Custom Plastic & Metal Rapid Prototype, High Quality Mass batch production.

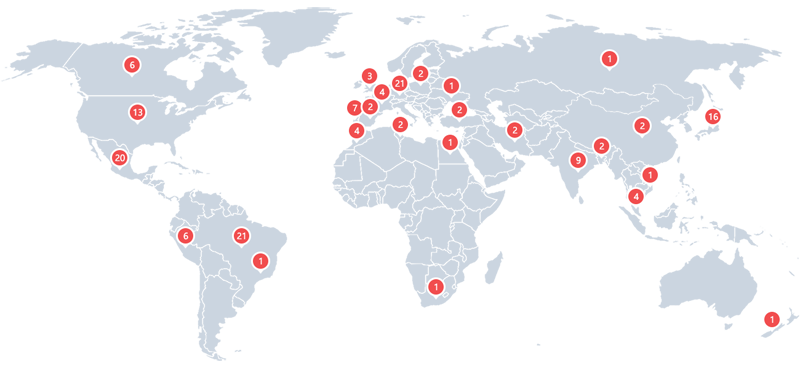

Over 3500 companies in 57 countries use V1 prototype, high quality 3D printing, CNC machining, Mold making, Injection molding, Die Casting solutions to reduce costs and time to market.

Professional rapid prototype services

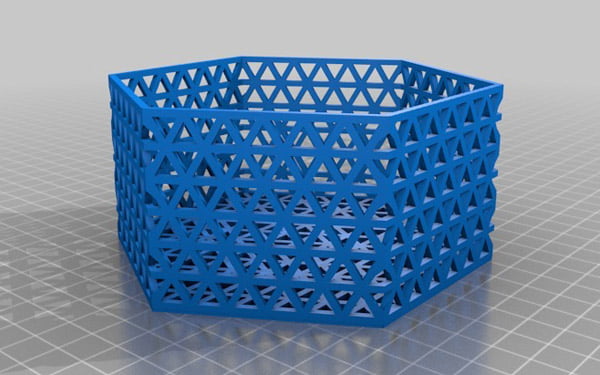

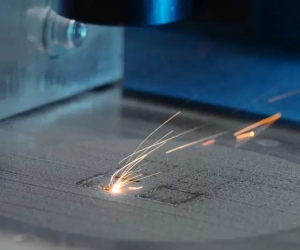

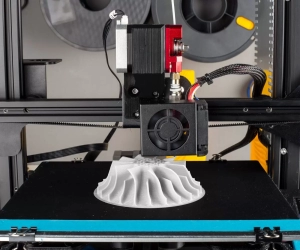

3D Printing Service: We offer high-quality, fast and affordable 3D printing solutions for various industries and applications. Contact us today for a free quote.

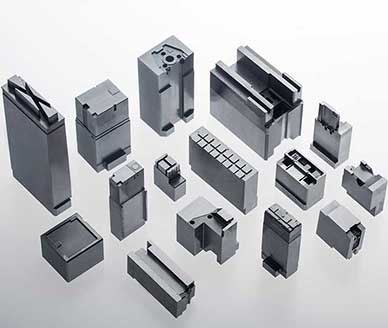

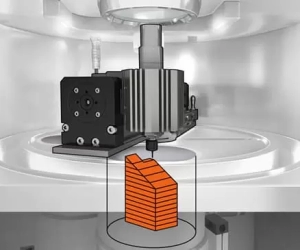

Precision CNC Machining service provides high-quality custom parts with tight tolerances and fast turnaround times. Contact us for a free quote today.

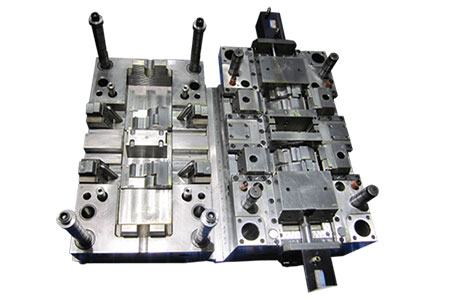

Rapid tooling service is a process that uses 3D printing or CNC machining to create custom molds or prototypes in a short time. It is suitable for low-volume production or testing purposes.

Plastic & Metal Batch Production

Plastic mold making is a process of manufacturing plastic products that involves creating a physical mold of a designed shape, using it to produce plastic products with the desired shape and size.

Plastic injection molding service is a process of producing plastic parts by injecting molten plastic into a mold. It is fast, precise and cost-effective.

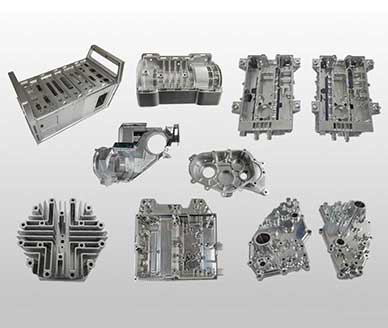

Metal die casting service is a process of creating metal parts by injecting molten metal into a mold. It offers high precision, durability and cost-effectiveness for various industries.

Strong Rapid Prototyping Capabilities

One-stop rapid prototype + medium and mass batch customization

Rapid prototypes

3D printing – CNC prototyping

CNC small batch manufacturing in various of engineering plastics and aluminum alloys

Medium and Mass batch production with multiple machining integration

Trial & Plastic Injection Molding & Metal Die Casting Assembly

V1 order management system can help customers and suppliers track order status and improve order processing efficiency. It can also help companies manage inventory and production planning to ensure timely delivery of products. Order management systems for rapid prototyping, machining and mold injection industries usually have the following characteristics:

- Automatic quotation: According to the 3D model and material type provided by the customer, the quotation is automatically generated, which greatly improves the quotation efficiency.

- Order Tracking: Customers can keep track of the progress of their orders, thereby increasing customer satisfaction.

- Production plan: According to the order quantity and production capacity, the production plan is automatically generated to improve production efficiency.

- Inventory management: manage raw material inventory and finished product inventory to ensure timely delivery of products.

Our product and parts customization business has a professional service team around the world, committed to providing customers with high-quality, customized solutions. Our team members have rich industry experience and technical expertise, and can provide professional advice and high-quality services according to the specific needs and requirements of customers.

No matter where you are, whether you need to customize a single part or a large batch of products, our team can contact and communicate with you through the platform, track the progress of the project throughout the process, and ensure the smooth progress of the customization process of products and parts. V1 has advanced production equipment and technology, can quickly respond to customer needs and provide efficient production services.

Gallery of Plastics & Metal Parts Products

V1 Rapid Prototype helping people make parts and products in 2006. We offer in terms of quality and service and with the aim to become the fastest and most dependable in the world.

As our company and customer base has grown so has our range of services. We are now one of the only companies in the world to offer such a massive range of prototyping and bespoke low volume manufacturing solutions all under one roof. Our high tech rapid prototyping and production facilities include CNC milling, 3D printing (SLA and SLS), vacuum casting (cast urethanes), sheet metal and rapid tooling and injection molding as well as traditional model making and a range of finishing techniques.