Two-color or Multi-color Injection mould manufacturing, V1 has 16 years Double Shot Plastics mold production experience for Global customers.

2K Injection Molding Processing capacity

2k injection molding (Two-shot injection) Service

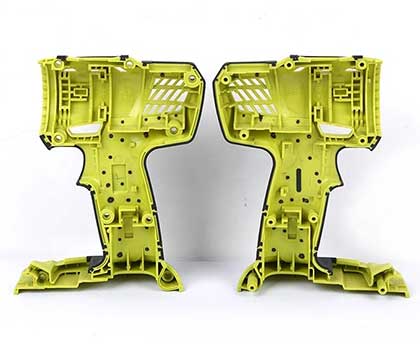

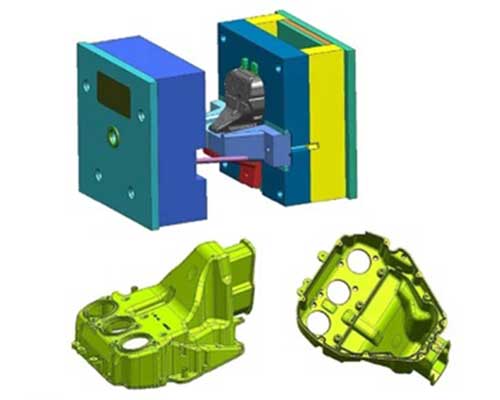

2k injection molding is a manufacturing process used when referring to molding two materials/colors into one plastic part. This plastic molding technology blends two materials or two different colours materials into one ending plastic part by using 2k injection molding machine.

The chemical bonding process involved in this process takes place because they are able to merge two or more material into one part. When using 2k injection molding technology process, the material selection will be the key point factor to the success of the project or not.

This is an industrial activity that entails directing two totally opposite polymers into a ready product.

Advantages of 2K Plastic injection molding

The parts are strongly fitted and molded thus components or rather end products become more durable.

The appearance in terms of aesthetic value or beauty is high since many colours can be blended in the molding stages.

There are reduced costs since all manufacturing procedures are completed in the injection stage.

Finally, custom made products can be made to suit the user’s preferences

Differences between the 2K injection molding and over molding

Over molding is for some small scale production volume compared to the 2k injection which is majorly large production scale.

With the over molding process, for another process to happen, the material used to mold must get cold to be removed whereas.

With 2K injection molding it is different. The polymer is usually still hot and flexible; hence more operations can still be carried out.

Once an object is made using over-molding it is locked mechanically with the other substances whereas it forms a chemical bond that entails its molecules bonding in 2k injection molding.

The 2K injection molding procedure can house diverse ideas such as the use of many different materials thus high-quality end product, opposed to the 2K injection molding procedure, the over molding activity can have some compatibility issues more so plastics.

When over molding, you are restricted to over-molding a metal with a plastic a few cases of a plastic and a plastic.

While in 2K injection molding there is a wide range of materials that can act as the molding substance or be molded on.

2K Injection Molding Manufacturing FAQs

2K injection molding is a process in which two different materials (usually two colors) are injected into one part.